Biological fermentation all-in-one machine

A bio-fermentation, all-in-one technology, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biomass post-processing, etc. Fast and other problems, to achieve the effect of fast assembly adjustment, increase product output, and reduce deflection probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The above content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. However, it should not be understood that the scope of the above-mentioned subject of the present invention is limited to the following examples. All technologies implemented based on the above content of the present invention belong to the scope of the present invention.

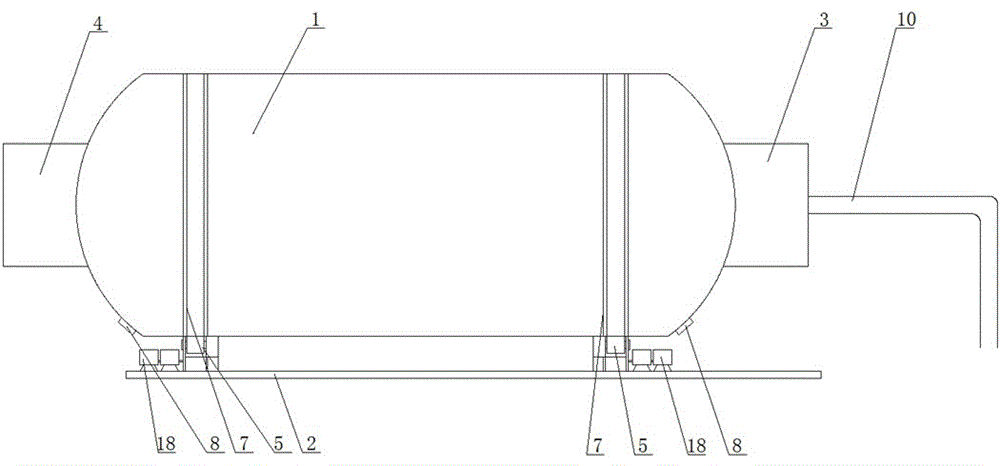

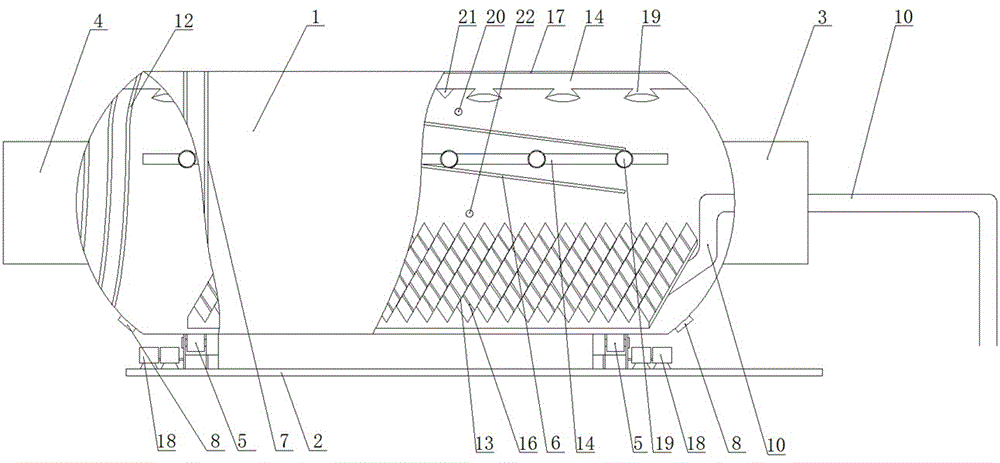

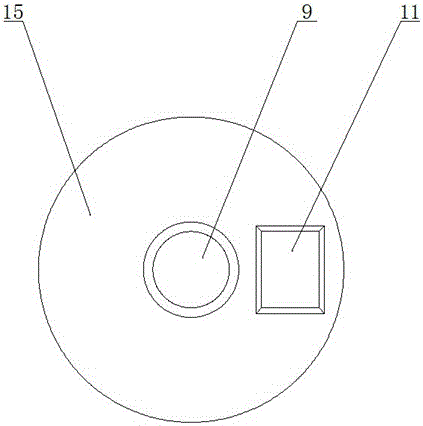

[0035] Examples. A bio-fermentation integrated machine, comprising a cylindrical drum 1 placed horizontally, made of stainless steel such as chromium, nickel, titanium, etc. The two ends are curved structures connected with the side of the cylindrical drum 1 smoothly, and one end is provided with a feed inlet 3. The other end is provided with a discharge port 4. Both the feed port 3 and the discharge port 4 are provided with an end cover 15 that can be opened and closed. The end cover 15 of the feed port 3 is provided with an observation window 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com