Experimental simulation device for relieving near-wellbore plugging of gas-condensate well and simulation method

An experimental simulation, condensate gas well technology, which is applied to measurement devices, analytical materials, material inspection products, etc., can solve the problems of unsatisfactory reverse condensate effect and short seepage channels, so as to release formation water lock, facilitate observation, reduce The effect of hold-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

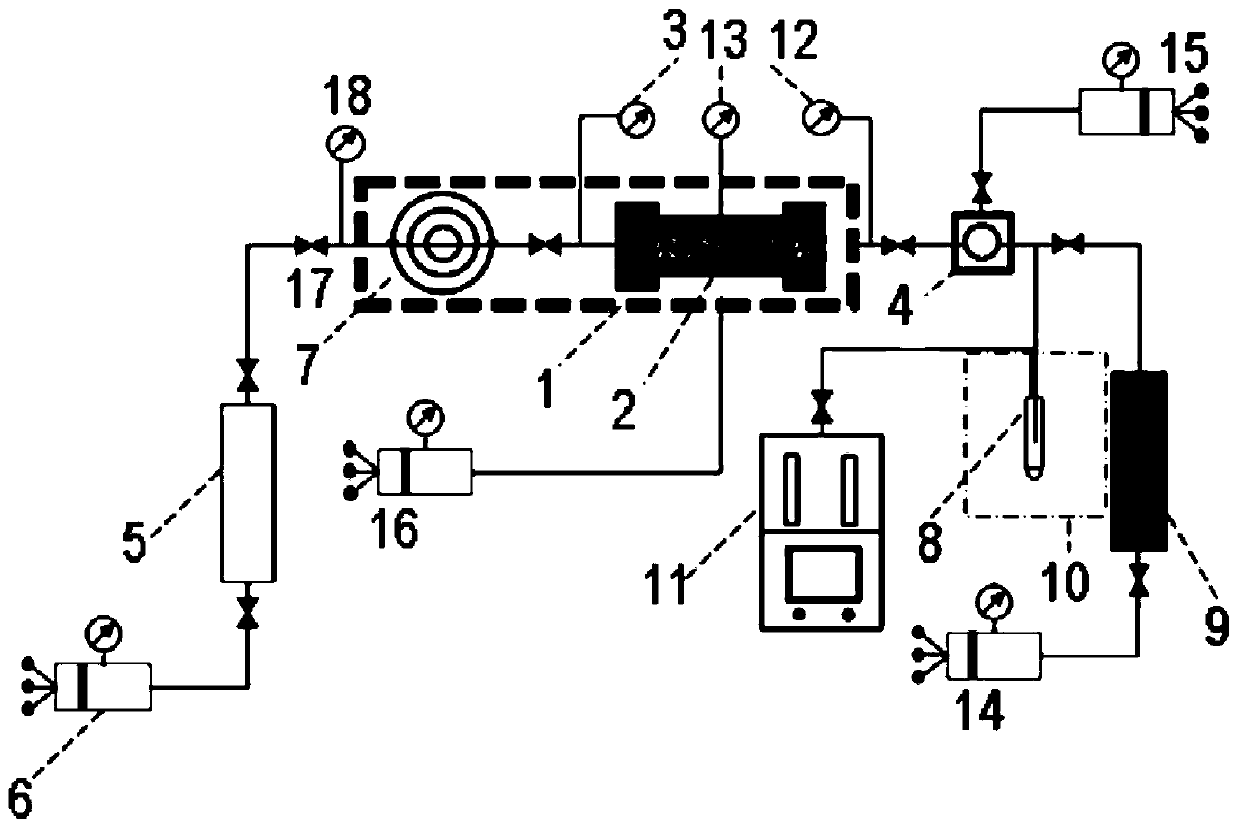

[0058] This embodiment provides an experimental simulation device for removing blockage near the well of a condensate gas well. The schematic diagram of the device is as follows figure 1 shown, from figure 1 It can be seen that it includes:

