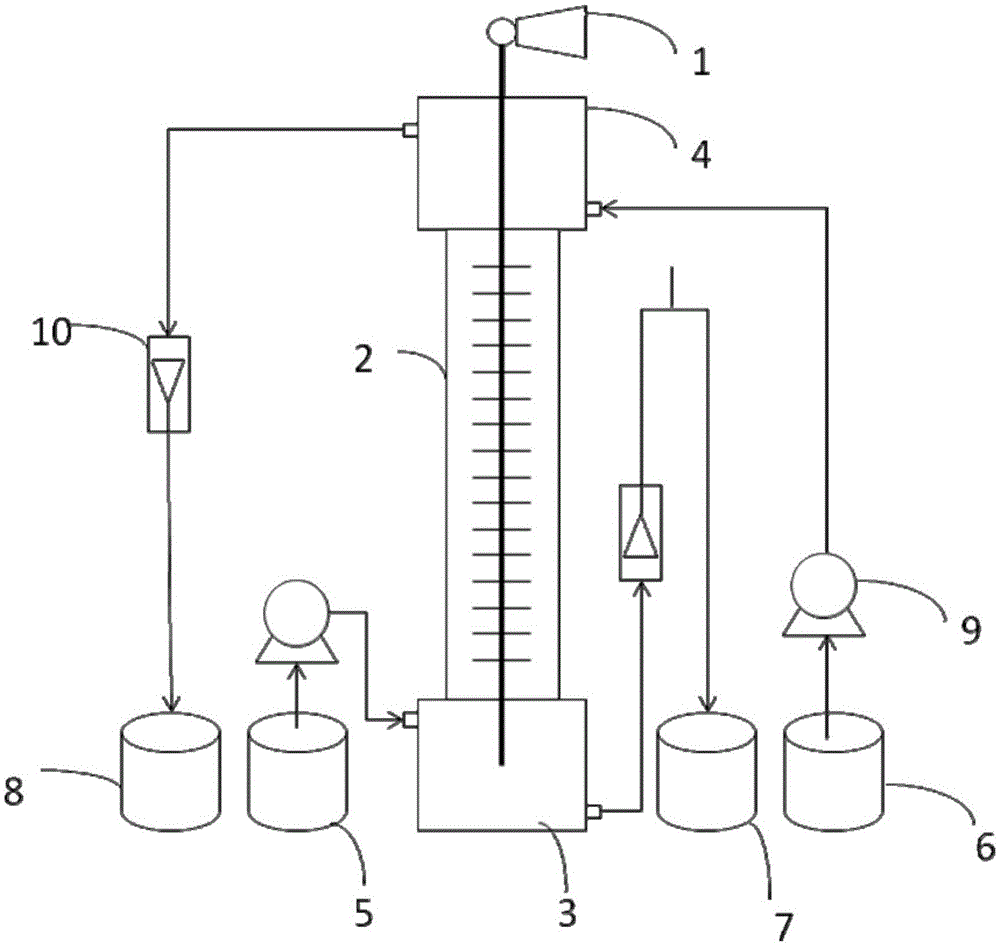

Tower type extraction device, tower extraction process method and application

A technology of extraction equipment and process method, which is applied in chemical instruments and methods, extraction water/sewage treatment, liquid solution solvent extraction, etc., can solve the problems of low flux of extraction tower, etc. The effect of increased flooding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

