Polyethylene terephthalate (PET) polyester composition not containing antimony and cobalt elements

A technology of polyethylene terephthalate and composition, which is applied in the field of polyethylene terephthalate polyester composition, can solve the problems of reducing the transparency of PET finished products and promoting the thermal cracking of PET polyester, etc. Achieve the effect of good hue, low regeneration amount and low production cost

Inactive Publication Date: 2011-04-06

NANYA PLASTICS CORP

View PDF17 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Even in the polymerization process of PET polyester, it is difficult to improve the yellowish hue by adding dyes, so cobalt acetate is usually added to obtain a better hue; but cobalt metal will promote thermal cracking of PET polyester during processing , and will reduce the transparency of PET finished products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

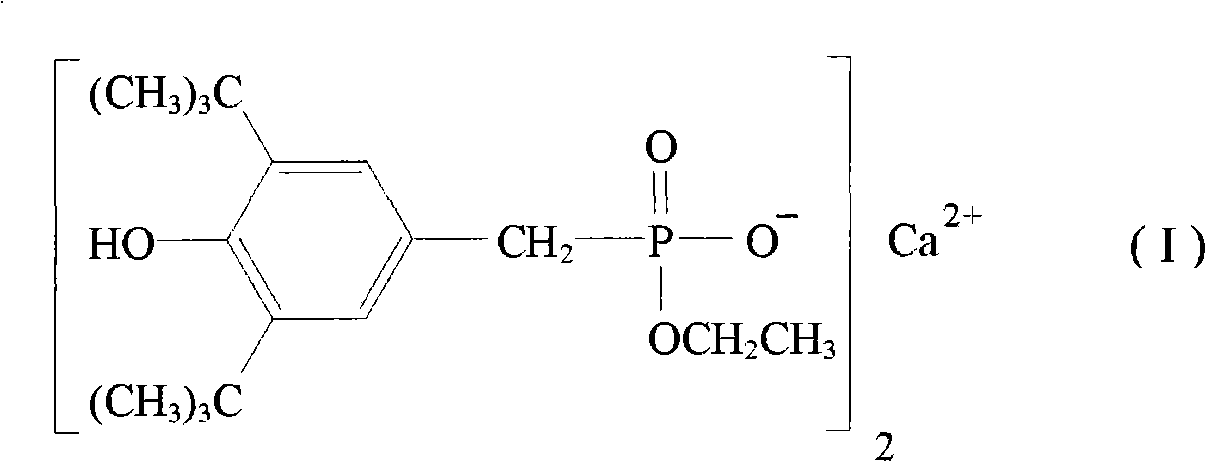

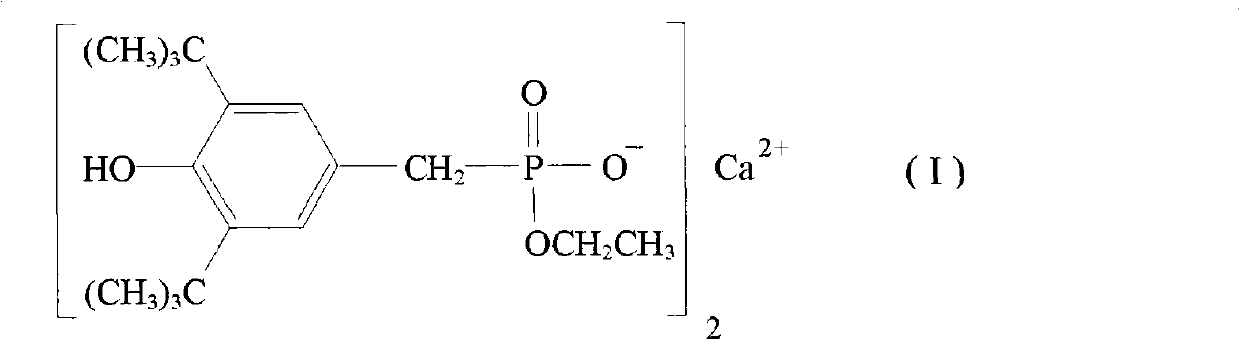

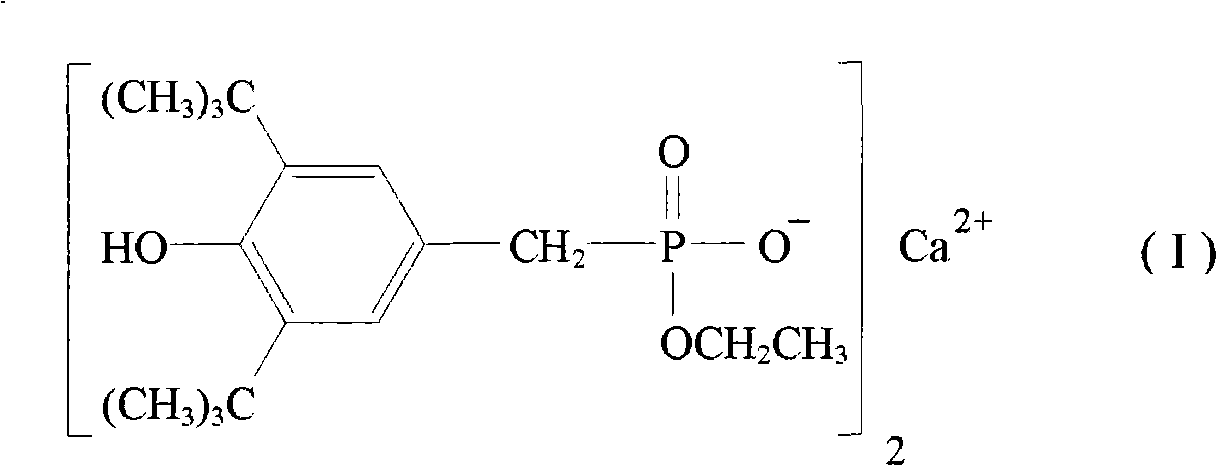

The invention discloses a polyethylene terephthalate (PET) polyester composition, which has the advantages of high solid polymerization reaction speed and relatively low regeneration amounts of aldehyde and cyclic oligomer during processing. In a polymerization process, a titanium element-containing compound is taken as a condensation polymerization catalyst, and a phosphorus element-containing stabilizing agent and an organic dye are added to avoid a yellow phase of polyester; and a phosphorus and calcium-containing compound shown as a structural formula (I) is added to increase the solid polymerization reaction speed of PET prepolymer and enhance the processing quality of a synthesized PET polyester composition; and when the polyester composition is used for processing and manufacturing a bottle mold, the regeneration amounts of the aldehyde and the cyclic oligomer are relatively low.

Description

technical field The invention relates to a polyethylene terephthalate (PET) polyester composition without adding antimony and cobalt elements, especially a PET polyester composition containing titanium elements, phosphorus elements, calcium elements and organic dyes It has the advantages of fast solid-state polymerization reaction rate and low regeneration of acetaldehyde and cyclic oligomers during processing. Background technique The known synthesis process of polyethylene terephthalate (PET) polyester usually uses antimony (Sb) catalyst as polycondensation catalyst, and uses pure terephthalic acid (PTA) and ethylene glycol (EG) as Raw materials, after the first stage of direct esterification and the second stage of polycondensation reaction (polycondensation), then add antimony (Sb) catalyst in the second stage of polycondensation reaction, or as required, after completing the second stage of polycondensation The reaction is followed by additional solid-state polymerizat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L67/02C08G63/183C08G63/85C08K3/22C08K3/32C08K5/5333

Inventor 简日春

Owner NANYA PLASTICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com