Adhesive, laminated film using the same and polyol composition for adhesive

A polyol composition and adhesive technology, applied in adhesives, household components, adhesive types, etc., can solve the problems of not being able to obtain actual packaging, and achieve excellent curability, improved appearance, and better texture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0087] Production example 1 [synthesis of polyisocyanate (A-1)]

[0088] 36 parts of 4,4-diphenylmethane diisocyanate and 19 parts of 2,4'-diphenylmethane diisocyanate were put into a reaction vessel in a flask equipped with a stirrer, a thermometer, and a nitrogen gas introduction tube, and stirred under nitrogen gas , heated to 60°C. Add 11 parts of polypropylene glycol (hereinafter abbreviated as "PPG") with a number average molecular weight of 400, 22 parts of PPG with a number average molecular weight of 1000, and 11 parts of PPG with a number average molecular weight of 2000 in several drops, and stir for 5 to 6 hours to make the amino group The formic esterification reaction ends. The NCO group content rate of the obtained polyisocyanate was 13.5%, and the melt viscosity at 40 degreeC was 1500 mPa.s. Hereinafter, this polyisocyanate is abbreviated as "A-1".

Embodiment 1~21 and comparative example 1~9

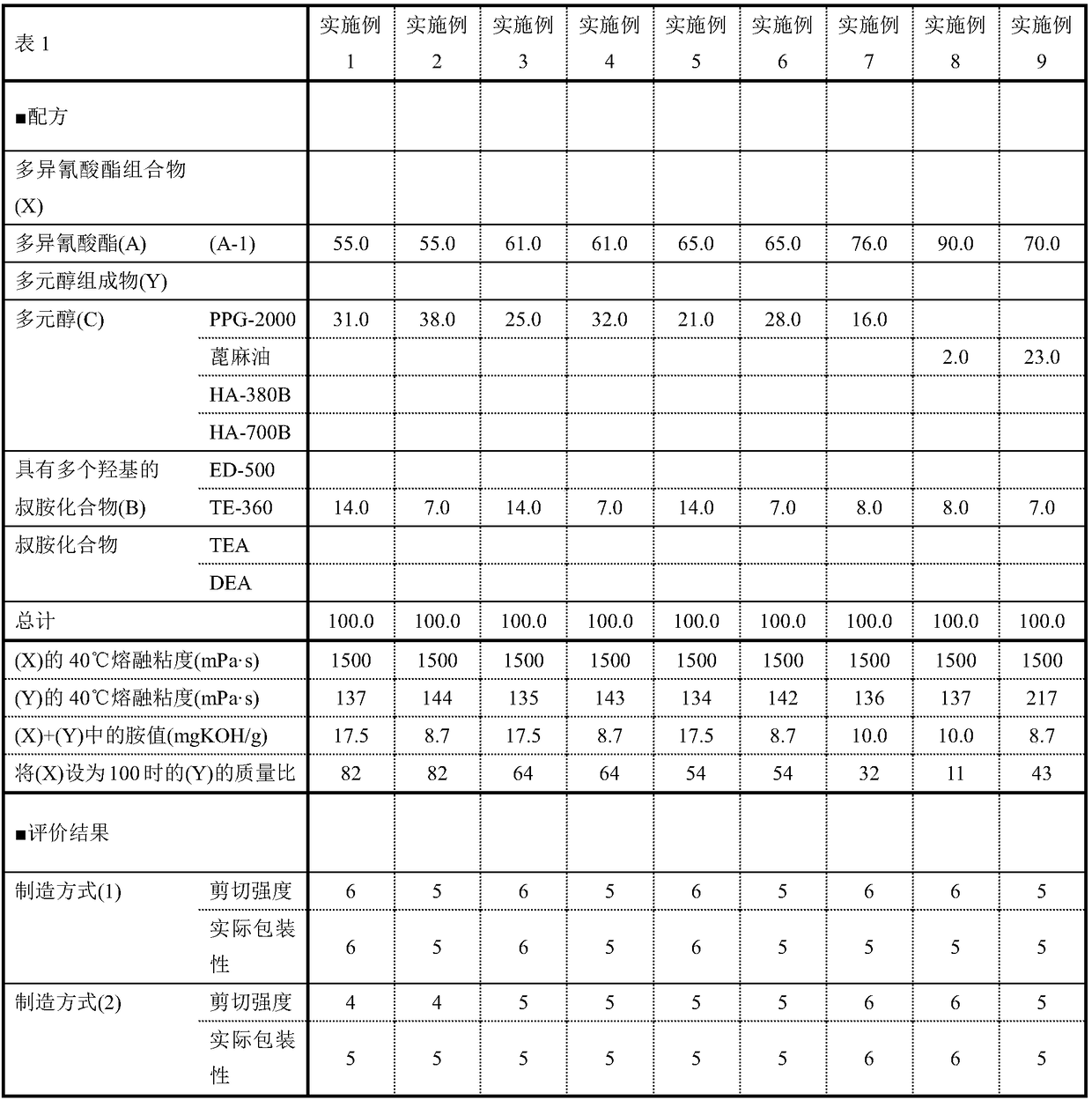

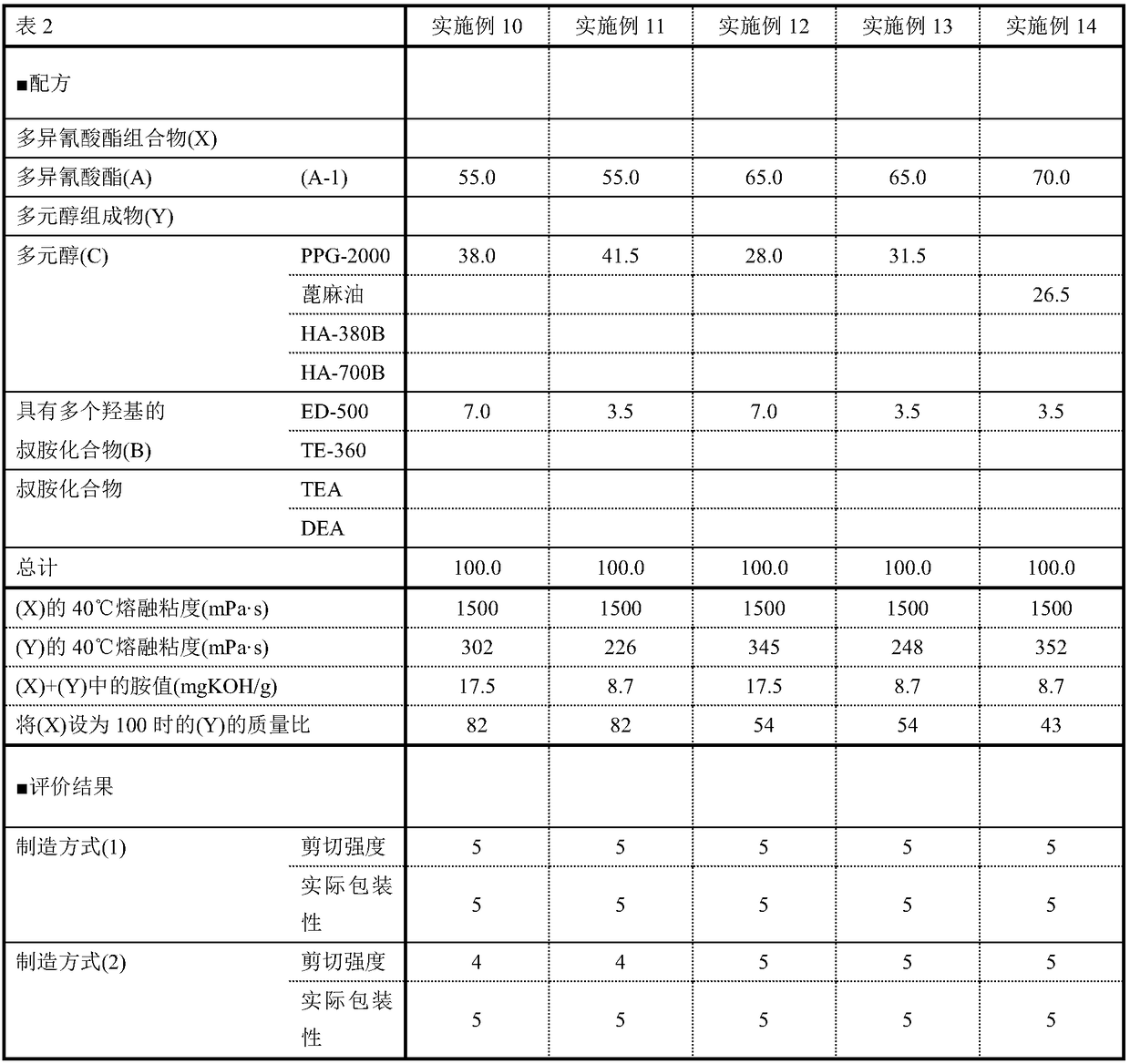

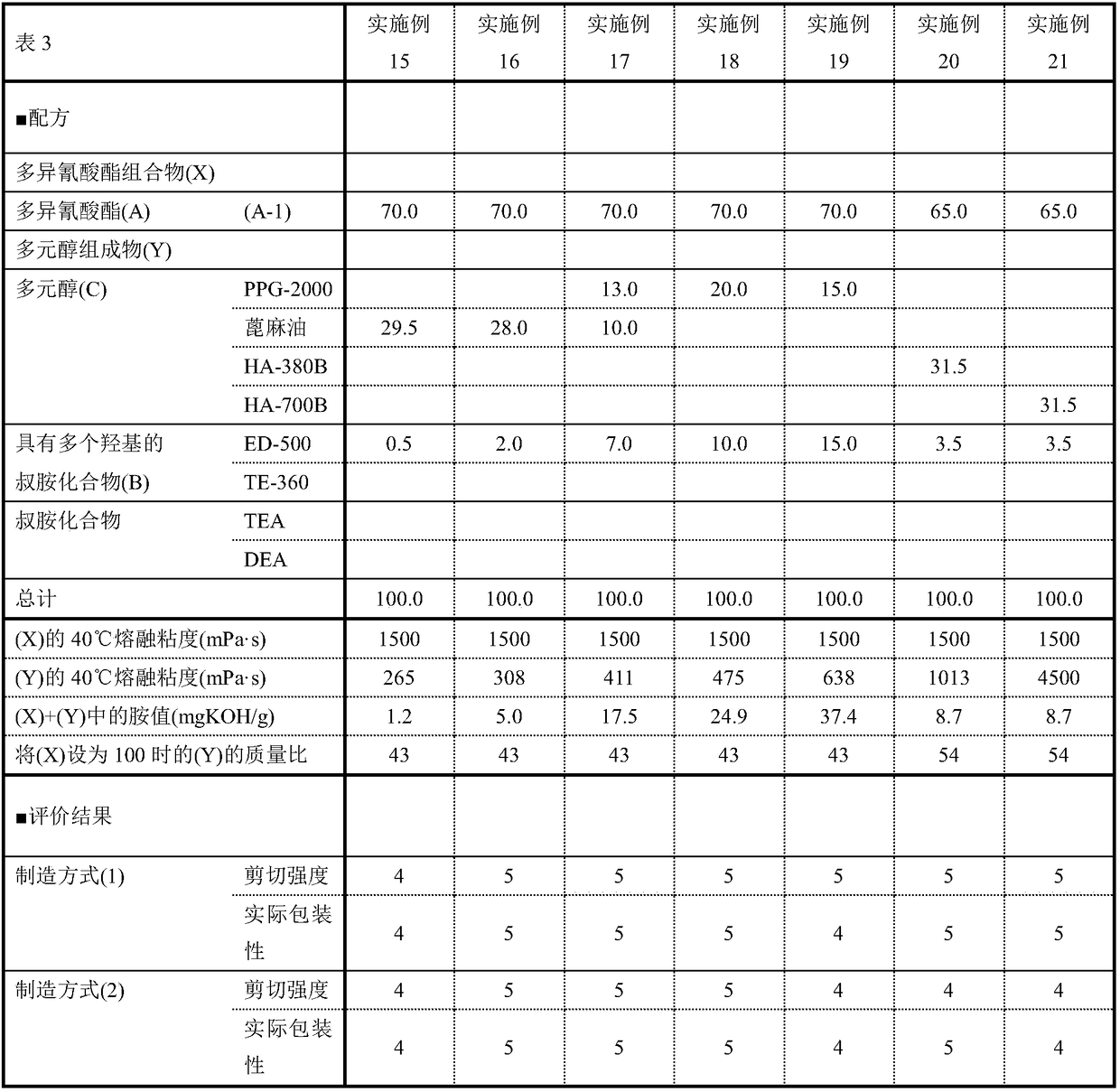

[0090] Adhesives were prepared according to the formulations in Table 1, Table 2, and Table 3, and the following various evaluations were performed. The results are shown in Tables 1-3.

[0091] (Manufacturing method of film for flexible packaging)

[0092] As a manufacturing method of the film for flexible packaging, it carries out by manufacturing method (1) and manufacturing method (2).

[0093] (manufacturing method 1)

[0094] After preparing an adhesive from the polyisocyanate composition (X) and polyol composition (Y) according to the formulations described in Tables 1 to 5, the adhesive was coated on the film A so that the coating amount became 2.0 g / m 2 Left and right, the coated surface of the film A was bonded to the film B using a laminator to prepare a laminated film for shear strength measurement.

[0095] (manufacturing method 2)

[0096] Prepare polyisocyanate composition (X) and polyol composition (Y) respectively according to the formulations described ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com