Controllable temperature sample table with controllable temperature range of 77K to 400K

A sample stage and range technology, applied in temperature control, non-electric variable control, control/regulation system, etc., can solve the problem of only heating up, and achieve the effect of wide temperature change range, simple structure, and fast dynamic response to temperature change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings.

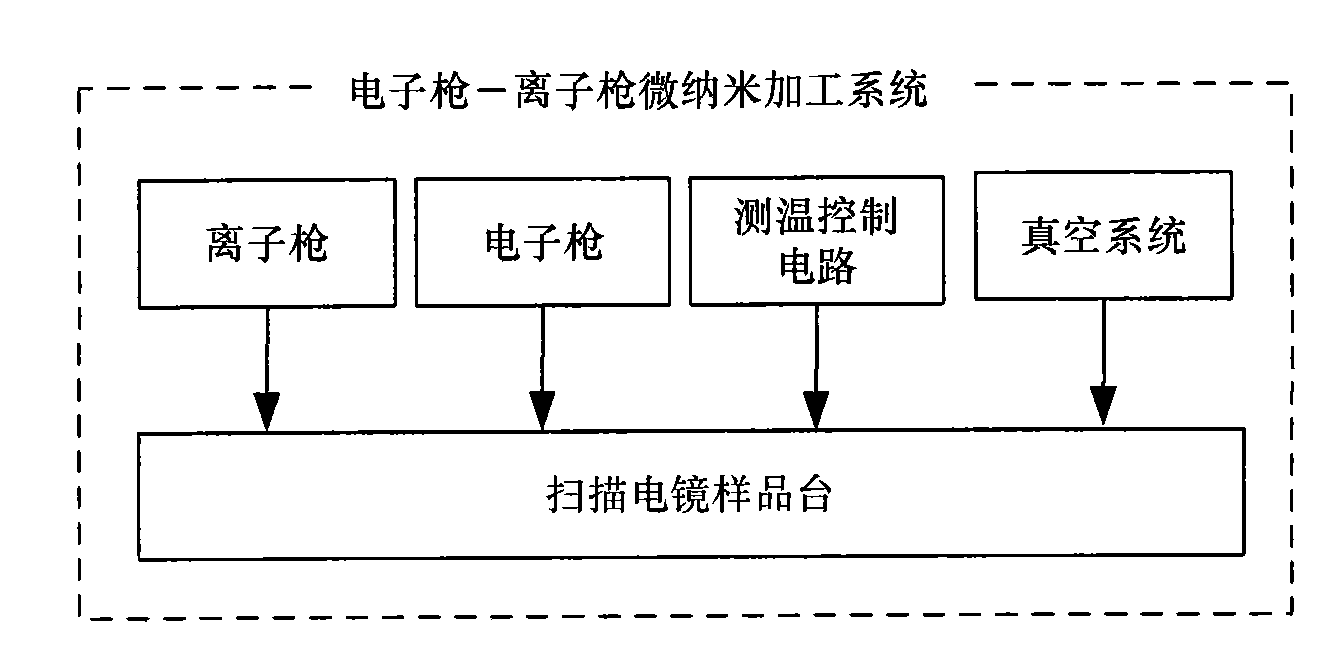

