Non-penetration laser welding method

A technology of penetration welding and laser welding head, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc. It can solve the problems of oxidative discoloration, burn deformation on the back of the weld, and poor stability, so as to reduce heat accumulation and weld melting. The effect of improving deep stability and reducing welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

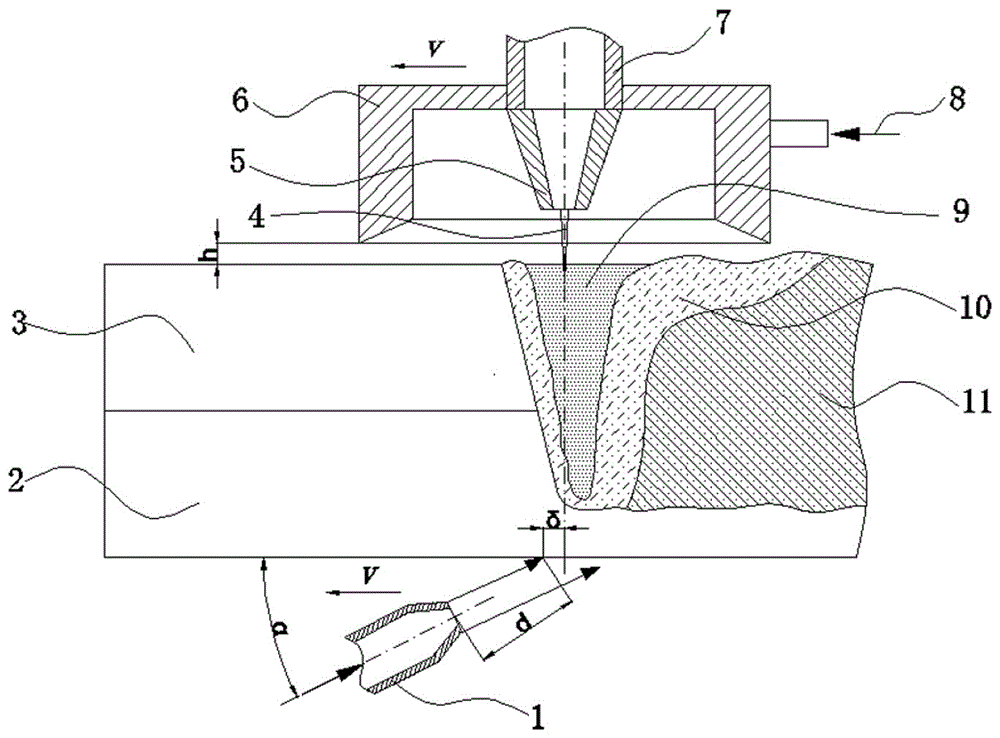

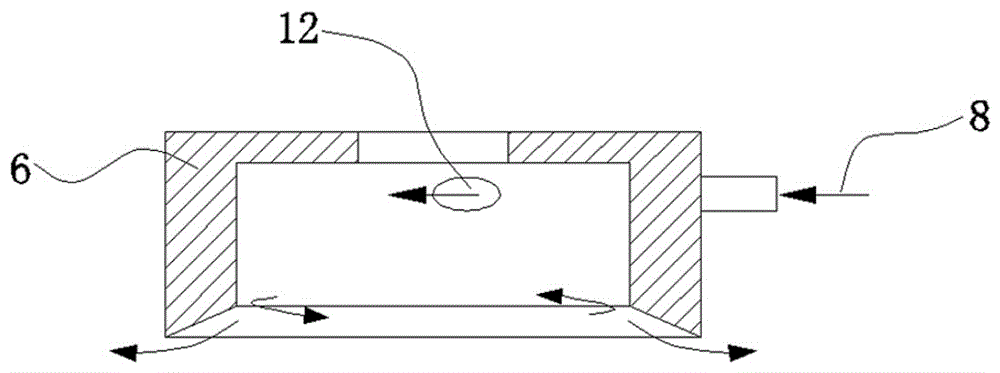

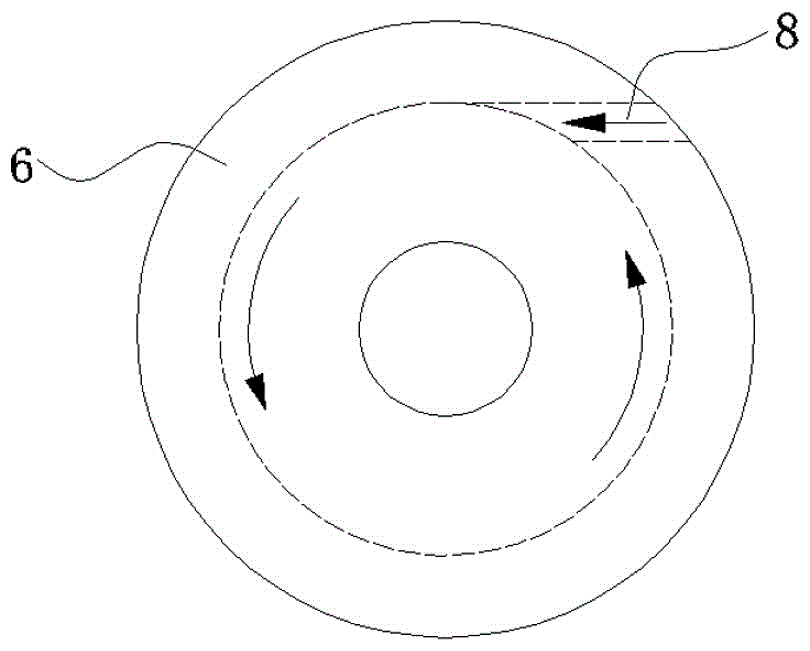

[0036] The following will be combined with Figure 1-3 Specific embodiments of the present invention will be described in detail.

[0037] like figure 1 As shown, the welding object is a lap joint of large structural plates with a thickness of 1 mm to 5 mm. The vacuum cover installed on the welding head forms a partial vacuum environment in the laser welding area, and the laser beam is vertically incident on the upper surface of the workpiece to achieve deep penetration welding. Industrial liquid nitrogen is sprayed at the bottom synchronously to realize the laser non-penetration welding connection of the two plates.

[0038] The technical solution of the present invention is to provide a laser non-penetration welding method, which is characterized in that:

[0039] Step 1: Remove impurities on the upper and lower surfaces of the first base material 2 and the second base material 3, these impurities include water stains, oil stains, rust and other impurities that have an imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com