[0059] Adjustable constant temperature oven 1, long core holder 2, thin sand-filled tube 7, condensate gas sample storage tank 5, ethanol sample storage tank 9, condensate oil collection pipe 8, liquid nitrogen cooling system 10 and automatic gas meter 11;

[0060] The long core holder 2 is used to place the target long core for simulating the near-wellbore zone; the condensate gas sample storage tank 5 passes through the pipeline sequentially through the intake valve 17 and the third high-precision pressure monitoring gauge 18 and the The thin sand-filling tube 7 is connected, and the thin sand-filling tube 7 is connected to the inlet end of the long core holder 2 through the pipeline through the first high-precision pressure monitorin...

Embodiment 2

[0068] This embodiment provides an experimental simulation method for unblocking near-well of condensate gas wells, wherein the method utilizes the experimental simulation device for unblocking near-well of condensate gas wells provided in Example 1, and the method specifically includes the following steps :

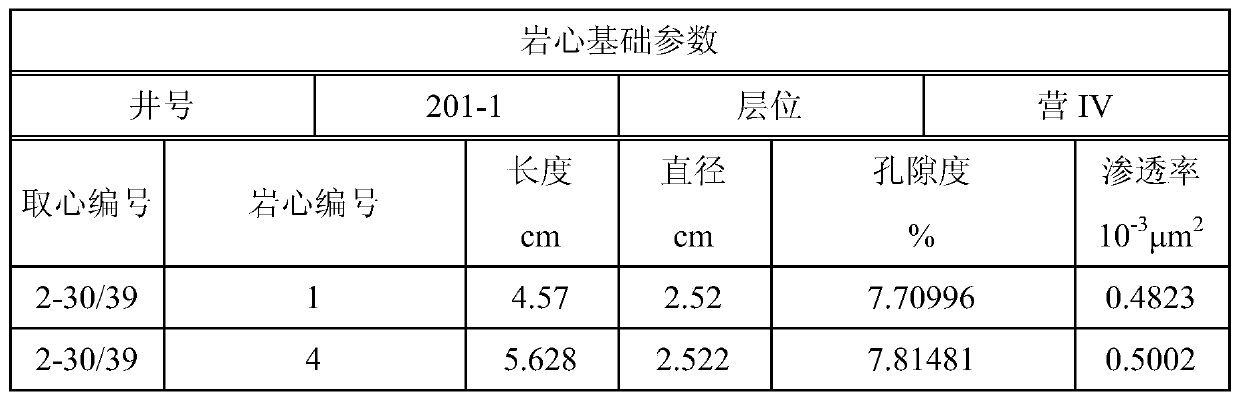

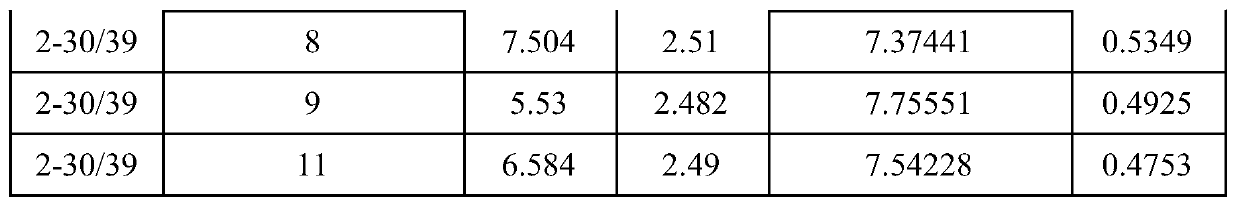

[0069] (1) Weigh a number of short cores in turn and test the porosity of the cores, evacuate these short cores and fully saturate the formation water (generally, it will be saturated with formation water for one day), and then centrifuge with a centrifuge to remove possible porosity in the cores. Weigh again after flowing water until the cores meet the requirement of irreducible water saturation, and then sort these short cores according to the harmonic average and then put them into the rubber bucket and put them into the long core holder, and set the temperature of the constant temperature box (1) to the experimental value. Formation temperature, measuring the permeab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com