Preparation method and application of fast cooked anti-aging instant food grain rice

An anti-aging and miscellaneous grain technology, applied in the fields of application, food preparation, food science, etc., can solve problems such as no effective technical solutions, achieve good taste and quality, avoid quality decline, and prevent aging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

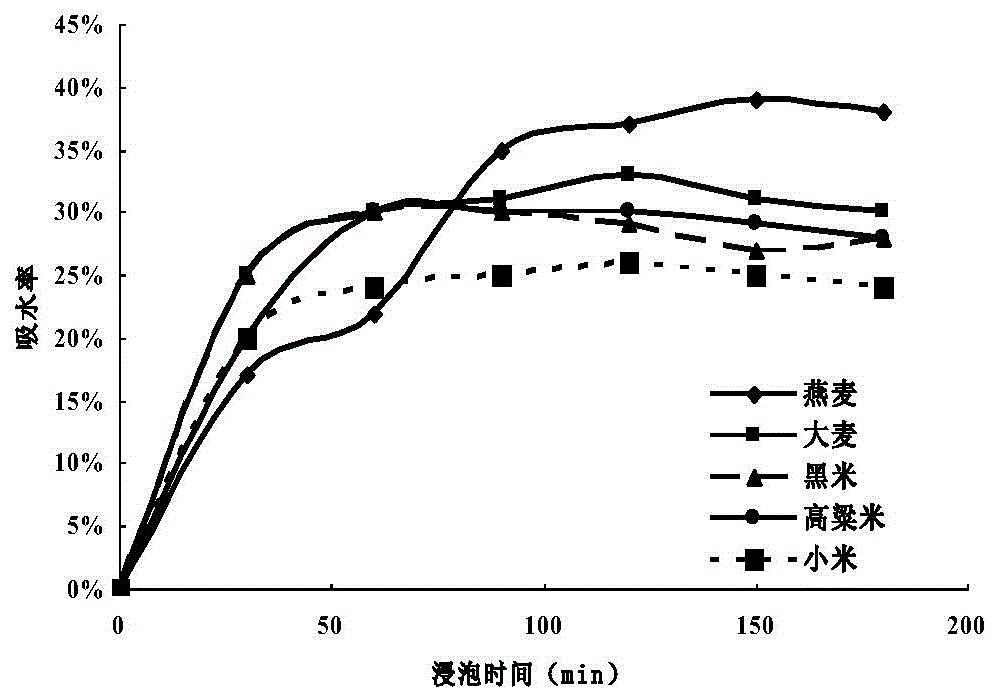

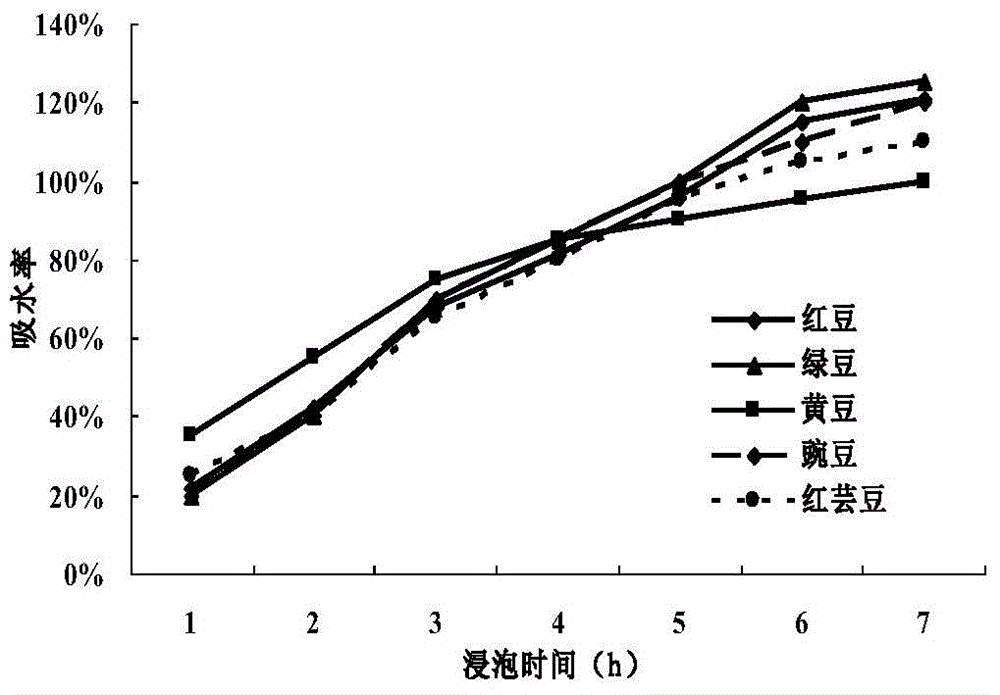

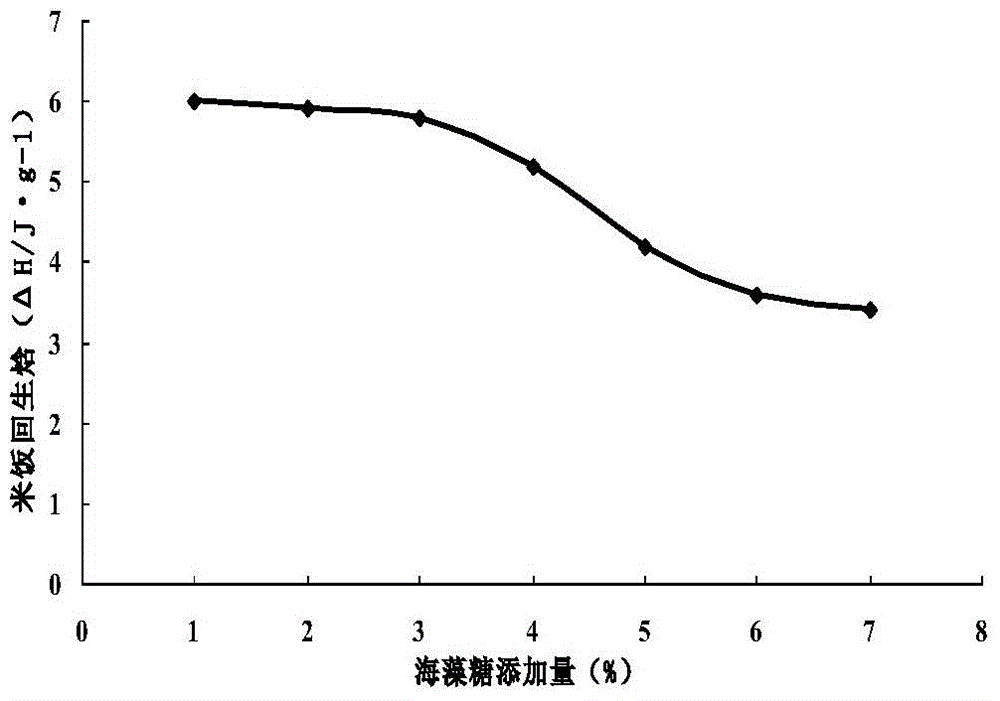

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for producing instant rice (patent publication number 103844202A), which belongs to the technical field of food processing. Ordinary rice is selected as raw material, after soaking and steaming, adding ethanol aqueous solution to separate it, after filtering, continuing to stew the rice, tempering, and using infrared and ultrasonic synergistic drying, the prepared instant rice has low water activity, good rehydration performance and storage property . The main process steps are as follows, rice screening and elutriation: choose rice without sand impurities as raw material, and wash it with tap water 2-3 times to remove dust and rice bran and other sundries; soak rice and add 1.2-1.4 Double the amount of tap water, soak at 35-45°C for 20-30 minutes; steam and disperse the rice: cook the soaked rice for 20-25 minutes until it is completely gelatinized, add 2 times the amount of ethanol aqueous solution to disperse, filter and stew the ric...

Embodiment 2

[0036] The making of embodiment 2 instant barley soybean meal

[0037] The pretreated japonica rice is obtained after cleaning and elutriating the japonica rice. Then barley and soybean are pretreated under the following conditions:

