Magnetic material processing device capable of reaching 1600 DEG C

A material processing and magnetic field technology, applied in the field of magnetic field material processing devices, can solve the problems of insufficient sample size and low temperature, and achieve the effects of convenient testing, large space and increased size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

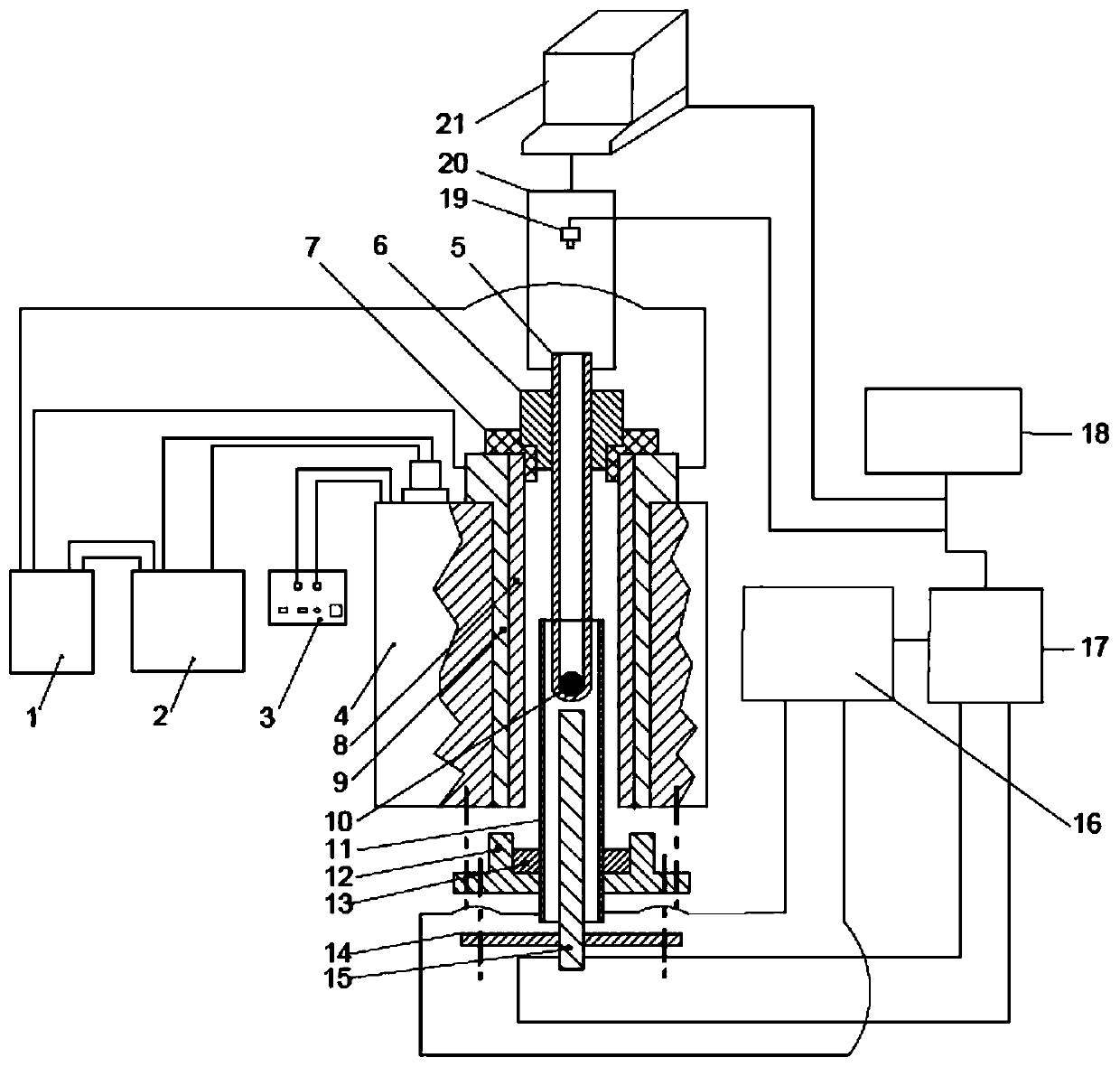

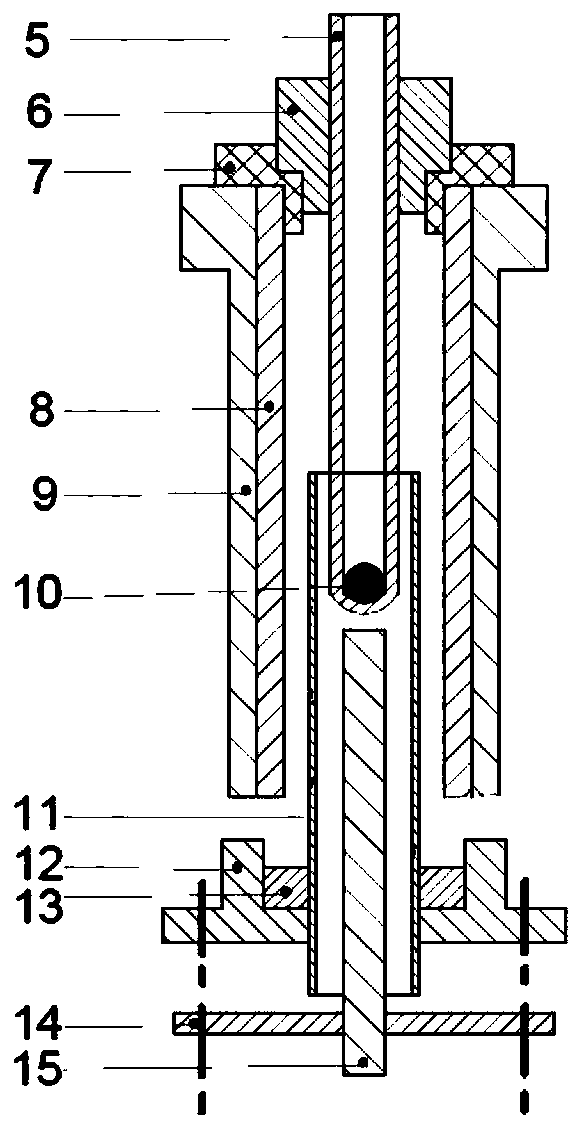

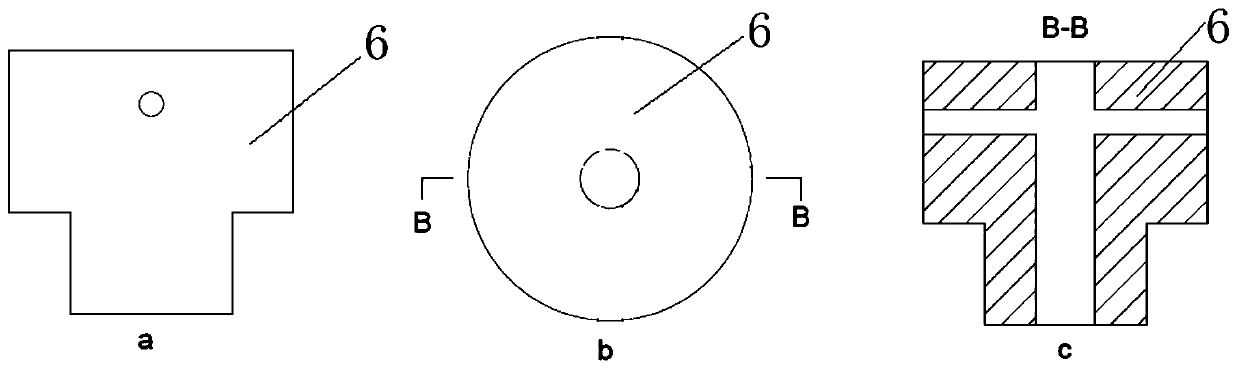

[0036] This embodiment is a magnetic field material processing device with a temperature up to 1600°C, including a water cooler 1, a compressor 2, an excitation power supply 3, a superconducting magnet 4, a quartz tube 5, a copper sleeve 6, a copper end cover 7, and an insulating layer 8. Water cooling layer 9, heating body 11, tray 12, insulated refractory disk 13, thermocouple fixing plate 14, thermocouple 15, heating power supply 16, infrared probe 19, Eurotherm controller 17, computer 18, test tube holder 20 and balance twenty one. in:

[0037] The lower end of the quartz tube 5 is loaded into the heating body 11 through the copper sleeve 6; the upper end of the thermocouple 15 is loaded into the heating body 11 through the thermocouple fixing plate 14; and the lower end of the quartz tube is There is a distance of 10-20 mm between the end face and the upper end face of the thermocouple. The heating body 11 is located in the insulation layer 8, and there is a distance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com