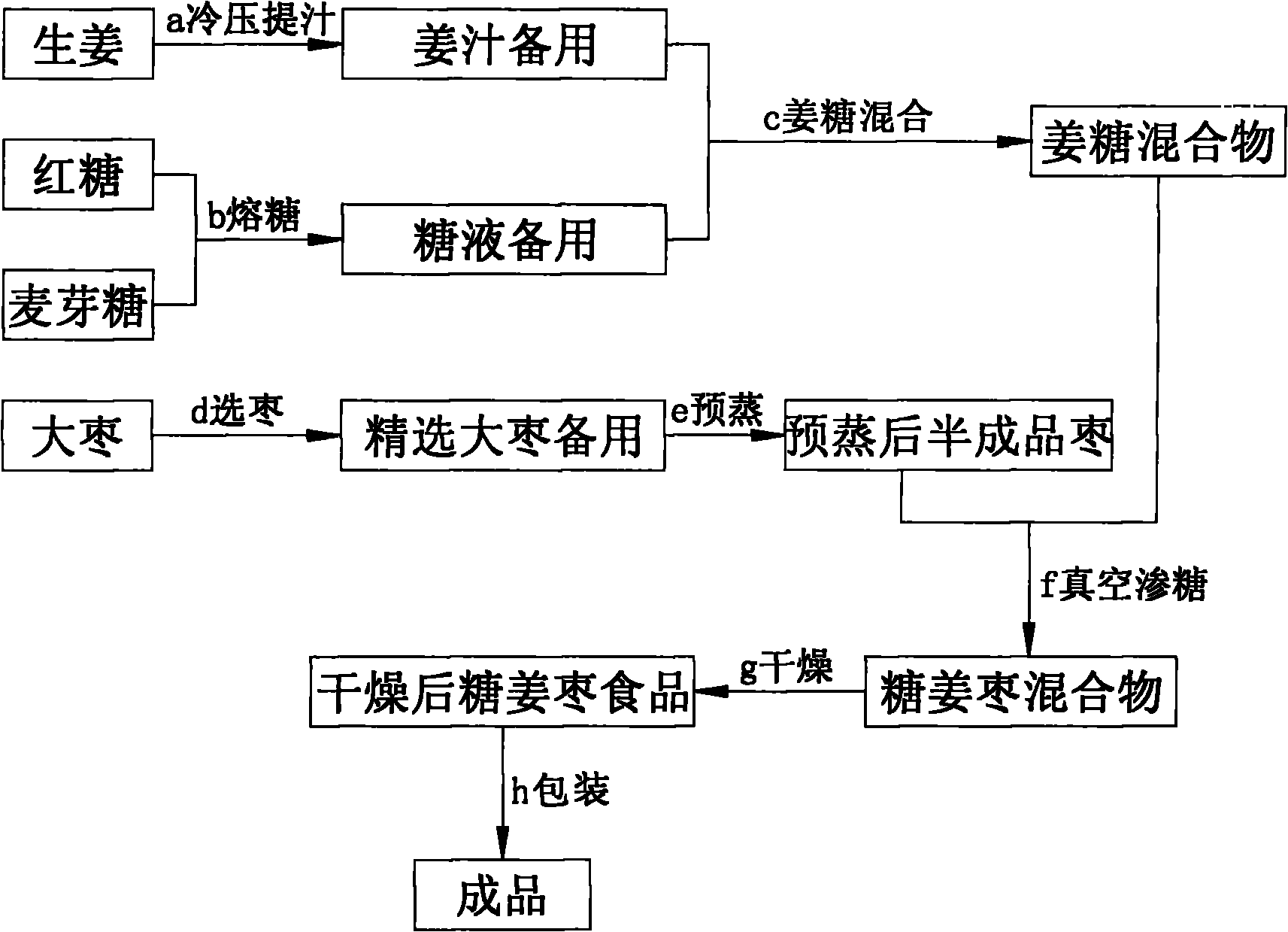

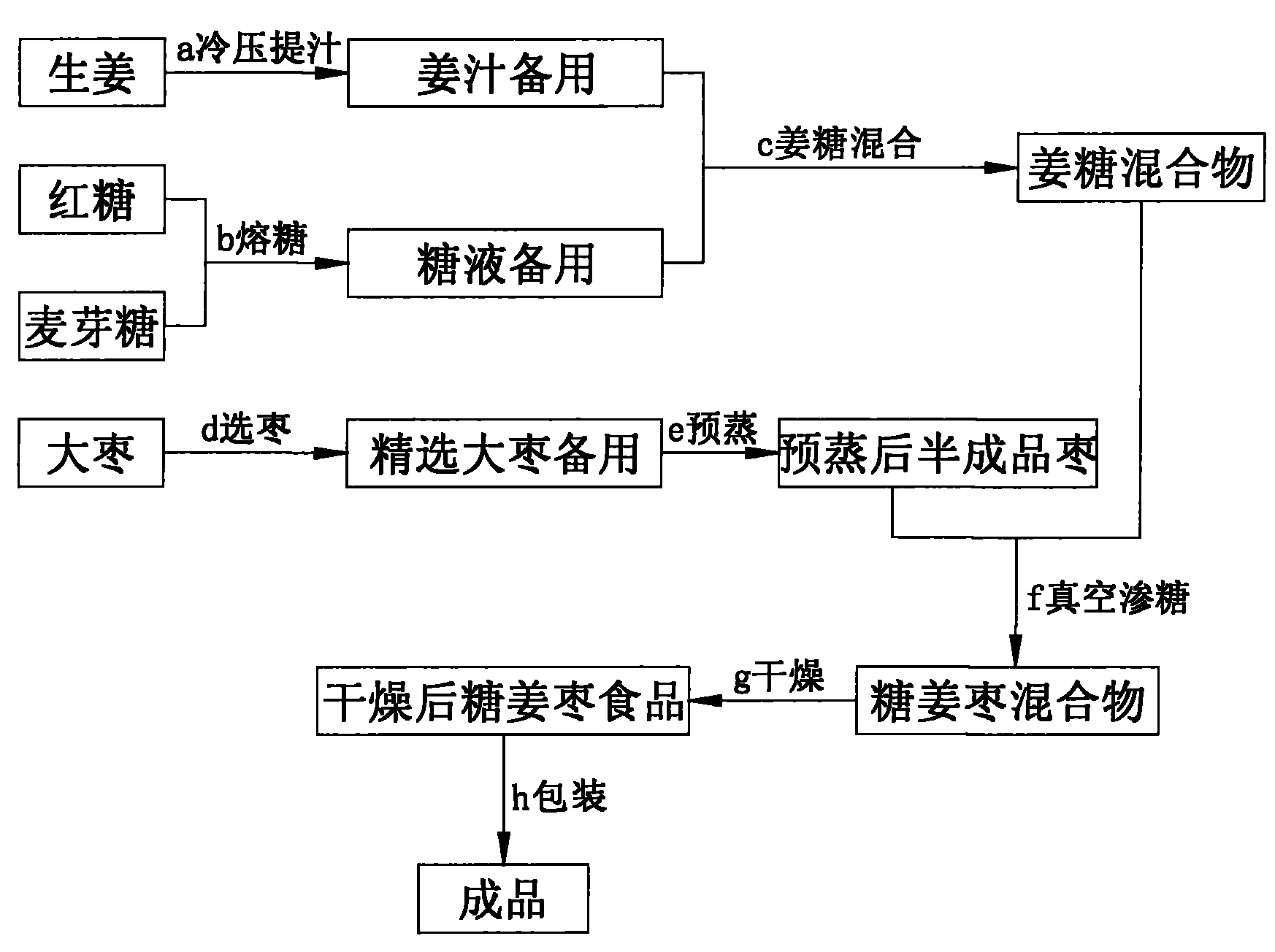

Preparation process of brown sugar, ginger and jujube food

A technology for food preparation, brown sugar ginger jujube, applied in food preparation, confectionery industry, confectionery and other directions, can solve the problems of inconvenient carrying, transportation and storage of liquid preparations, unfavorable health, damage, etc. The effect of product quality change and shortening of sugar oozing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1 (raw material parts by weight)

[0078] 25 parts of brown sugar

[0079] Maltose 15 parts

[0080] 10 servings of ginger

[0081] 30 servings of jujube

[0082] 20 parts of water.

Embodiment 2

[0083] Embodiment 2 (raw material parts by weight)

[0084] 25 parts of brown sugar

[0085] Maltose 10 parts

[0086] 15 servings of ginger

[0087] 35 jujubes

[0088] 15 parts of water.

Embodiment 3

[0089] Embodiment 3 (raw material parts by weight)

[0090] 25 parts of brown sugar

[0091] Maltose 15 parts

[0092] 15 servings of ginger

[0093] 30 servings of jujube

[0094] 15 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com