Improved Stober method for preparing tio2/sio2 aerogel microsphere

An aerogel and microsphere technology, applied in the directions of silica, silica, fibrous fillers, etc., can solve the problems of complex and expensive equipment system, single aerogel property, unable to meet the multi-function, etc., and achieve infrared heat reflection. Good performance, improve production safety, good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

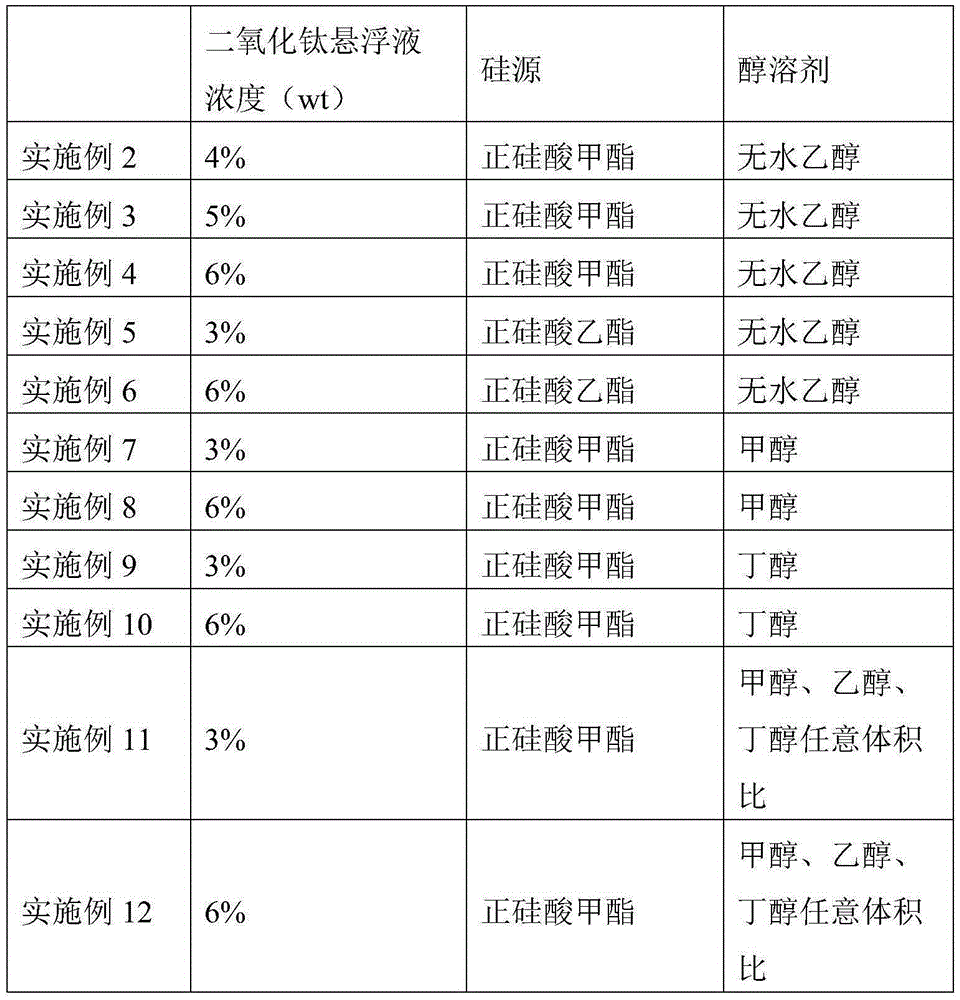

Embodiment 1

[0018] (1) Prepare titanium dioxide suspension. Measure 100ml of distilled water into a beaker, add 0.45-0.50g sodium hexametaphosphate (dispersant), stir and dissolve, then add a certain amount of rutile titanium dioxide powder with a particle size of 50nm-100nm, put the beaker into a 540w ultrasonic cell Ultrasonic dispersion in a pulverizer for 30-50 minutes to obtain a titanium dioxide suspension with a mass fraction of 3%.

[0019] The effects of local high temperature, high pressure, strong shock waves and micro jets generated by ultrasound can greatly weaken the nano interaction energy between nanoparticles, effectively prevent the agglomeration of nanoparticles and make them fully dispersed. Use rutile TiO with strong light reflection ability and refractive index 2 Doped SiO 2 Airgel can reduce the infrared extinction coefficient of the material to a certain extent and increase the TiO 2 / SiO 2 Infrared heat reflectivity of airgel.

[0020] (2) A mixed sol was pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com