Lithium ion secondary battery and electrolyte thereof

A technology for secondary batteries and electrolytes, applied in secondary batteries, circuits, electrical components, etc., can solve the problems that the thickness expansion improvement effect is not too obvious and the effect is not ideal, and achieves excellent high-temperature storage performance and excellent cycle performance. , the effect of preventing decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

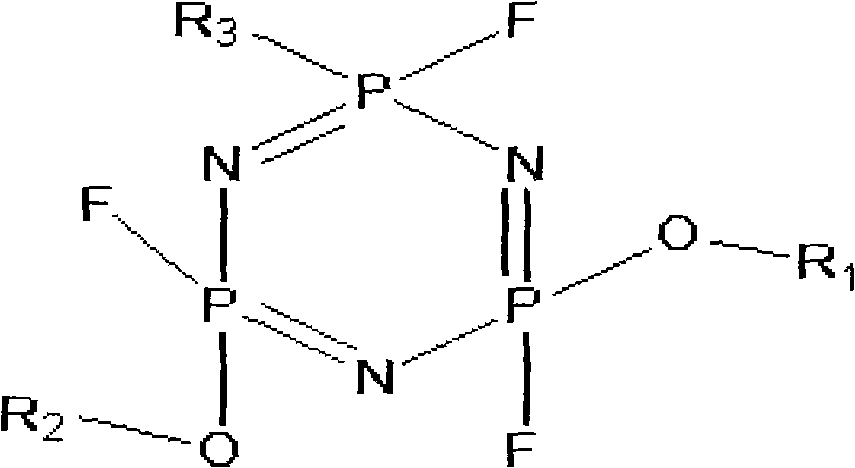

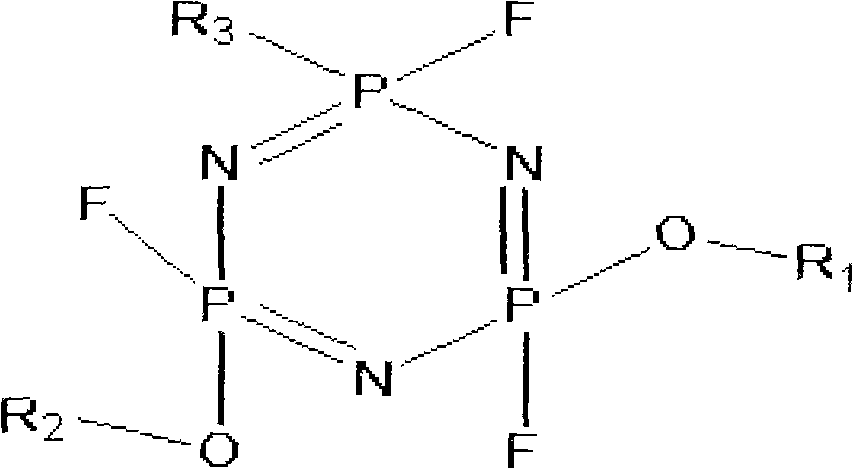

Method used

Image

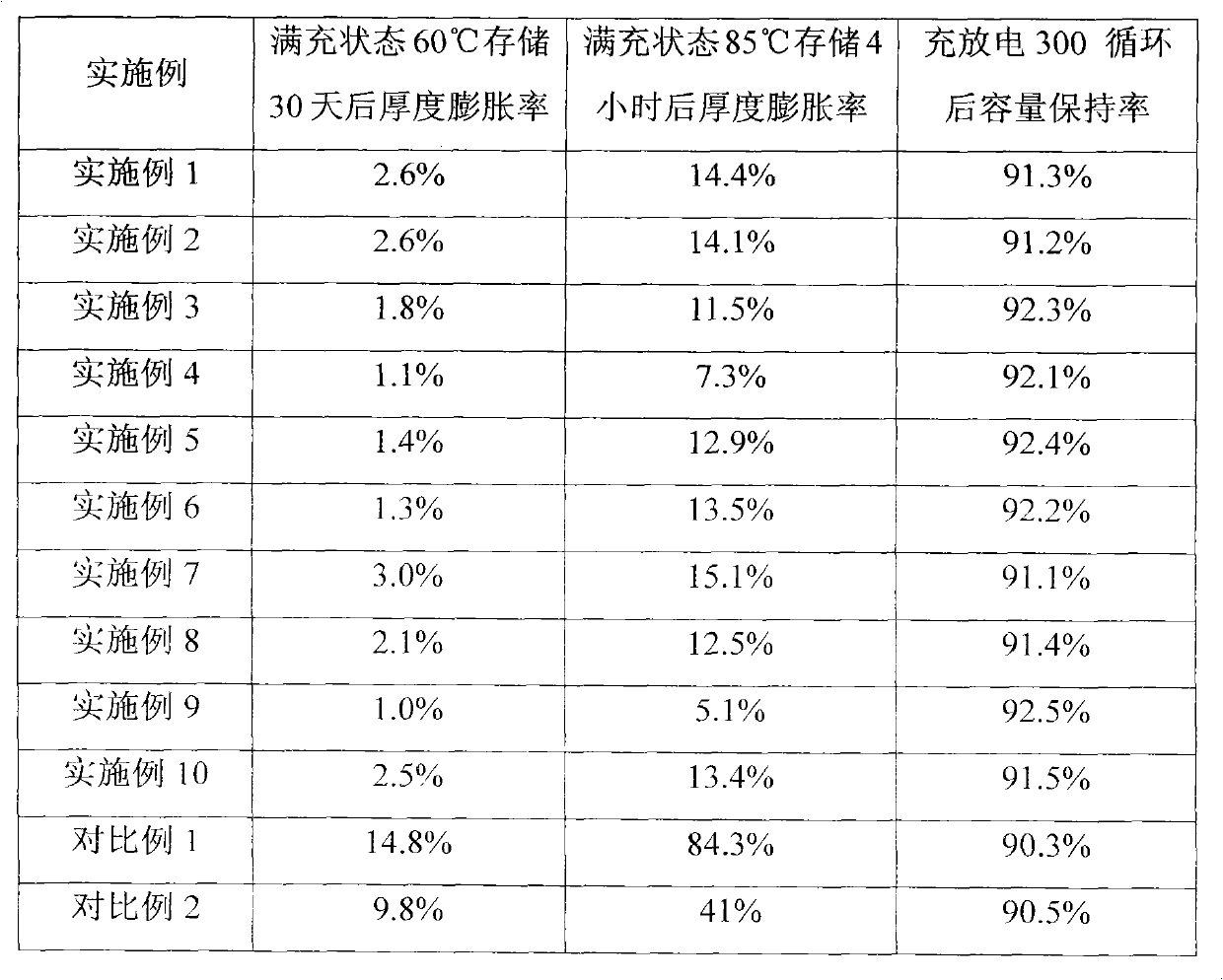

Examples

Embodiment 1

[0035] Preparation of cathode sheet:

[0036] The positive electrode active material lithium cobaltate (LiCoO 2 ), conductive carbon (Super-P) and polyvinylidene fluoride (PVDF) are mixed in the solvent according to the mass ratio of 95:2:3, and stirred evenly to obtain the cathode slurry. The slurry is coated on a 9 μm aluminum foil, dried, and cold pressed to obtain a compacted density of 1.6 g / cm 3 The pole piece is then cut and welded to obtain the cathode piece.

[0037] Preparation of anode sheet:

[0038] The negative electrode active material natural graphite, conductive carbon (Super-P) and sodium carboxymethylcellulose (CMC) were mixed in the solvent according to the mass ratio of 95:2:3, and stirred evenly to obtain the anode slurry. Coat the slurry on a 9μm copper foil, dry, and cold press to obtain a compacted density of 1.7g / cm 3 The pole piece is cut and welded to obtain the anode piece.

[0039] The separator adopts a polypropylene (PP) porous membrane wit...

Embodiment 2

