Wear-resisting waterproof flame-retardant wooden floor and manufacturing method thereof

A floor and wood technology, which is applied in the field of wood floor and wood floor preparation, can solve the problems of not having a solid wood feeling, formaldehyde release hazards, etc., and achieve the effects of less usage, expanded use range, and lower cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

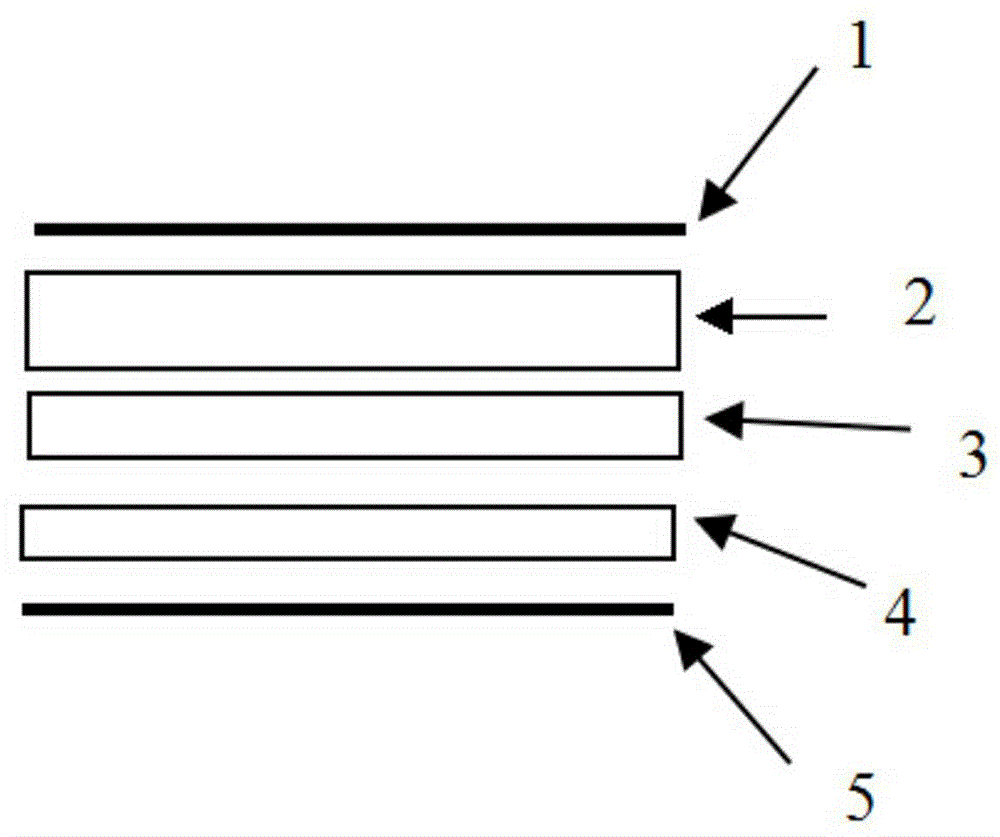

[0034] In Embodiment 1, the wear-resistant, waterproof, and flame-retardant wooden floor is a multi-layer composite structure, and its structure is as follows: figure 1 As shown, from top to bottom are the decorative wear-resistant waterproof layer veneer 1, the upper inorganic flame-retardant layer 2, the veneer reinforcement layer 3, the lower inorganic flame-retardant layer 4, and the fast-growing wood veneer 5. Moreover, the internal bonding strength of the wear-resistant, waterproof, and flame-retardant wooden floor is 0.75 MPa, the flame-retardant grade reaches A2 level, and the dimensional stability of moisture and heat resistance is 0.37% in the length direction and 1.05% in the width direction.

[0035] Its concrete preparation steps can be expressed as:

[0036](1) Preparation of inorganic flame retardant layer: use inorganic adhesive (ratio by mass: magnesium oxide: magnesium chloride: water: ammonium polyphosphate: trisodium phosphate: coupling agent: tartaric acid...

Embodiment 2

[0044] In Embodiment 2, the wear-resistant, waterproof, and flame-retardant wooden floor is a multi-layer composite structure, and its structure is as follows: figure 1 As shown, from top to bottom are the decorative wear-resistant waterproof layer veneer 1, the upper inorganic flame-retardant layer 2, the veneer reinforcement layer 3, the lower inorganic flame-retardant layer 4, and the fast-growing wood veneer 5. Moreover, the internal bonding strength of the wear-resistant, waterproof, and flame-retardant wooden floor is 0.80 MPa, the flame-retardant grade reaches A2-B1 level, and the dimensional stability of moisture and heat resistance is 0.35% in the length direction and 0.97% in the width direction.

[0045] Its concrete preparation steps are as follows:

[0046] (1) Preparation of inorganic flame retardant layer: use inorganic adhesive (ratio by mass: magnesium oxide: magnesium chloride: water: ammonium polyphosphate: trisodium phosphate: coupling agent: tartaric acid=...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com