Baked porcelain powder for zirconium-oxide all-ceramic crown and preparing method thereof

A technology of zirconia and ceramic powder, applied in dental preparations, pharmaceutical formulations, dental prostheses, etc., can solve the problems of poor mechanical strength, difficult to achieve, gaps, etc., and achieve good wear resistance, corrosion resistance, and biocompatibility. Excellent performance and high color accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

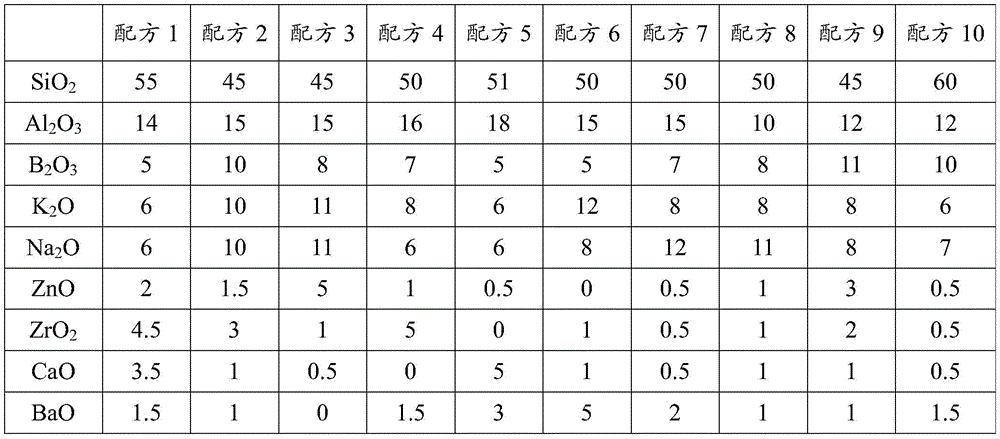

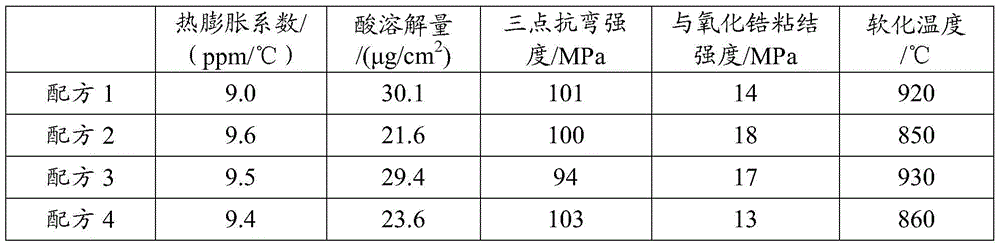

[0041] An embodiment of the porcelain powder for zirconia all-ceramic crowns of the present invention, the porcelain powder for zirconia all-ceramic crowns described in this embodiment is prepared by the following method:

[0042] (1) Ball milling: Weigh each component according to the basic bonded porcelain powder formula 1 in Table 1, then mix all the components in a ball mill jar, and ball mill with the ratio of ball: material: water = 10:0.6:0.8 2h, then take out the mixture and dry it;

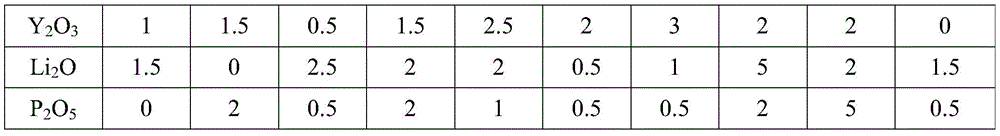

[0043] Weigh each component according to the basic body porcelain powder formula 1 in Table 2, then mix all the components in a ball mill jar, and ball mill for 2 hours with the ratio of ball:material:alcohol=8:0.8:0.5, and then mix the mixture Take out, dry;

[0044] Weigh each component according to the enamel powder formula 1 in Table 3, then mix all the components in a ball mill jar, and ball mill for 4 hours with the ratio of ball: material: acetone = 8:0.8:1, and then take out the ...

Embodiment 2

[0056] An embodiment of the porcelain powder for zirconia all-ceramic crowns of the present invention, the porcelain powder for zirconia all-ceramic crowns described in this embodiment is prepared by the following method:

[0057] (1) Ball milling: Weigh each component according to the basic bonded porcelain powder formula 2 in Table 1, then mix all the components in a ball mill jar, and ball mill with the ratio of ball: material: alcohol = 5:0.5:0.6 3h, then take out the mixture and dry it;

[0058] Weigh each component according to the basic body porcelain powder formula 2 in Table 2, then mix all the components in a ball mill jar, and ball mill for 1 hour with the ratio of ball: material: acetone = 10:0.7:0.9, and then mix the mixture Take out, dry;

[0059] Weigh each component according to the enamel powder formula 2 in Table 3, then mix all the components into a ball mill jar, and ball mill for 3 hours with the ratio of ball: material: toluene = 10:1:0.8, and then take ...

Embodiment 3

[0071] An embodiment of the porcelain powder for zirconia all-ceramic crowns of the present invention, the porcelain powder for zirconia all-ceramic crowns described in this embodiment is prepared by the following method:

[0072] (1) Ball milling: Weigh each component according to the basic bonded porcelain powder formula 3 in Table 1, then mix all the components in a ball mill jar, and ball mill with the ratio of ball: material: acetone = 8:0.8:0.5 2h, then take out the mixture and dry it;

[0073] Weigh each component according to the basic body porcelain powder formula 3 in Table 2, then mix all the components in a ball mill jar, and ball mill for 5 hours with the ratio of ball: material: toluene = 11:0.6:0.6, and then mix the mixture Take out, dry;

[0074] Weigh each component according to the enamel powder formula 3 in Table 3, then mix all the components into a ball mill jar, and ball mill for 2 hours with the ratio of ball: material: water = 8:0.7:0.6, and then take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com