Device for distributing granular material onto a continuously travelling support and bunker for granular material

A bulk material and silo technology, which is applied in the pretreatment of molding materials, household components, household appliances, etc., can solve the problems of high investment cost and high cost, achieve high production capacity, reduce the structure height, and save manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

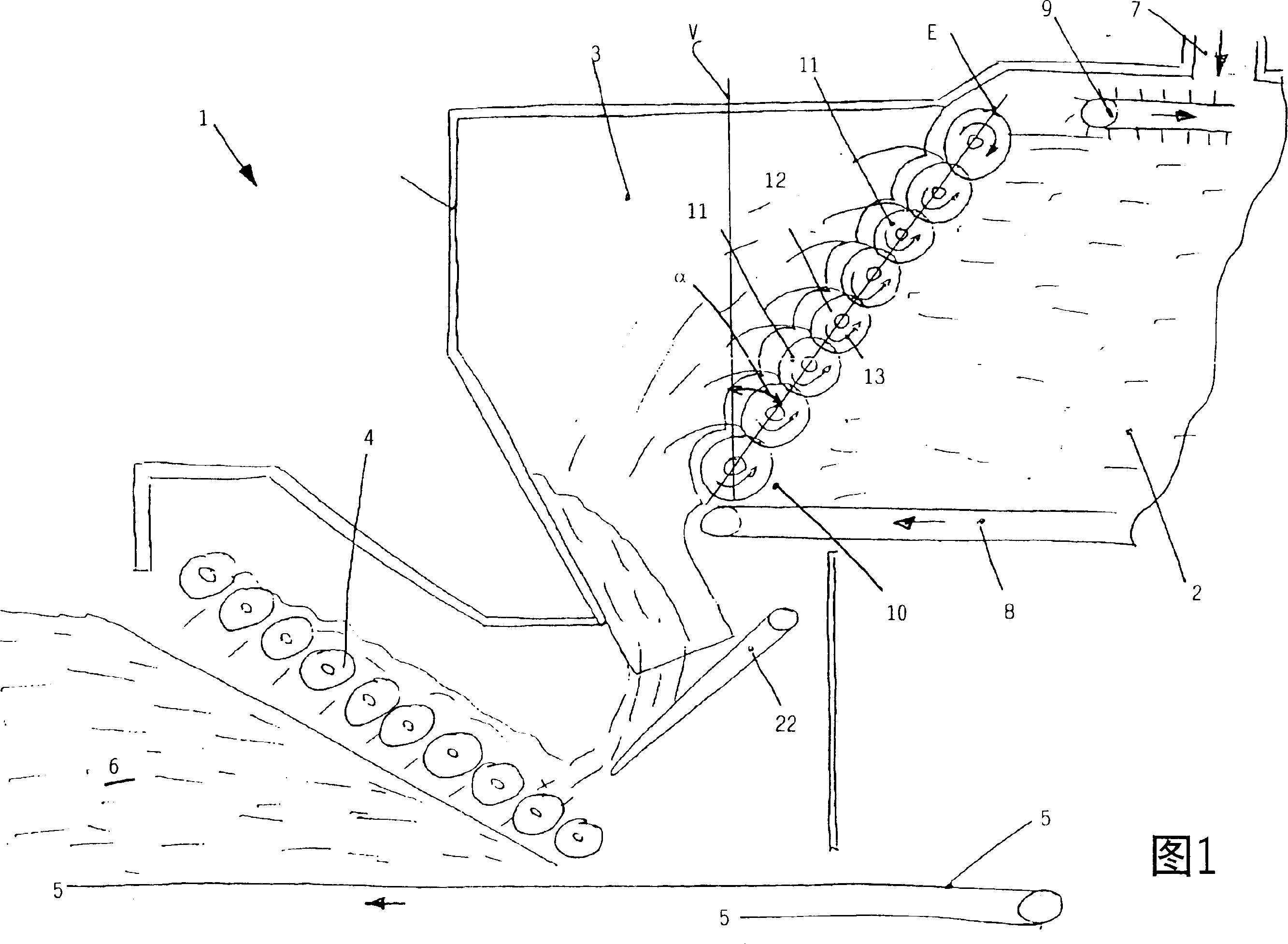

[0031] Figure 1 shows a schematic view of a spreading station 1, which is provided with a dosing bin 2, a stabilizing grid 3, a spreading roller device 4 and a forming belt 5 formed from loose bulk material Material fiber layers (Material vlies) 6 are sprinkled on the forming belt.

[0032] Lignocellulosic and / or cellulose-containing particles of different particle sizes, such as fibers, wood chips and the like, are considered primarily as dispersed bulk material. For the production of fiberboards, wood fibers provided with adhesives are usually used.

[0033] The glued wood fibers are conveyed to the feed area 7 of the metering silo 2 via a screw conveyor, not shown. Through a rotating process, the screw conveyor distributes the fibers over the entire width of the silo. A bottom conveyor belt 8 is provided at the bottom of the silo, on which wood fibers are deposited and the entire fiber layer deposited is slowly transported to an outfeed area 10 . In order to deliver as u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com