Electro-plastic two-roll mill of low-temperature liquid nitrogen cooling medium

A technology of cooling medium and low temperature liquid nitrogen, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problem of size limitation, reduce deformation resistance, inhibit grain recovery, and improve plastic deformation effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

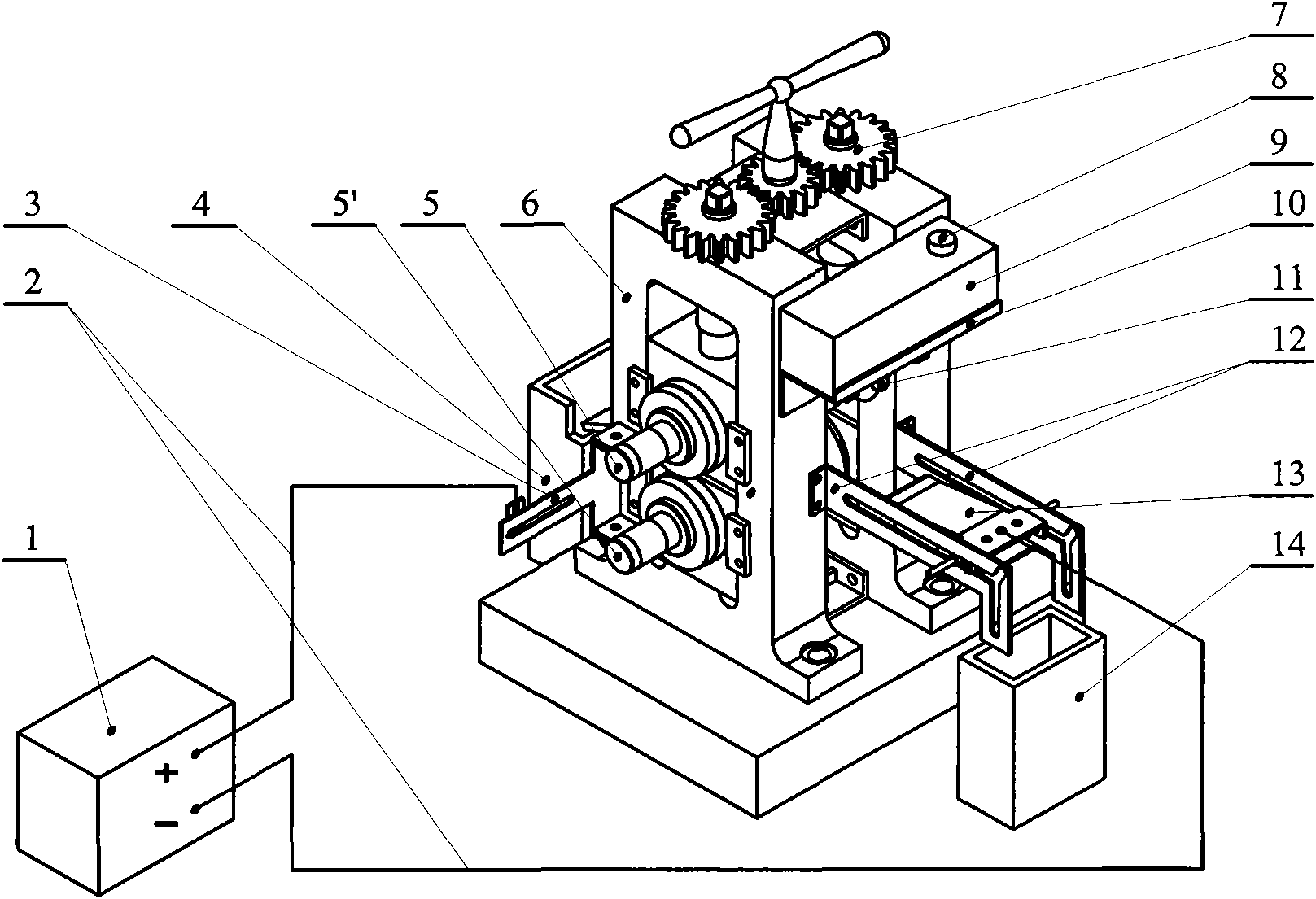

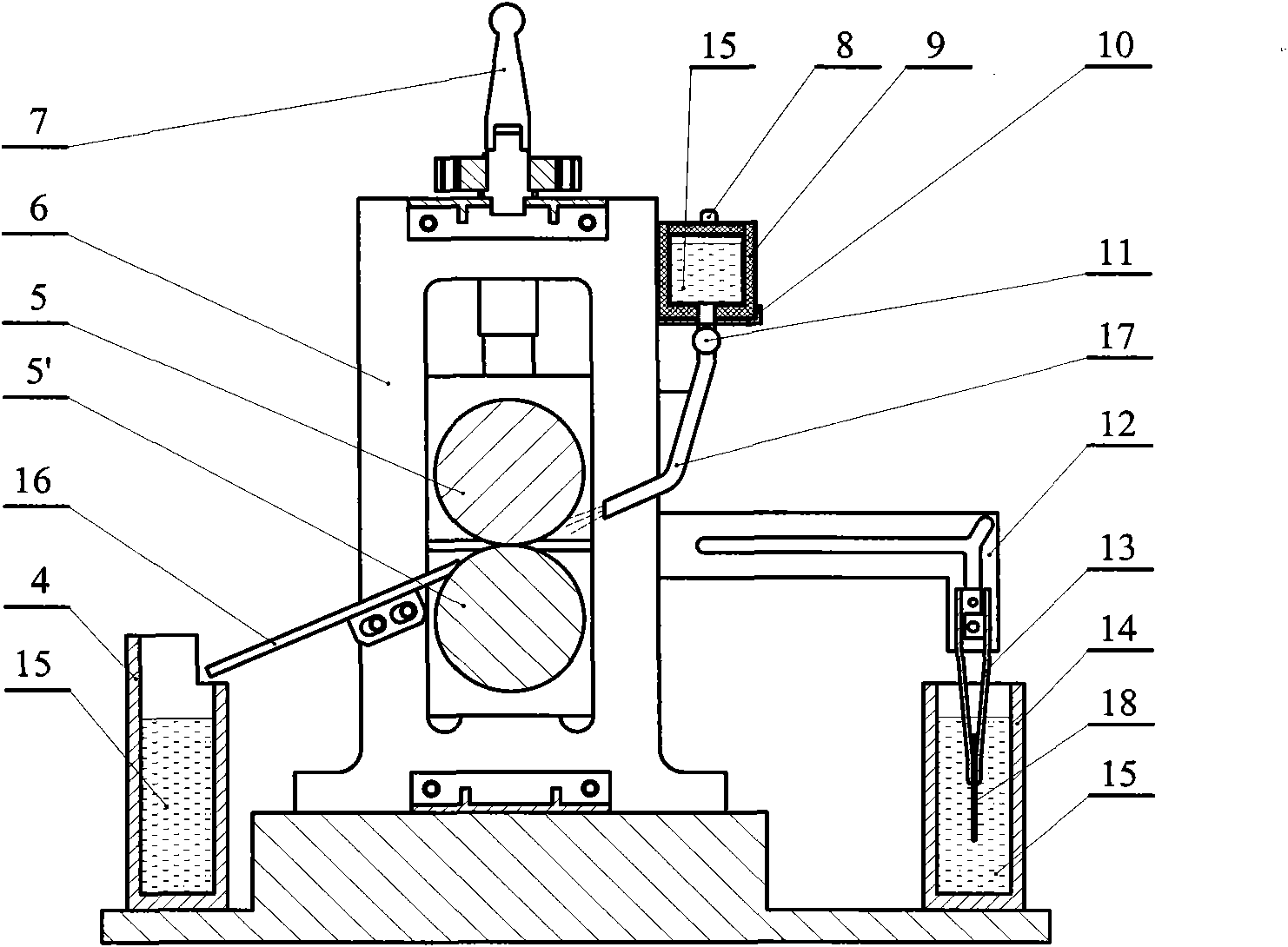

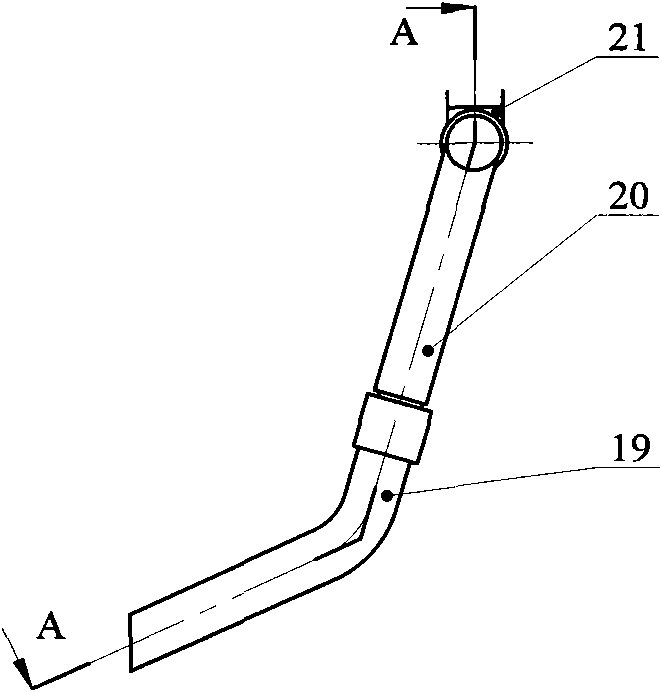

[0018] figure 1 , figure 2 It is an electroplastic two-roll rolling mill disclosed by the invention as a low-temperature liquid nitrogen cooling medium, and the nominal diameter of the roll body is 90mm. The electroplastic two-roll rolling mill of the low-temperature liquid nitrogen cooling medium includes a transmission part and a working frame part. The transmission part has a motor, a frequency converter and a gear distribution box, and the input of the motor is transmitted to the upper and lower rolls (5, 5'), the frequency converter is used to realize the stepless speed regulation of the motor. The working stand is composed of a roller system, a frame 6 and a pressing mechanism 7. The rollers refer to upper and lower rolls (5, 5′) and corresponding bearing housings and other parts. The roller system is placed in the window of the frame 6, and the frame 6 is a closed frame. The depressing mechanism 7 adopts the form of depressing screws, and manually depresses to adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com