Tobacco leaf cut-tobacco-making pretreating process and production line

A pretreatment and production line technology, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of difficult to achieve automatic real-time online processing, difficult to configure processing equipment, unsatisfactory insecticidal effect, etc., and achieve loosening and insecticidal effect. Good, improve the quality of pretreatment processing, the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

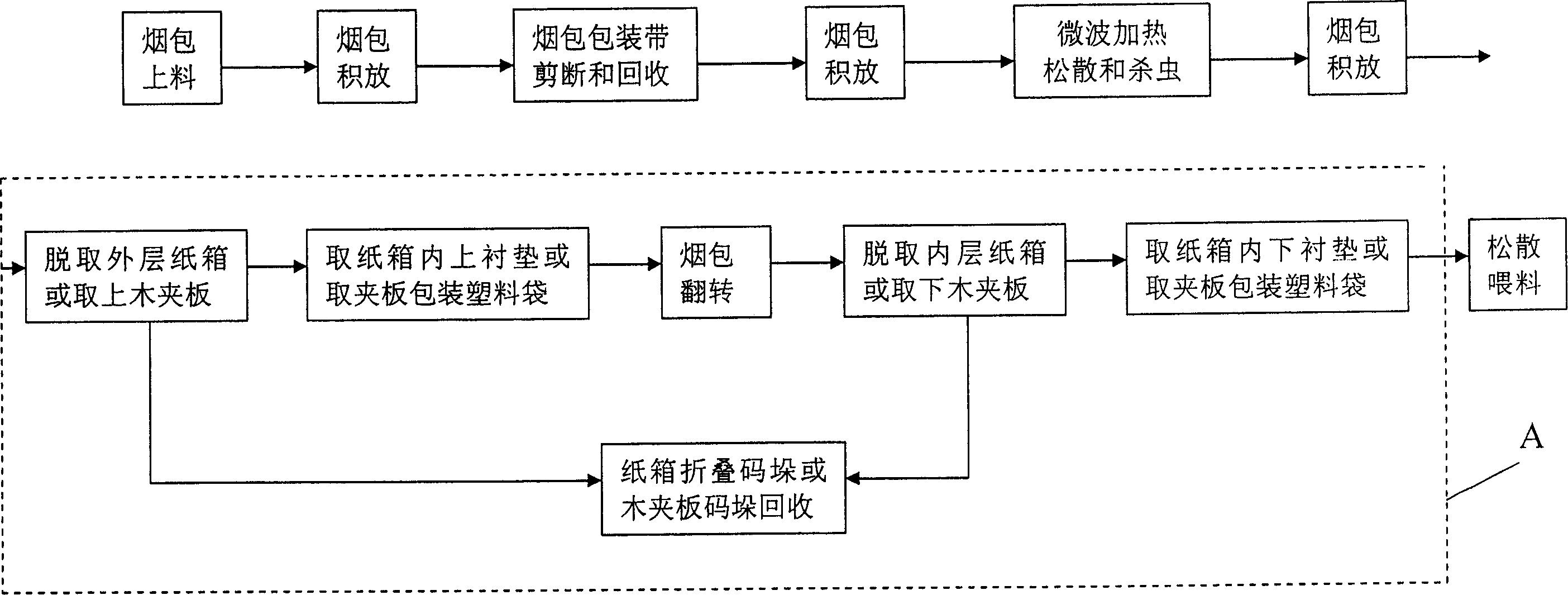

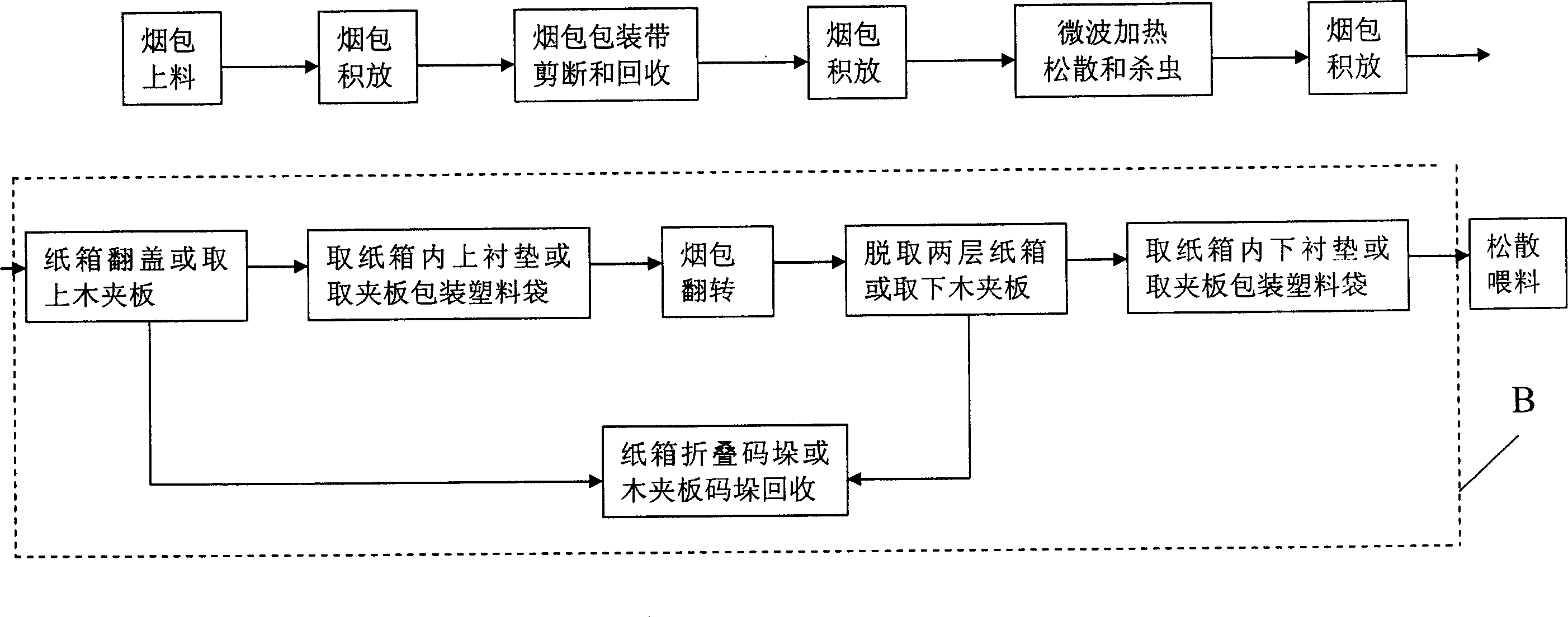

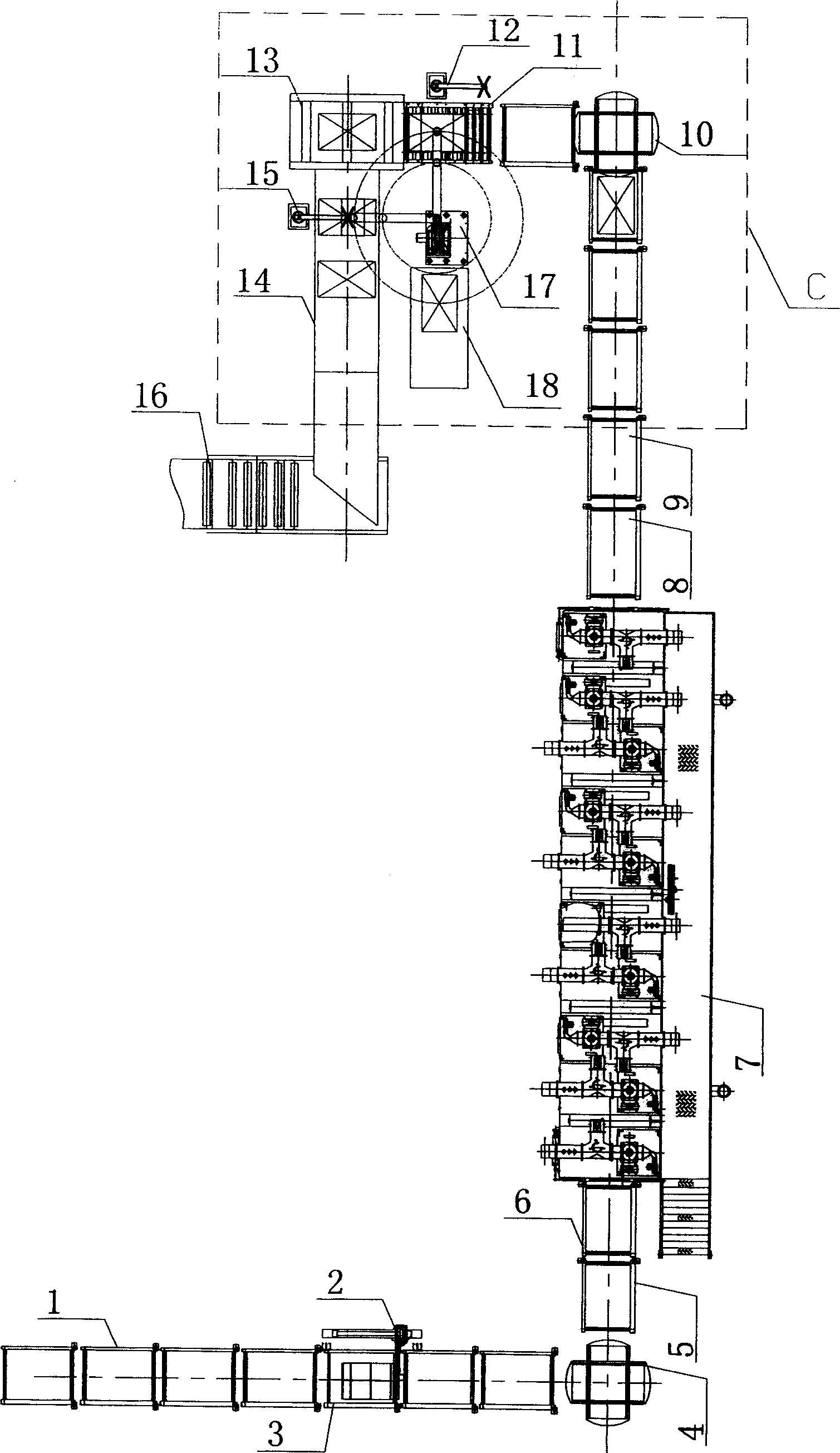

[0039] like figure 1 , image 3 Shown, technique of the present invention mainly comprises following operation:

[0040] ①. Cigarette bale loading: the leaf tobacco bale is sent from the cigarette bale warehouse to the silk pretreatment line by the conveying device;

[0041] ②, Cigarette package accumulation: that is, use the accumulation type conveying device to cache and transport cigarette packages;

[0042] ③. Cutting and recycling of cigarette packaging tapes: Unpacking on the conveying line, that is, cutting carton cigarette packs or wooden plywood cigarette packaging tapes and recycling;

[0043] ④ Accumulation of cigarette packs after unpacking: the storage and delivery of cigarette packs is carried out by the accumulation type conveying device;

[0044] ⑤. Microwave heating and loosening and killing insects: use microwave heating device to microwave the cigarette packs to realize softening and loosening of the cigarette packs, and kill all kinds of tobacco insects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com