Quick-drying solvent-free polyurethane adhesive and preparation method thereof

A polyurethane adhesive and solvent-free technology, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problem of long residual time of primary aromatic amine, increased friction coefficient of PE film, and many white spots on product appearance and other problems, to achieve the effect of large-scale industrial production and popularization and application, small strength attenuation, and excellent cooking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

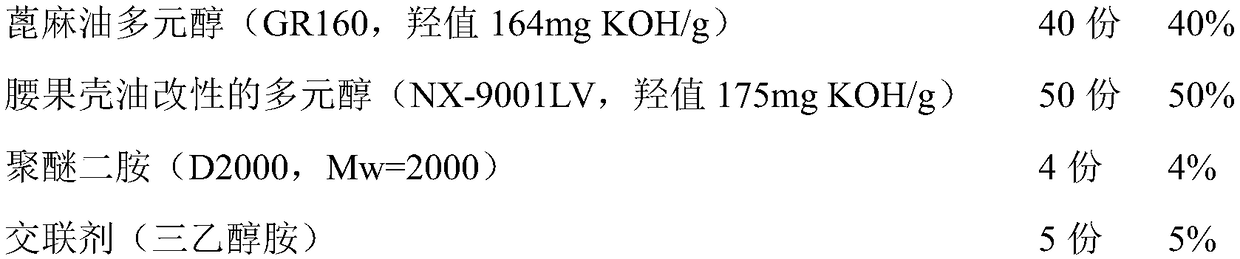

Examples

Embodiment 1

[0059] The synthesis of embodiment 1 A-1

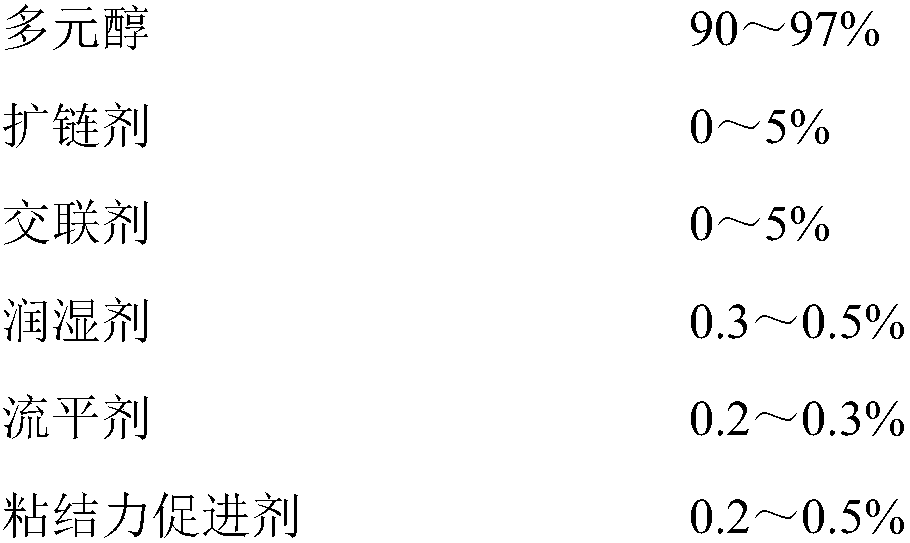

[0060] Weight percent:

[0061] Polyether polyol (polyoxypropylene diol, hydroxyl value 112mg KOH / g) 30 parts 30%

[0062] Castor oil polyol (GR160, hydroxyl value 164mg KOH / g) 15 parts 15%

[0063] Polyisocyanate (MDI) 55 parts 55%

[0064] React the above-mentioned raw materials at 70°C for 4 hours to obtain the isocyanate-terminated prepolymer, which is component A; hereinafter referred to as A-1.

Embodiment 2

[0065] The synthesis of embodiment 2 A-2

[0066] Weight percent:

[0067] Polyester diol (polyester neopentyl adipate, hydroxyl value 112mg KOH / g) 10 parts 10%

[0068] Polyether polyol (polyoxypropylene diol, hydroxyl value 56mg KOH / g) 30 parts 30%

[0069] Polyisocyanate (MDI) 60 parts 60%

[0070] React each component at 75°C for 3 hours to obtain the isocyanate-terminated prepolymer, which is component A; hereinafter referred to as A-2.

Embodiment 3

[0071] The synthesis of embodiment 3 A-3

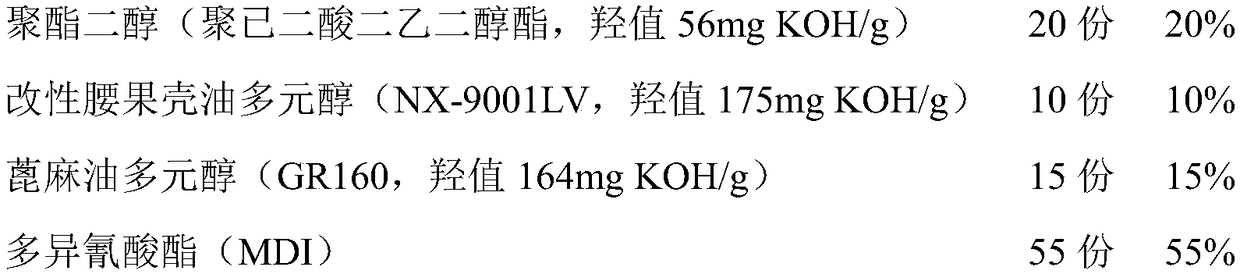

[0072] Weight percent:

[0073]

[0074] React the above-mentioned raw materials at 90°C for 2 hours to obtain the isocyanate-terminated prepolymer, which is component A; hereinafter referred to as A-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com