Grease composition, composite grease composition, product and preparation method thereof

A kind of oil and fat composition, the technology of the composition, applied in the direction of production/processing of edible oil/fat, etc., can solve the problems of reducing production efficiency, prolonging the curing step of plastic oil, inconvenient industrial production of plastic oil and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0171] Preparation method of plastic oil product

[0172] The present invention also provides a method for preparing the plastic oil product of the present invention, the method comprising:

[0173] (i) provide the grease composition of the present invention;

[0174] (ii) The oil composition is subjected to a post-processing step including an aging step to obtain the plastic oil product.

[0175] In a specific embodiment of the present invention,

[0176] In the step (ii), the curing time is: the curing time is between 10 minutes and 2 days at 10-35 degrees.

[0177] In a specific embodiment of the present invention,

[0178] In the step (ii), the curing time is: the curing time is between 10 minutes and 36 hours at 10-35 degrees.

[0179] Of course, the upper limit of the aging time in the present invention may be higher, and may be, for example, 10 minutes to 3 days. But the advantage of the present invention is that it can save curing time without affecting other perf...

Embodiment 1-1、1-2 and 1-3

[0187] (2) Explanation on the second MCT: IV: 0.1, C8 55%, C10 44%, other fatty acids 1%. Purchased from Yihai (Lianyungang) Oil Chemical Industry Co., Ltd. (see Examples 1-4, 1-5 and 1-6)

[0188] (3) Notes on canola oil and fish oil:

[0189] Extremely hydrogenated high erucic acid rapeseed oil iodine value 0.5gI 2 / 100g, deep sea fish oil iodine value 202gI 2 / 100g.

[0190]

[0191] test methods

[0192] (1) Determination of total fatty acid composition, triglyceride composition and solid fat content is as shown in the description part.