[0045] Different from Example 1, the positive electrode active material is lithium nickel cobalt manganese oxide (LiNi 0.4 co 0.3 mn 0.3 o 2 ) and lithium nickelate (LiNiO 2 ), the mass ratio of the two is 1:1; the negative electrode active material is a mixture of hard carbon and soft carbon, and the mass ratio of the two is 3:1; the separator adopts a polyethylene (PE) porous film with a thickness of 16 μm.

[0046] The electrolyte was prepared as follows:

[0047] Mix the non-aqueous solvent butylene carbonate, dimethyl carbonate, ethyl formate and fluorobenzene in a mass ratio of 3:1:0.1:0.2, let stand for 30 minutes, and then add 2% and 3% of 1 by mass, 3-propane sultone and vinylene carbonate, then lithium salts (lithium difluorooxalate borate (LiDFOB) and LiBF 4 The mixture of the two, the mass ratio of the two is 4:1), so that it is fully dissolved, and the concentration of the lithium salt is 0.85M. Finally add 2,4,6-trifluoro-2-(3-trifluoromethylphenoxy)-6-etho...

Embodiment 3

[0050] The difference from Example 1 is that the positive active material is lithium iron phosphate (LiFePO 4 ) and lithium vanadium phosphate (LiVPO 4 ), the mass ratio of the two is 6:1; the negative electrode active material is simple silicon; the separator adopts a PP / PE / PP composite film with a thickness of 20 μm.

[0051] The electrolyte was prepared as follows:

[0052] The non-aqueous solvent propylene carbonate, ethyl methyl carbonate, 3,3-difluoropropionate methyl ester and tetrahydrofuran were mixed uniformly in a mass ratio of 2:10:0.5:0.5, allowed to stand for 30 minutes, and then added with a mass percentage of 4% and 5% 1,3-propane sultone and fluoroethylene carbonate, and then add lithium salt LiBOB to fully dissolve it, and make the concentration of lithium salt 1.3M. Finally, add 2,4,6-trifluoro-2-(3-trifluoromethylphenoxy)-4-chloro-6-methoxy-cyclotriphosphazene to make its mass percentage in the electrolyte The content is 20%, and the mixture is uniform, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com