Special paint spray room cleaning device for effectively purifying and preventing clogging

A purification device and anti-clogging technology, applied in chemical instruments and methods, gas treatment, membrane technology, etc., can solve the problems of low exhaust gas content in local locations, shortened service life of exhaust gas treatment devices, and difficulty in meeting emission standards for exhaust gas, and achieves a high level of improvement. Adsorption treatment effect, enhanced purification effect, prolonged residence time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

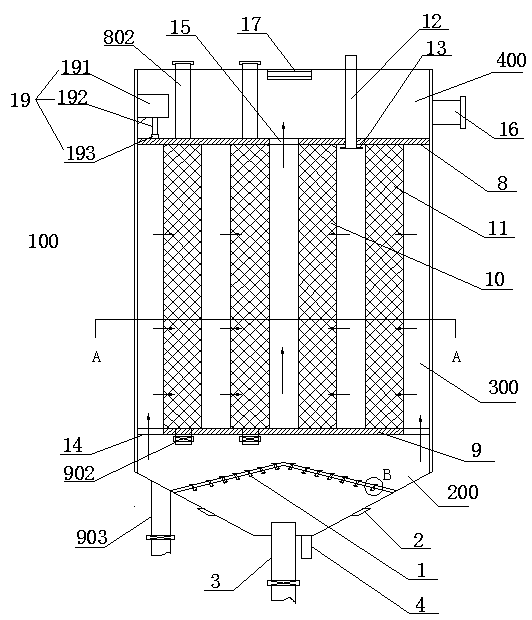

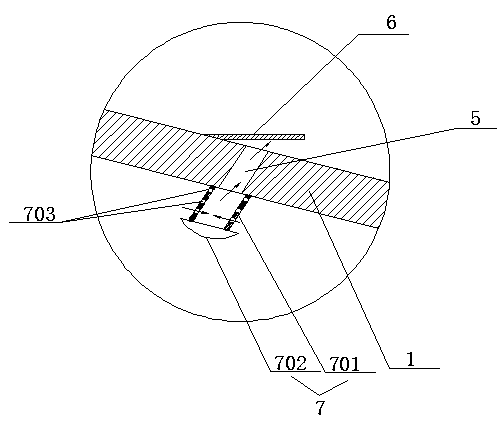

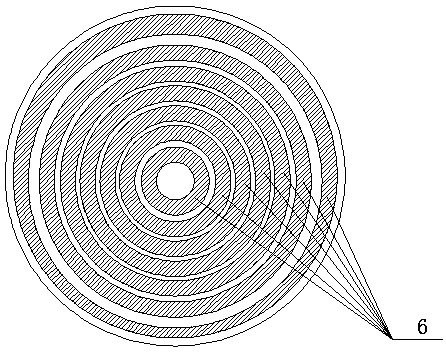

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 Shown is a special purification device for effective purification and anti-clogging spray booth, the treatment device of the present invention is dedicated to the treatment of exhaust gas in the spray booth, and the exhaust gas in the spray booth is connected to the treatment device of the present invention through an air pump.

[0027] The special purification device for effective purification and anti-clogging paint spraying room of the present invention includes a vertical purification tower 100, the tower body is divided into a conical inlet chamber 200, a purification chamber 300, and an air outlet chamber 400 in sequence from bottom to top, and waste gas enters from the inlet chamber. It is purified by the clean room, and then discharged from the air outlet room to realize the adsorption and purification of waste gas. In the present invention, the adsorbent adopts activate...

Embodiment 2

[0038] Such as Figure 8 As shown, the cross-section of the vertical purification tower in this embodiment is square, the cross-section of the mesh interlayer of the inner purification layer is back-shaped, and the cross-section of the mesh interlayer of the outer purification layer is back-shaped. The back-shaped setting has a similar technical effect to the ring-shaped setting, and the shape of the purification layer is reasonably set according to the shape of the tower body to achieve a good purification effect.

[0039] The rest of the structure is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com