[0038] The selected soaking solution is a mixture of 5% trehalose and 0.3% lecithin, the weight ratio of the mixed grains to the soaking liquid is 1:3, the soaking temperature is 25°C, and the soaking time is 6 hours; after soaking, put the grains into the steamer After adding 1.2 times the mass of water, cook for 15 minutes; then carry out microwave drying, the condition is that the microwave power is 300W, and the drying time is 20 minutes. The pretreated miscellaneous grains were obtained after microwave drying.

[0039] Put the pretreated stem rice, barley and soybeans (70% of stem rice, 25% of barley, and 5% of soybean) into the soaking liquid together, and the composition of the soaking liquid is trehalose 5%, lecithin 0.3%, rice The weigh...

Embodiment 3

[0040] The making of embodiment 3 instant oatmeal red bean rice

[0041] The pretreated japonica rice is obtained after cleaning and elutriating the japonica rice. Then oats and red beans are pretreated under the following conditions:

[0042] The selected soaking solution is a mixture of 7% trehalose and 0.1% lecithin, the weight ratio of the mixed grains to the soaking liquid is 1:2, the soaking temperature is 20°C, and the soaking time is 1h; after soaking, put the grains into the steamer After adding 1.5 times the mass of water, cook for 30 minutes; then carry out microwave drying, the condition is that the microwave power is 500W, and the drying time is 10 minutes. The pretreated miscellaneous grains were obtained after microwave drying.

[0043] Put the cleaned and washed stem rice and pretreated oats and red beans (70% of stem rice, 25% of oats, and 5% of red beans) into the soaking liquid together, and the composition of the soaking liquid is 7% trehalose , lecithin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com