Textile machine bobbin

A mechanical bobbin and textile technology, which is applied in the field of textile machinery bobbins, can solve the problems of yarns that are difficult to distinguish thread number, color number, yarn ends cannot be fixed, and are entangled with each other, so as to achieve reasonable structure and improve production Efficiency, effect of preventing loose yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

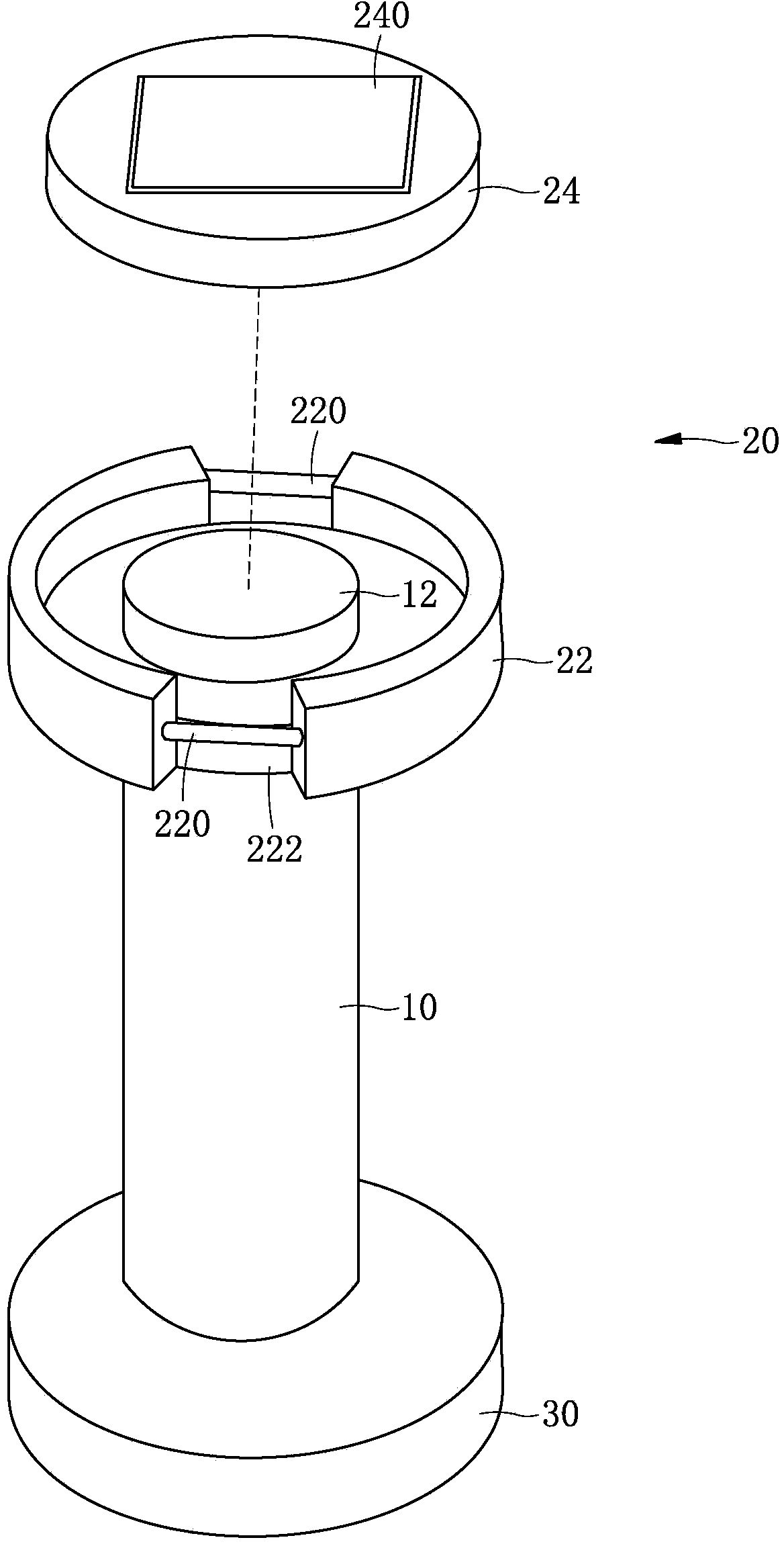

