Ultrasonic gas or cluter injector

An injector and gas technology, which is used in the reduction of greenhouse gases, climate sustainability, nuclear reactors, etc., can solve the problems of low gas particle orientation velocity, low orientation velocity, restricting the shape of the nozzle, etc., to promote the peaking of the plasma density distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

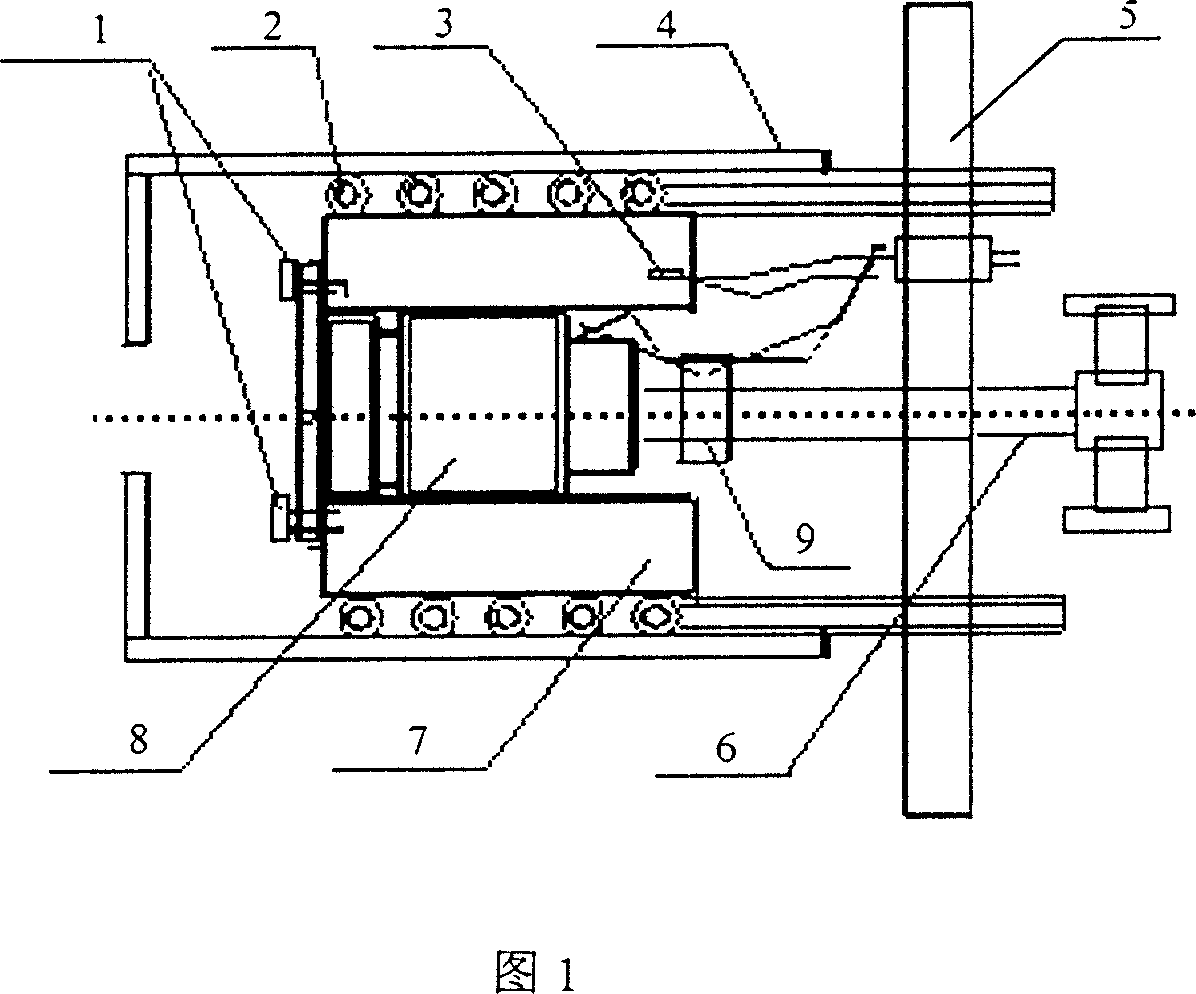

[0008] As shown in Figure 1, the ultrasonic gas or cluster injector includes a valve assembly, the valve assembly is fixed on the CF150 flange 5 connected with the vacuum chamber pipeline of the circulator, and the valve assembly is a gas jet valve 8 with a Laval nozzle, The valve can be purchased directly, the model is Series99, and other models with similar structure can also be selected or designed and manufactured by ourselves, but it is required to have the performance of vacuum and high pressure sealing at the temperature of liquid nitrogen. The gas jet valve 8 is connected to the high-pressure gas delivery pipe 6 through an A-lock connector 9, which can be vacuum-tight and can withstand an air pressure of 10 MPa. A liquid nitrogen cold trap 7 is arranged outside the gas jet valve 8, and the liquid nitrogen cold trap is a copper container filled with liquid nitrogen, which helps to improve heat transfer efficiency. The liquid nitrogen is injected into the copper container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com