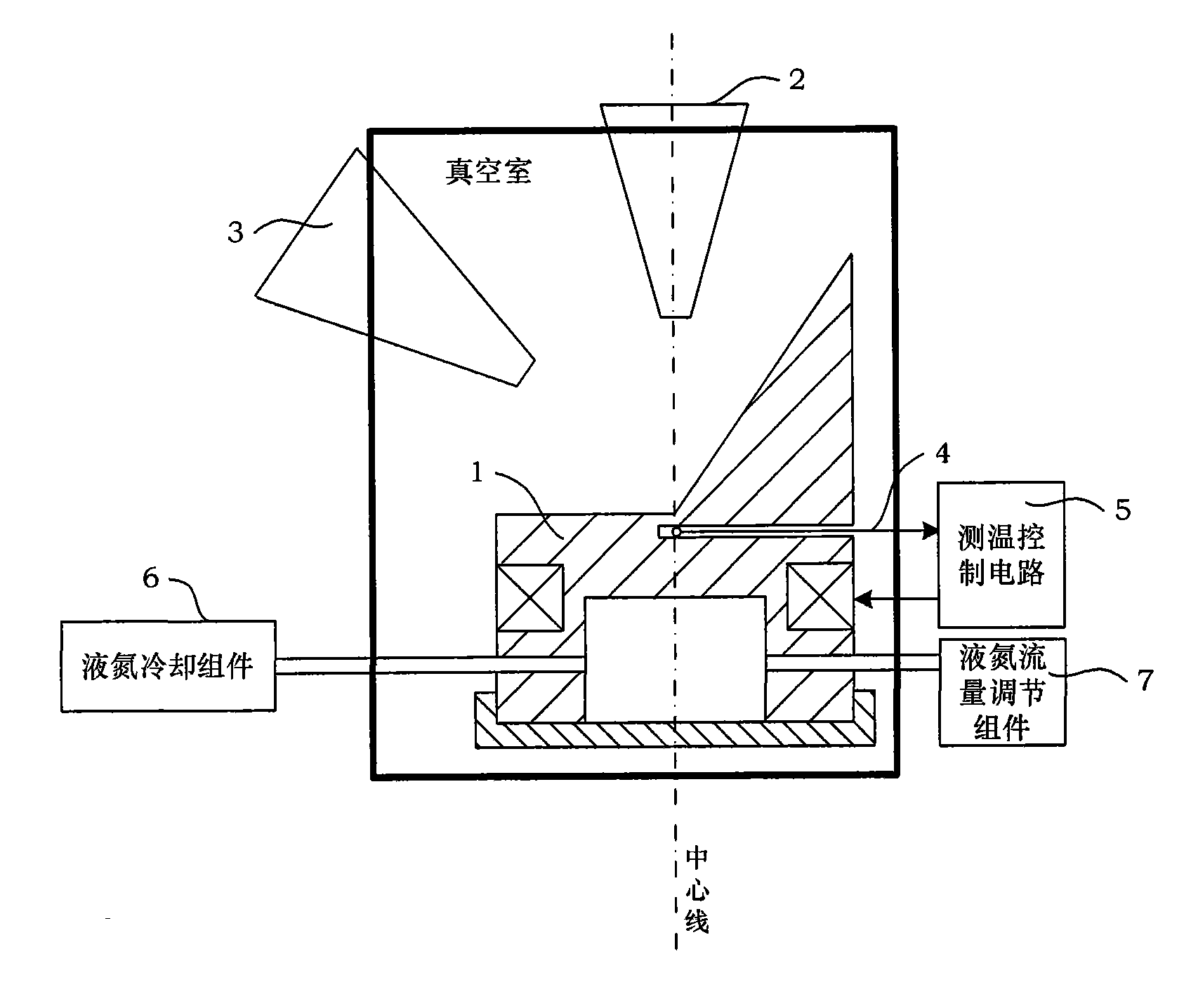

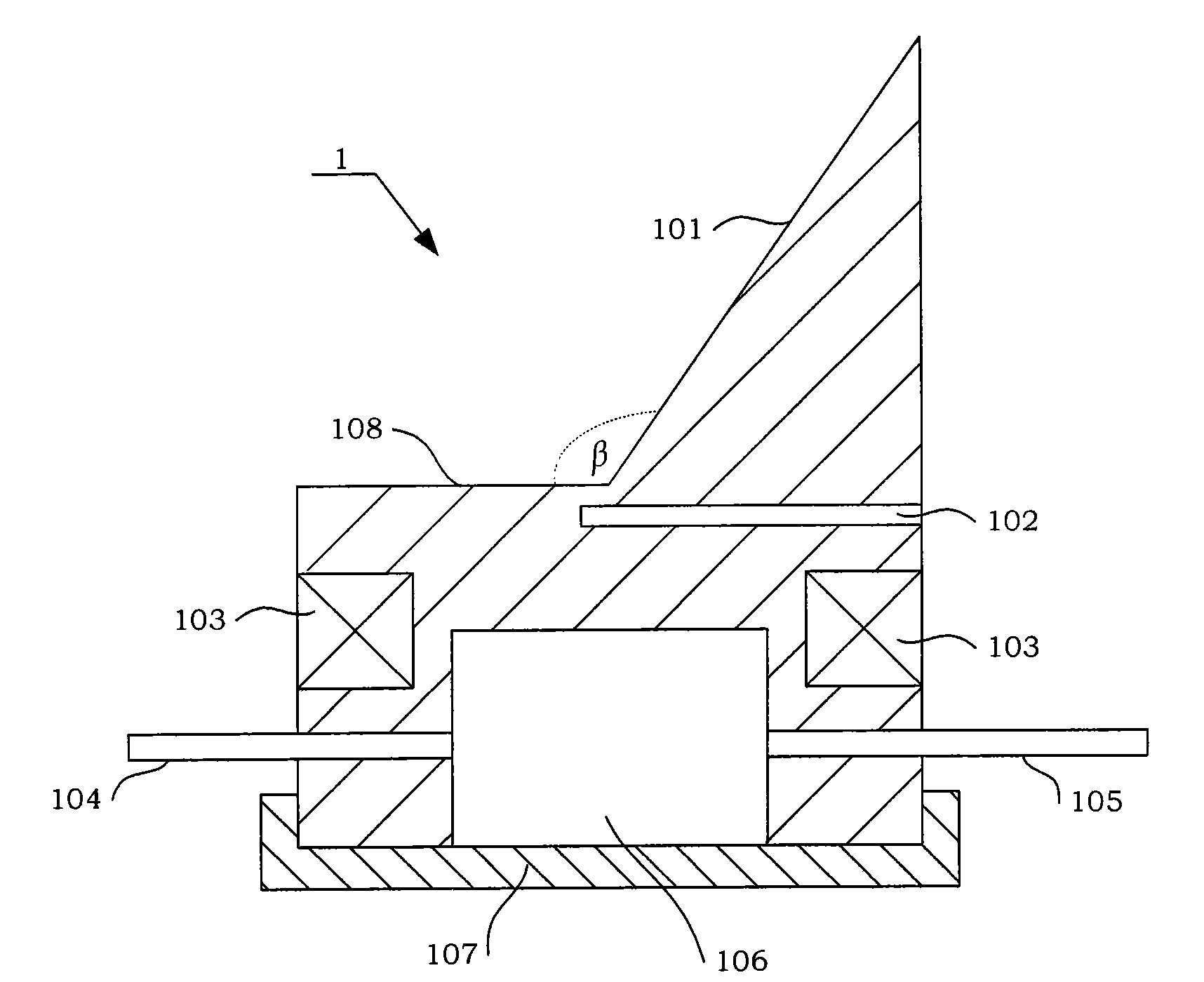

[0019] see figure 1 As shown, a temperature-controllable sample stage suitable for electron beam-ion beam micro-nano processing system of the present invention, the temperature-controllable sample stage is composed of a temperature-controlled sample stage 1 and a liquid nitrogen cooling assembly 6, and the liquid nitrogen cooling assembly 6 provides a cooling medium for the temperature-controlled sample stage 1; the output of liquid nitrogen is realized through the liquid nitrogen flow regulating assembly 7 between the temperature-controlled sample stage 1 and the liquid nitrogen cooling assembly 6 . The temperature-controllable sample stage is based on the addition of a temperature-controlled sample stage 1 and a liquid nitrogen cooling assembly 6 in the existing electron beam-ion beam micro-nano processing system. The temperature-controlled sample stage 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com