Middle/high-temperature infrared emissivity testing device

A technology of infrared emissivity and testing device, which can be used in measurement devices, material analysis by optical means, instruments, etc., and can solve the problems of high cost and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

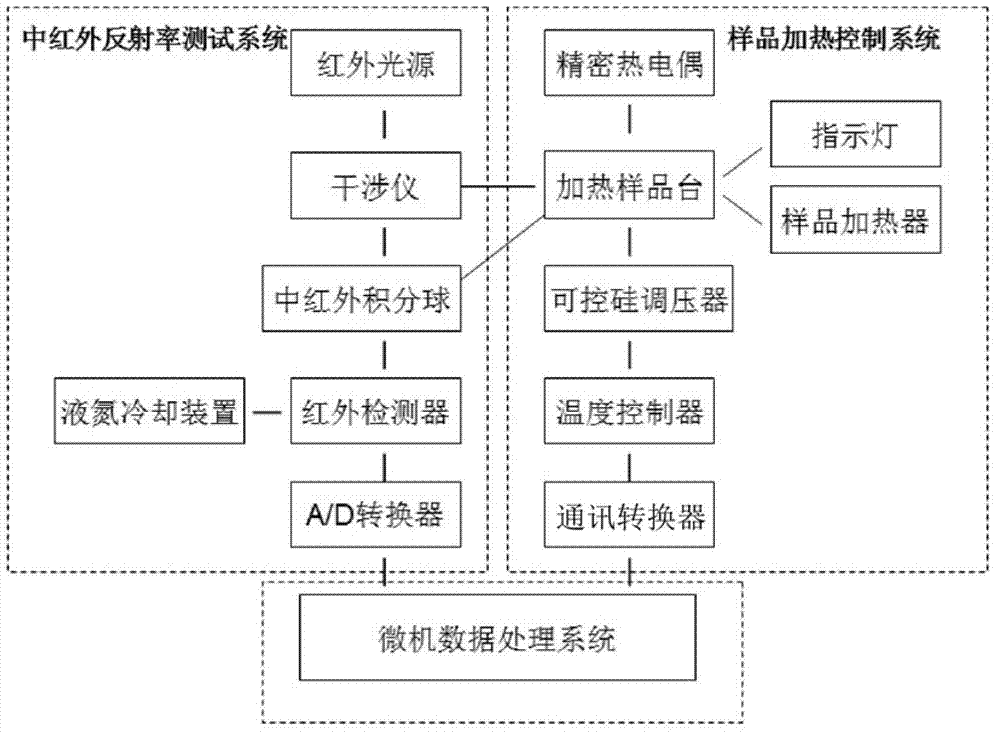

[0059] Such as figure 1 and figure 2 As shown, the medium and high temperature infrared emissivity testing device of the present invention includes a mid-infrared reflectivity testing system, a sample heating control system and a microcomputer data processing system.

[0060] The mid-infrared reflectance test system is mainly used to measure the reflectance of the sample surface, including infrared light source, interferometer, mid-infrared integrating sphere, infrared detector, A / D converter and liquid nitrogen cooling device for cooling the infrared detector .

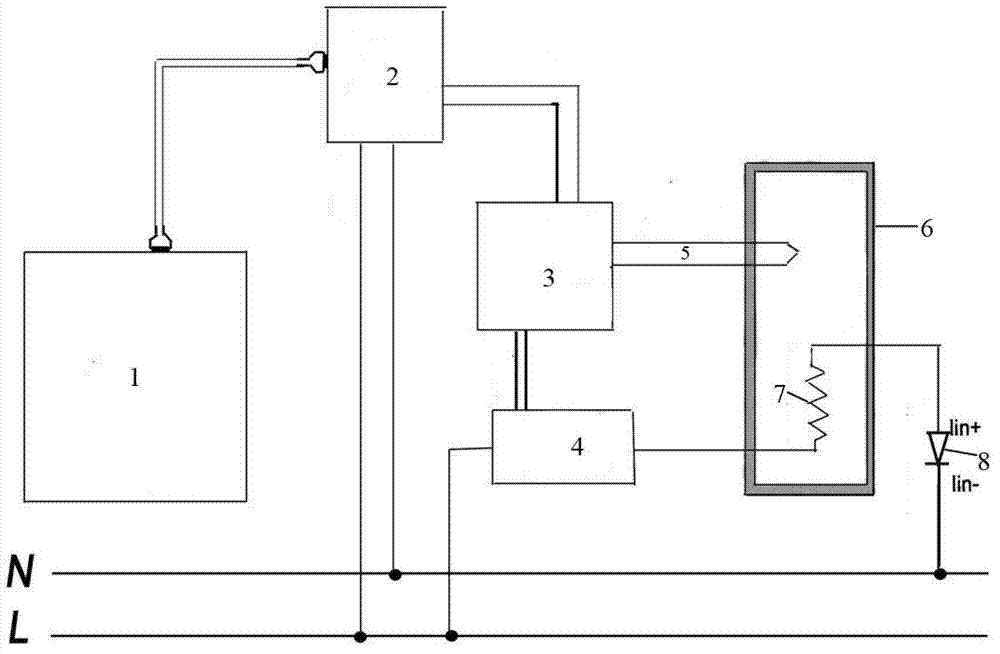

[0061] The sample heating control system is used to heat the sample and control the temperature of the sample, including the sample heating table 6 and the communication converter 2, temperature controller 3, thyristor voltage regulator 4, sample heater 7 and indicator light 8 connected in sequence, the temperature The controller 3 is connected with a precision thermocouple 5, and the precision thermocouple 5 is c...

Embodiment 2

[0089] Infrared emissivity test of a coated Cu sheet sample with a thickness of 0.2mm and an area of 40mm×40mm at 200°C.

[0090] The first step is the assembly of the medium and high temperature infrared emissivity test device

[0091] According to Example 1 Figure 1-Figure 8 Install and connect all of the components to form a medium-high temperature infrared emissivity test device for use in the following steps;

[0092] The use of the high temperature infrared emissivity test device in the second step

[0093] 1) Turn on the computer data processing system, and use the mid-infrared reflectance test system to measure the reference sample (such as gold-plated standard sheet) at a certain temperature T 0 (such as room temperature) reflectivity R 0 (λ, T 0 ), as the background noise reference value of the environment;

[0094] 2) Put the sample to be tested on the sample heating table and fix it, align it with the test hole of the integrating sphere, and set the measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com