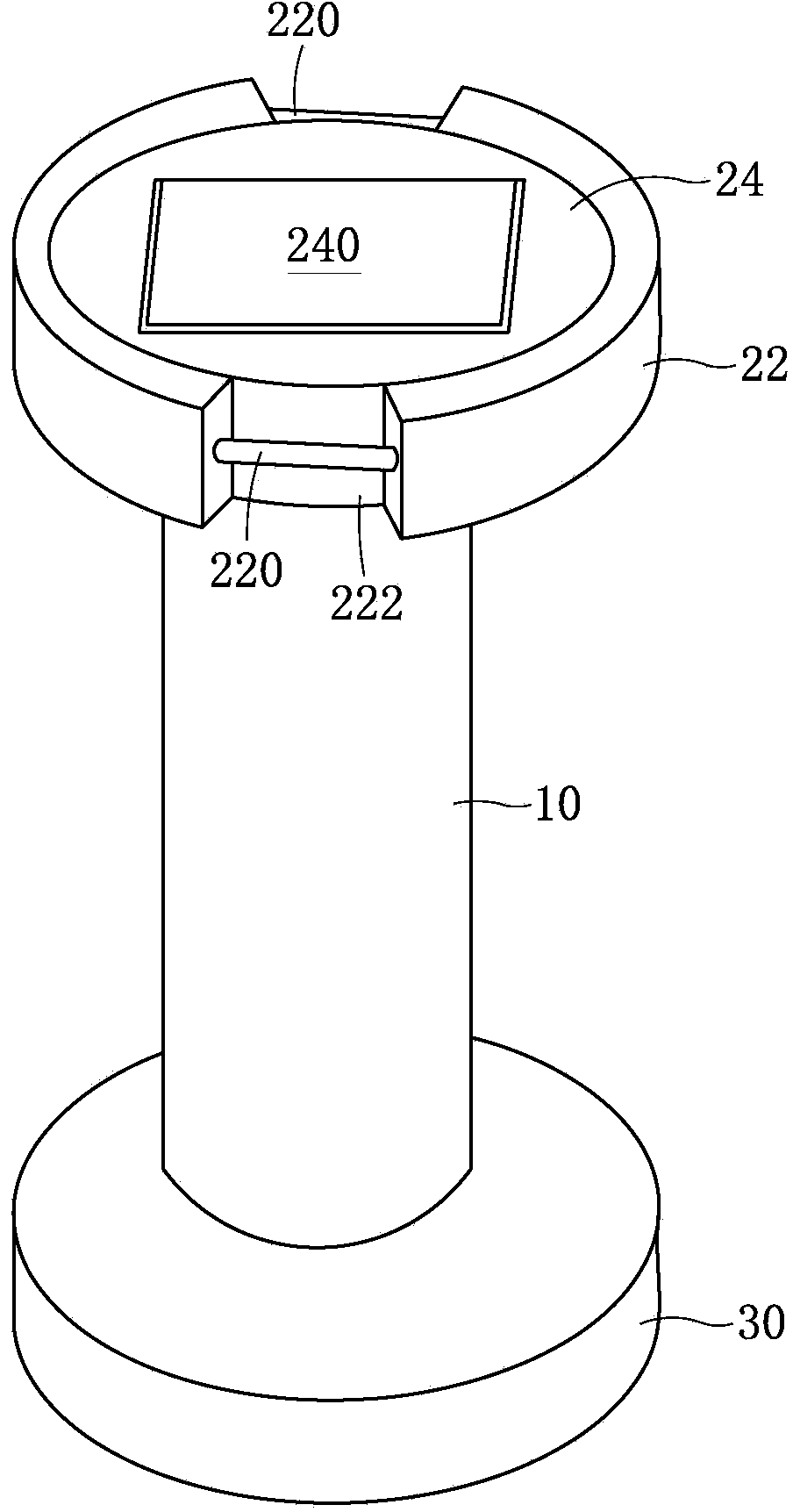

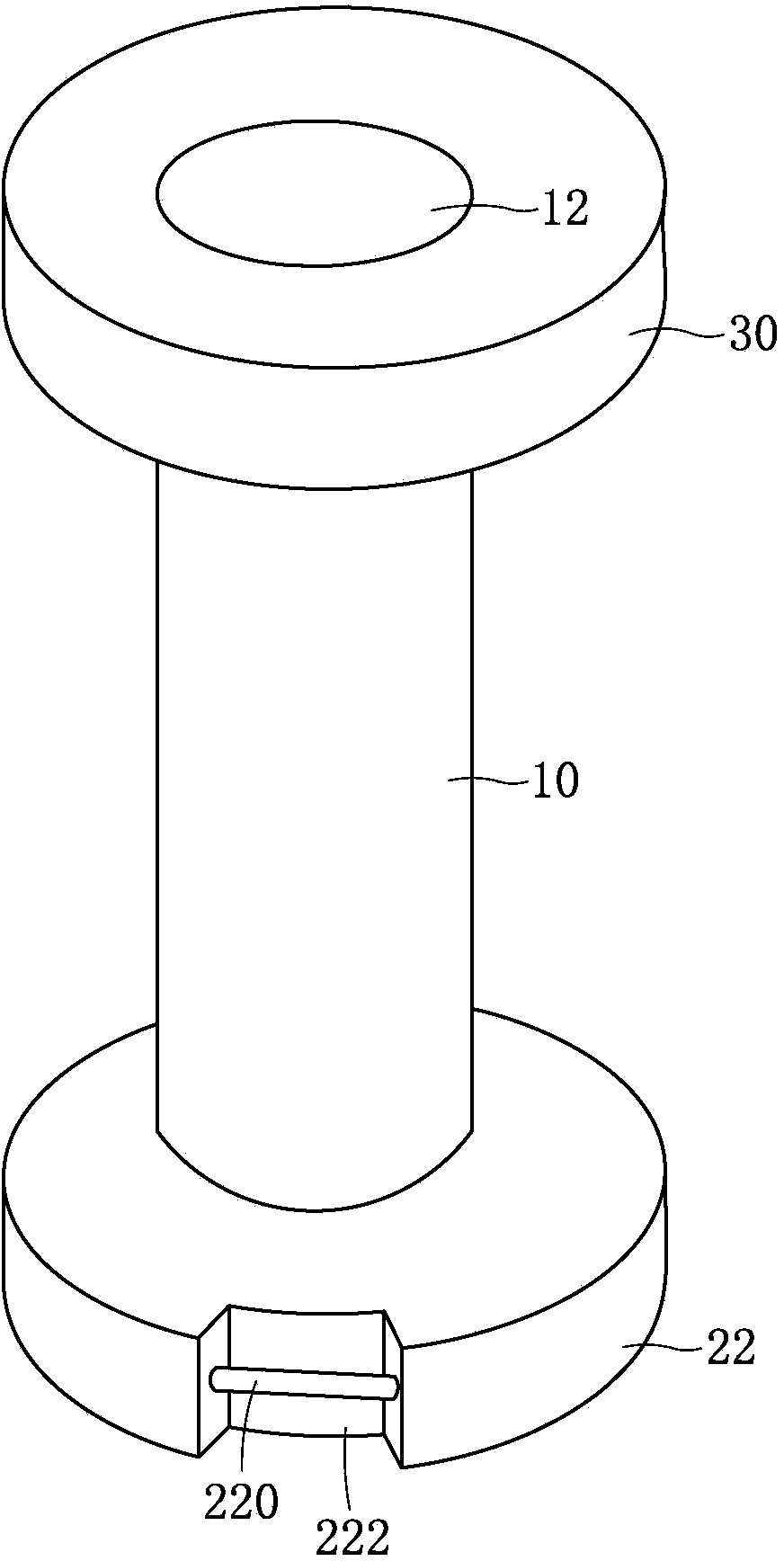

[0022] like figure 1 , figure 2 and image 3 Commonly shown, a textile machinery bobbin comprises a cylindrical tube body 10, the center of the tube body 10 is provided with a shaft hole 12 that runs through both ends of the tube body 10, and a first side plate 20 is fixed on one end of the tube body 10. The other end of the body 10 is fixed with a second side plate 30 , and the shaft hole 12 extends to the outside of the first side plate 20 and the second side plate 30 .

[0023] like figure 1 and figure 2 Commonly shown, the first side plate 20 includes a side plate body 22 fixedly connected to the pipe body 10 , the edge of the side plate body 22 is provided with two grooves 222 , and the two grooves 222 are connected to the center of the first side plate 20 Symmetrically and equidistantly distributed on the side plate body 22, each groove 222 is respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com