Conical trajectory vibrating screen

A vibrating sieve and trajectory technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of excessive vibration intensity, etc., and achieve the effect of improving efficiency, improving stability and working stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

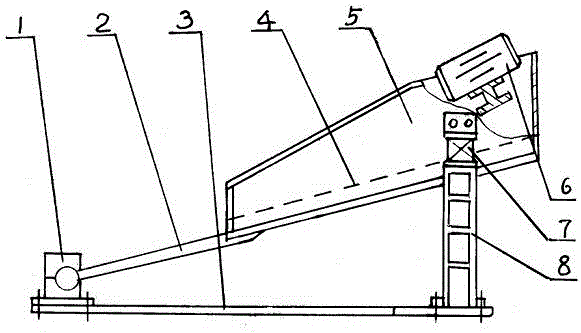

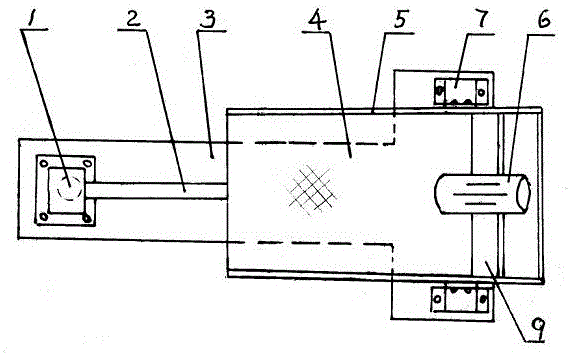

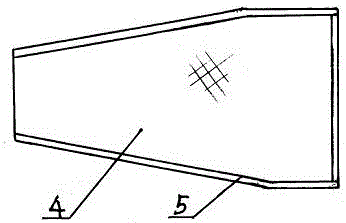

[0009] An embodiment of the present invention is described below with reference to the accompanying drawings, which mainly consists of a screen box, a screen surface, a vibrator, a vibration-damping support device and a base. The vibrator 6 is installed on the feed end of the screen box 5, and the feed end of the screen box 5 is connected to the base 3 through the vibration-damping support device 7; the discharge end of the screen box 5 is connected to the spherical support fixed on the base through the elastic rod 2 Seat 1 is hinged, and the length of elastic rod 2 is less than the length of screen box. The vibrator 6 is a uniaxial vibrator, which is installed on the side plate of the screen box 5 by the vibrator mounting beam 9, and the centerline of the vibration axis of the uniaxial vibrator passes through the center of the spherical bearing 1 on the base. The connection between the spherical bearing 1 and the elastic rod 2 is a rolling connection through a rolling bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com