Preparation method of 3D printing material

A 3D printing and nano-silicon nitride technology, which is applied in the field of 3D printing, can solve the problems affecting the quality of rapid prototyping materials or molded parts, low precision and strength of printing materials, and large gaps in powder particle size, which is conducive to industrialization Promotion, low equipment requirements, small particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

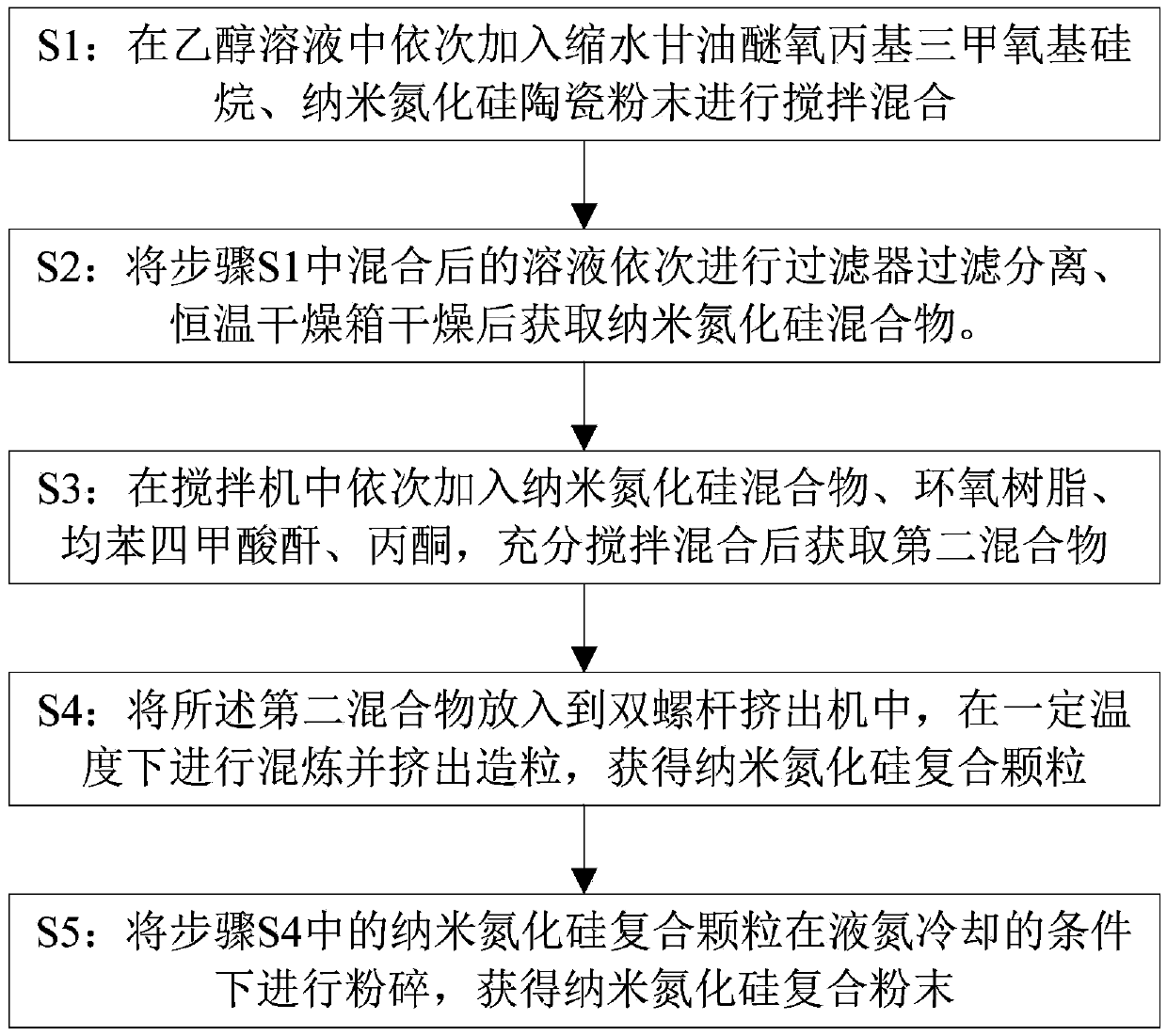

[0022] Such as figure 1 Shown, the preparation method of a kind of 3D printing material of the present invention comprises the following steps:

[0023] S1: Add glycidyl etheroxypropyltrimethoxysilane and nano-silicon nitride ceramic powder in sequence to the ethanol solution for stirring and mixing, and keep a constant temperature of 50°C during stirring, wherein the mass percentage of the ethanol is 35%, and the The mass percent of glycidyl etheroxypropyl trimethoxysilane is 25%, and the mass percent of the nano-silicon nitride ceramic powder is 40%. The particle size of the nano-silicon nitride ceramic powder is 0.1-0.4 μm. The ratio of ethanol to water in the ethanol solution is 1:1.5.

[0024] S2: The solution mixed in step S1 is separated by filter filtration and dried in a constant temperature drying oven to obtain a nano-silicon nitride mixture. The constant temperature drying oven was first dried at a constant temperature of 80° C. for 1 hour, and then dried at a c...

Embodiment 2

[0030] The difference between this embodiment and embodiment 1 is as follows:

[0031] S1: Add glycidyl etheroxypropyltrimethoxysilane and nano-silicon nitride ceramic powder in sequence to the ethanol solution for stirring and mixing, and keep a constant temperature of 60°C during stirring, wherein the mass percentage of the ethanol is 50%, and the The mass percent of glycidyl etheroxypropyl trimethoxysilane is 18%, and the mass percent of the nano-silicon nitride ceramic powder is 32%. The particle size of the nano-silicon nitride ceramic powder is 0.1-0.4 μm. The ratio of ethanol to water in the ethanol solution is 1:0.5.

[0032] S3: Add the nano-silicon nitride mixture, epoxy resin, pyromellitic anhydride, and acetone in step S2 to the mixer in turn, and stir and mix thoroughly to obtain the second mixture. The mass percentage of the nano-silicon nitride mixture is 90% %, the mass percentage of the epoxy resin is 3%, the mass percentage of the pyromellitic anhydride is ...

Embodiment 3

[0034] The difference between this embodiment and embodiment 1 is as follows:

[0035] S1: Add glycidyl etheroxypropyltrimethoxysilane and nano-silicon nitride ceramic powder in sequence to the ethanol solution for stirring and mixing, and keep a constant temperature of 55°C during stirring, wherein the mass percentage of the ethanol is 50%, and the The mass percent of glycidyl etheroxypropyl trimethoxysilane is 20%, and the mass percent of the nanometer silicon nitride ceramic powder is 30%. The particle size of the nano-silicon nitride ceramic powder is 0.1-0.4 μm. The ratio of ethanol to water in the ethanol solution is 1:1.

[0036]S3: Add the nano-silicon nitride mixture, epoxy resin, pyromellitic anhydride, and acetone in step S2 to the mixer in turn, and stir and mix thoroughly to obtain the second mixture. The mass percentage of the nano-silicon nitride mixture is 81 %, the mass percentage of the epoxy resin is 3%, the mass percentage of the pyromellitic anhydride is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com