Polyvinyl butyral transparent film and preparation method thereof

A polyvinyl butyral, polyvinyl alcohol technology, applied in the direction of adhesives, film/sheet adhesives, adhesive additives, etc., can solve the problems of high price, complicated control of process conditions and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

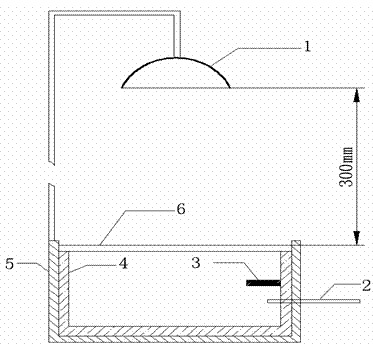

Image

Examples

Embodiment 1

[0031] Step (1): Weigh 100g of PVA and 2000g of distilled water respectively, add them to a four-necked flask equipped with a thermometer, stirrer, and reflux condenser, raise the temperature to 90°C, stir to completely dissolve the PVA, and then cool to room temperature; add 3.2g Sodium dodecylbenzene sulfonate and 20g concentrated hydrochloric acid, at room temperature, use a constant pressure dropping funnel to drip 70g n-butyraldehyde at 10 drops / min. After the addition is complete, keep it for 2h, and then heat up to 50℃ within 2h. React at constant temperature for another 2h, discharge, after cooling to room temperature, neutralize to neutral pH=7 with 5% sodium hydroxide solution, wash the product several times with distilled water to fully remove surfactant and unreacted n-butyraldehyde Wait for impurities, filter by suction, and dry in an oven not higher than 50℃ to obtain PVB products.

[0032] Step (2): Weigh 15g of PVB product prepared in step (1), 0.5g of plasticizer...

Embodiment 2

[0034] Step (1): Weigh 0.15g nano-ATO particles, 0.003g γ-glycidoxypropyltrimethoxysilane, 0.024g hyperdispersant 6300 and 3g ethanol respectively, add them into a single-necked flask, and disperse by 200kHz ultrasonic wave After 40 minutes, a surface modification-treated nano ATO dispersion liquid is obtained.

[0035] Step (2): Weigh 15g of PVB product prepared in Example 1, 0.8g of plasticizer tetraethylene glycol diheptanoate, and 0.2g of antioxidant 2,2 , -Methylene bis(6-tert-butyl-4-methylphenol) and 200g of ethanol are stirred and mixed. After dissolving uniformly, add the nano-ATO dispersion in step (1) to it. After ultrasonic for 50 minutes, continue to stir to make After the ATO is evenly dispersed in PVB, it is poured into a mold at room temperature to form a film, and a PVB / nano ATO film with an ATO content of 1% is obtained.

Embodiment 3

[0037] Step (1): Weigh 0.15g nano-ATO particles, 0.003g γ-glycidoxypropyltrimethoxysilane, 0.024g hyperdispersant 6300 and 3g ethanol respectively, add them into a single-necked flask, and disperse by 200kHz ultrasonic wave After 40 minutes, a surface modification-treated nano ATO dispersion liquid is obtained.

[0038] Step (2): Weigh 15g of PVB product prepared in Example 1, 0.5g of plasticizer tetraethylene glycol diheptanoate, and 0.15g of antioxidant 2,2 , -Methylene bis(6-tert-butyl-4-methylphenol) and 200g of ethanol are stirred and mixed. After dissolving uniformly, add the nano-ATO dispersion in step (1) to it. After ultrasonic for 50min, continue to stir to make After the ATO is evenly dispersed in PVB, it is poured into a mold at room temperature to form a film, and a PVB / nano ATO film with an ATO content of 1% is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com