Micro-lubricating system

A technology of micro-lubrication and flow control valve, which is applied in the direction of engine lubrication, maintenance, safety accessories, mechanical equipment, etc., can solve problems such as low cost, achieve low cost, convenient operation, and solve the effect of large amount of cutting fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

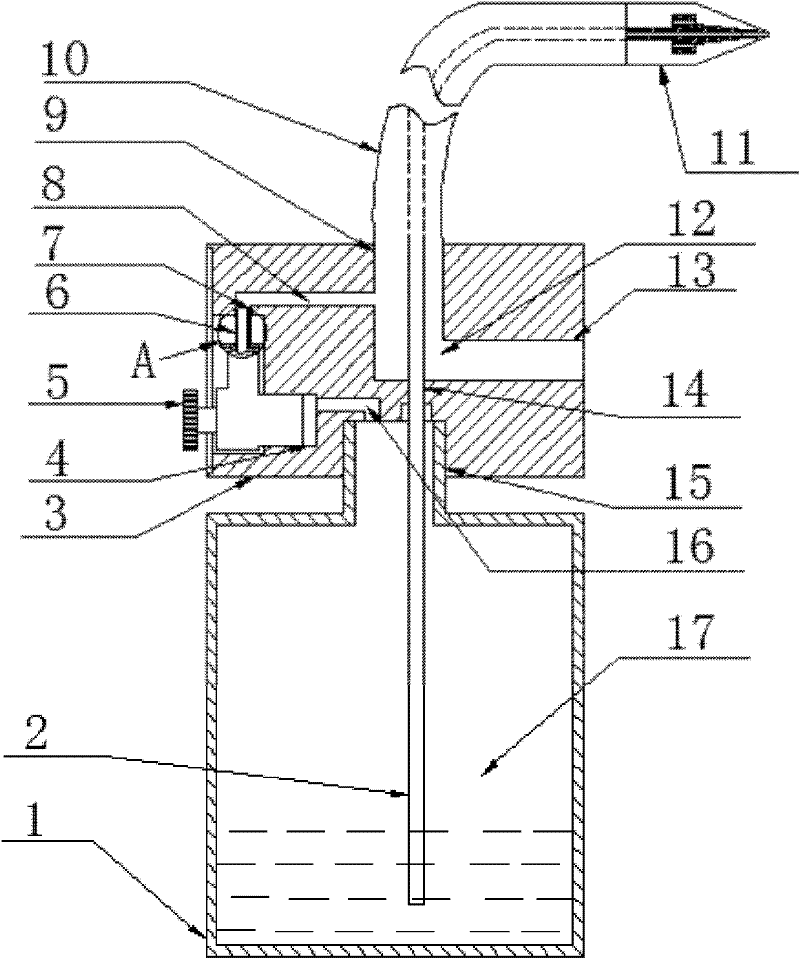

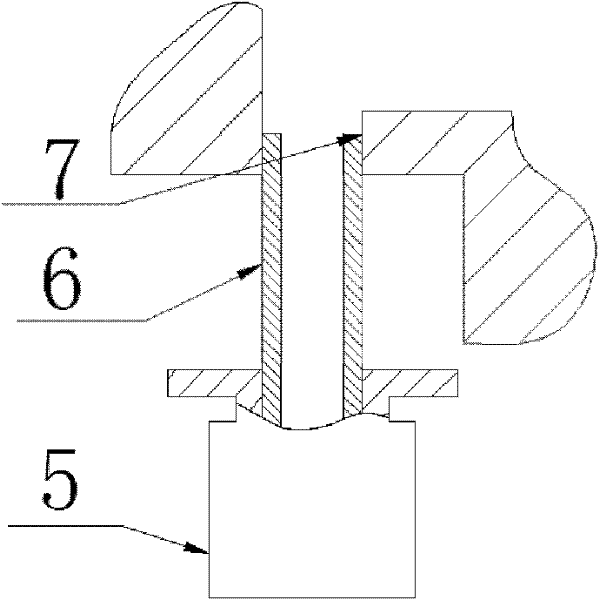

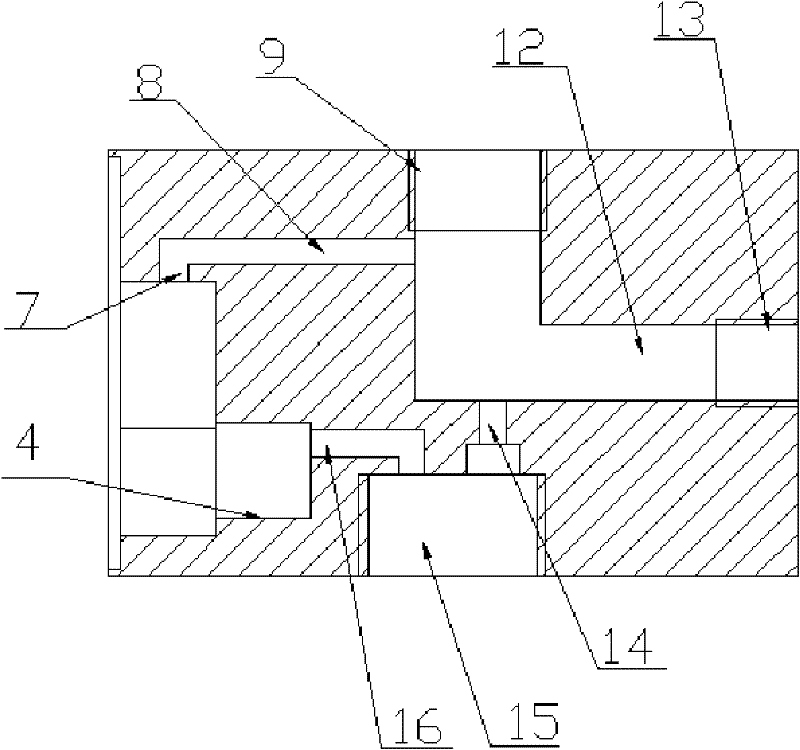

[0028] A minimal quantity lubrication system of the present invention, please refer to figure 1 , figure 2 , image 3 , Figure 4 , including a fuel tank 1, a liquid introduction pipe 2, an upper cover 3, a flow regulating valve 5, an air-introduction thin tube 6, an air outlet pipe 10, and a nozzle 11; the fuel tank 1 and the fuel tank interface 15 of the upper cover are connected by threads to form a hollow closed fuel tank Chamber 17; the upper cover is provided with three chambers, which are the first chamber 12, the second chamber 8 and the third chamber 16; the two ends of the first chamber are the outlet pipe interface 9 and the compressed gas inlet 13 , the second chamber 8 communicates with the third chamber 16 through the flow regulating valve 5; one end of the outlet pipe 10 is connected with the outlet pipe interface 9 of the upper cover, and the other end is connected with the nozzle 11, the nozzle 11 is an inner and outer layer nozzle structure, and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com