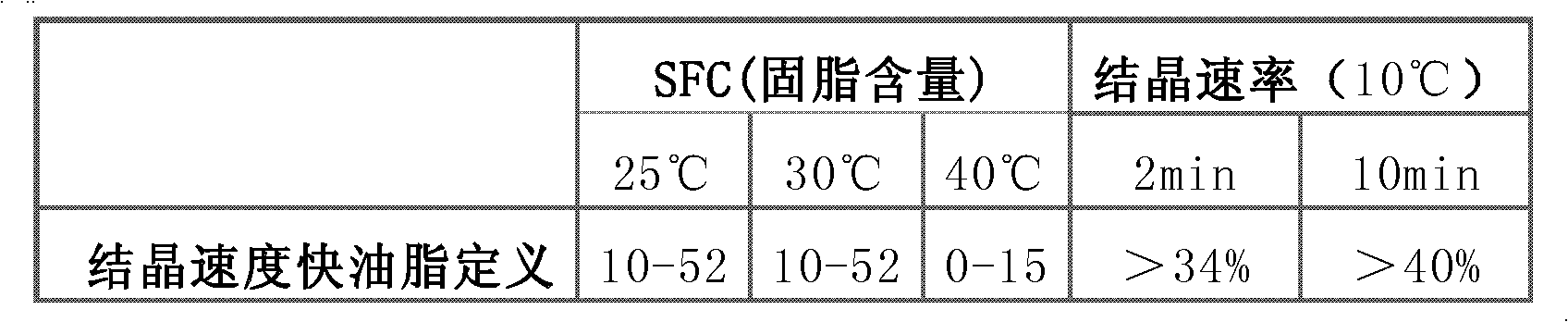

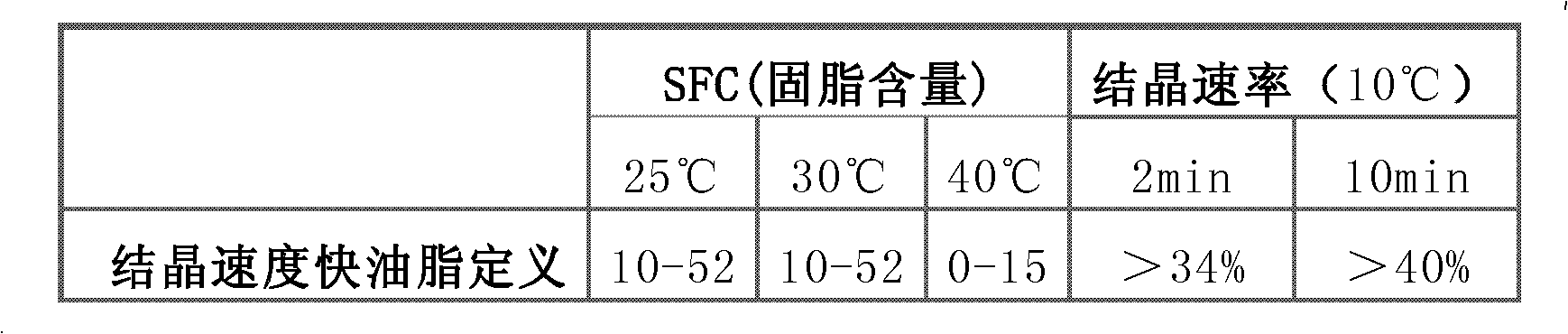

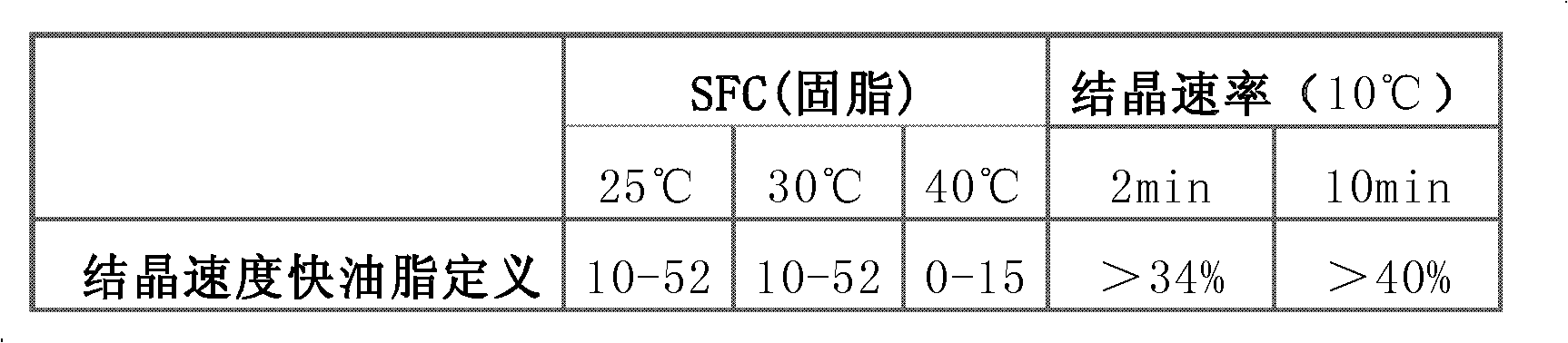

[0193] (2) Sandwich oil solid fat and fast crystallization speed (the detection method of crystallization speed is: put the oil at 60 degrees for half an hour, then put it at 10 degrees, put it in the fat solidifying instrument for a specified time to measure a data, and divide this data Solid fat at 10 degrees to obtain crystallization rate) as shown below.

[0194]

Embodiment 1-1

[0196] MCT [IV: 0, C8 60%, C10 40%, purchased from Corning Chemical (China) Co., Ltd.] and extremely hydrogenated palm oil [IV: 0.5, purchased from Kerry Special Oils (Shanghai) Co., Ltd.] = 33: 67 is formed by transesterification, refining, quenching and kneading.

[0197] Vacuum dry the mixed oil and fat raw materials (stir in vacuum, heat up to 105°C, keep for 15min); then add 0.8% catalyst sodium methoxide, react at 100°C for 45min; then add 8% citric acid aqueous solution, stir for 30min, The reaction was terminated, and then the reactant was washed with water until the pH was 7, and then centrifuged to obtain transesterified oil.

[0198] Then carry out oil refining operation on the obtained transesterified oil: vacuumize and heat the transesterified oil to 105°C, keep it for 30min, dehydrate and dry; then add 2% activated clay, keep it at 110°C for 30min for decolorization, add diatomaceous earth filter to obtain transesterified oil. Finally, vacuumize at 240°C and de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com