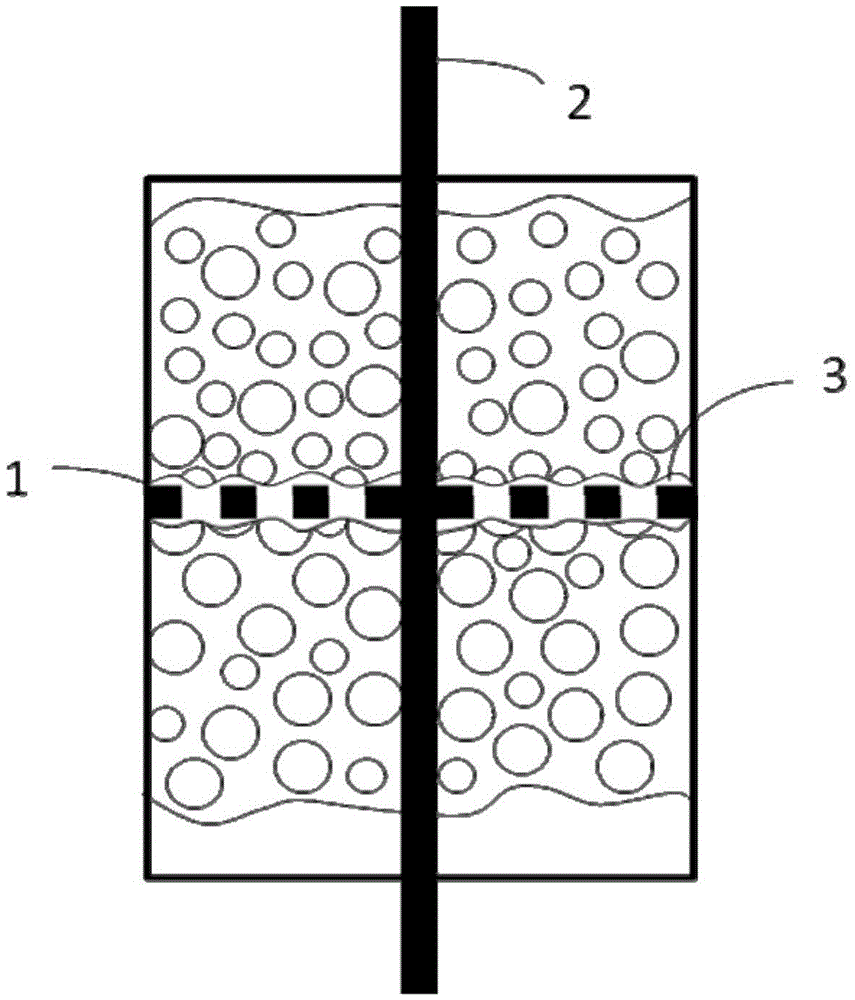

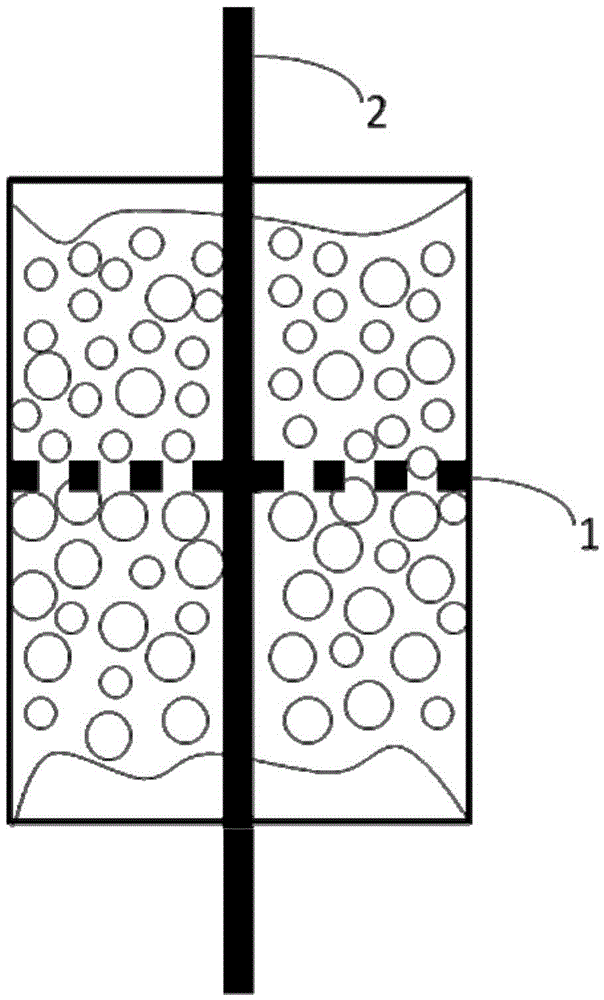

Embodiment 1

[0041] In the vibrating sieve plate extraction tower with an inner diameter of φ50mm, the sieve plate has a sieve hole diameter of φ6mm, an opening ratio of 48%, a plate spacing of 35mm, a gap of 0.2mm between the plate and the column, an amplitude of 9mm, and a vibration frequency of 100 times / minute. TBP-kerosene (TBP mass fraction 80%) is used as the dispersed phase, brine is used as the continuous phase, and the lithium ion is extracted by using this equipment. The tower body is made of glass, and the main shaft and sieve plate in the tower body are the two-phase dispersed contact materials described in the present invention. Since the continuous phase is the water phase and the dispersed phase is the organic phase, the main shaft and sieve plate materials in the tower are selected from ethylene vinyl alcohol copolymer (EVAL) materials with strong hydrophilic properties. When the vibrating sieve tray extraction tower is started up, the continuous phase is firstly filled i...

Embodiment 2

[0049] The packed extraction tower with an inner diameter of φ50mm is filled with φ10 Raschig ring packing, and the specific surface area is a p =352m 2 / m 3 , porosity ε=0.616. Tower material selects glass, the brine after the continuous phase flotation of boric acid, the dispersed phase is the mixed solvent of 2-ethylhexanol and kerosene (volume ratio is 1:1), the concentration of boron in the brine is 8g / L (in B 2 o 3 ), the boron in the brine is extracted by using a packed tower using 2-ethylhexanol as an extractant. Raschig ring packing choose PP material and EVAL material. When the continuous phase chooses the water phase as the continuous phase, choose a hydrophilic material, that is, the EVAL material is the Raschig ring filler; when the continuous phase is the organic phase, choose the lipophilic material, that is, the PP material is the Raschig ring filler. High fluxes can be achieved due to the good wetting properties of both materials to the corresponding cont...

Embodiment 3

[0053] In the vibrating sieve plate extraction tower with an inner diameter of φ50mm, the sieve plate has a sieve hole diameter of φ3mm, an opening rate of 48%, a plate spacing of 50mm, a gap of 0.2mm between the plate and the column, an amplitude of 9mm, and a vibration frequency of 150 times / min. Methyltrioctylammonium chloride-o-dichlorobenzene (mass fraction of o-dichlorobenzene 80%) is used as the organic phase, lithium chloride lithium hydroxide solution is the water phase, and this equipment is used to extract the lithium 7 element. The material of the tower body is glass. The continuous phase is an organic phase, and the dispersed phase is an aqueous phase. In this system, the aqueous phase is the light phase with a lithium concentration of 3.5 mol / L, and the organic phase is the heavy phase. The water phase is injected into the tower from the lower part of the tower through the peristaltic pump, and rises by the buoyancy force; the organic phase is injected from the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com