Flame-proof sound-proof board and preparation thereof

A flame-retardant, sound-insulating board technology, applied in sound insulation, manufacturing tools, metal processing equipment, etc., can solve the problems of environmental re-pollution, long processing time, etc., and achieve the effect of low cost, simple operation, and solving potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

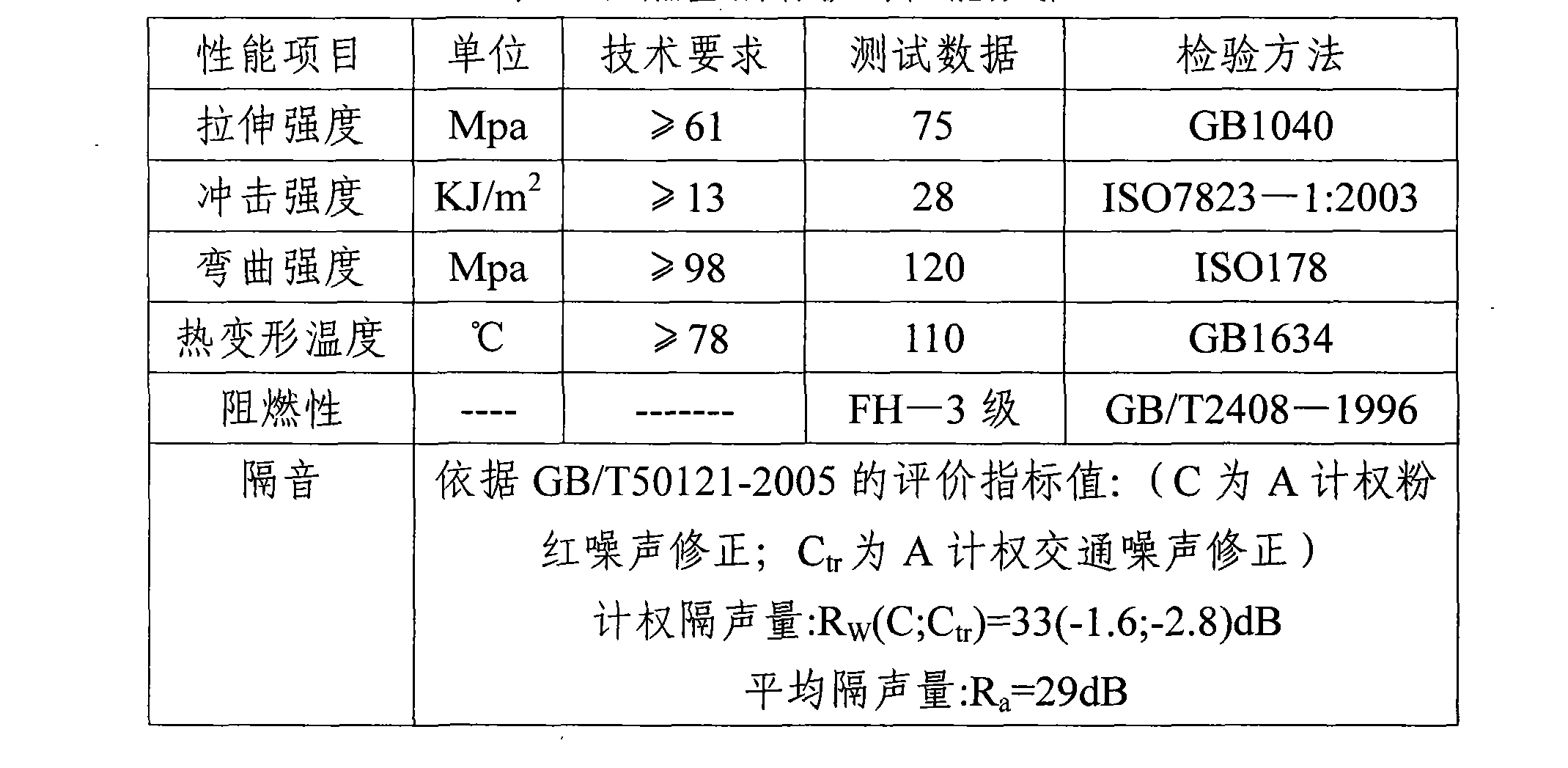

Embodiment 1

[0029] 1) Preparation of flame-retardant polymer materials

[0030] The composition and weight percentage of the flame-retardant polymer material of the present embodiment are:

[0031] Methyl methacrylate monomer 95.97%

[0032] Dimethyl methyl phosphate 3%

[0033] Azobisisobutyronitrile 0.3‰

[0034] 2-(2'-Hydroxy-5'-methylphenyl)benzotriazole 5‰

[0035] Bis(2,2,6,6-tetramethylpiperidinyl) sebacate 5‰

[0036] Stabilize methyl methacrylate monomer, flame retardant - dimethyl methyl phosphate, UV absorber - 2-(2'-hydroxy-5'-methylphenyl) benzotriazole, hindered amines Agent-bis(2,2,6,6-tetramethylpiperidinyl) sebacate was weighed according to the above ratio, added into a closed container with stirring, then added 0.06‰ initiator, heated to 80°C ~105°C, keep warm for 0.5-2 hours, cool down quickly after the viscosity of the polymerization solution reaches 100 centipoise to 500 centipoise; wait for the temperature of the polymerization solution to cool to 25°C-35°C, add...

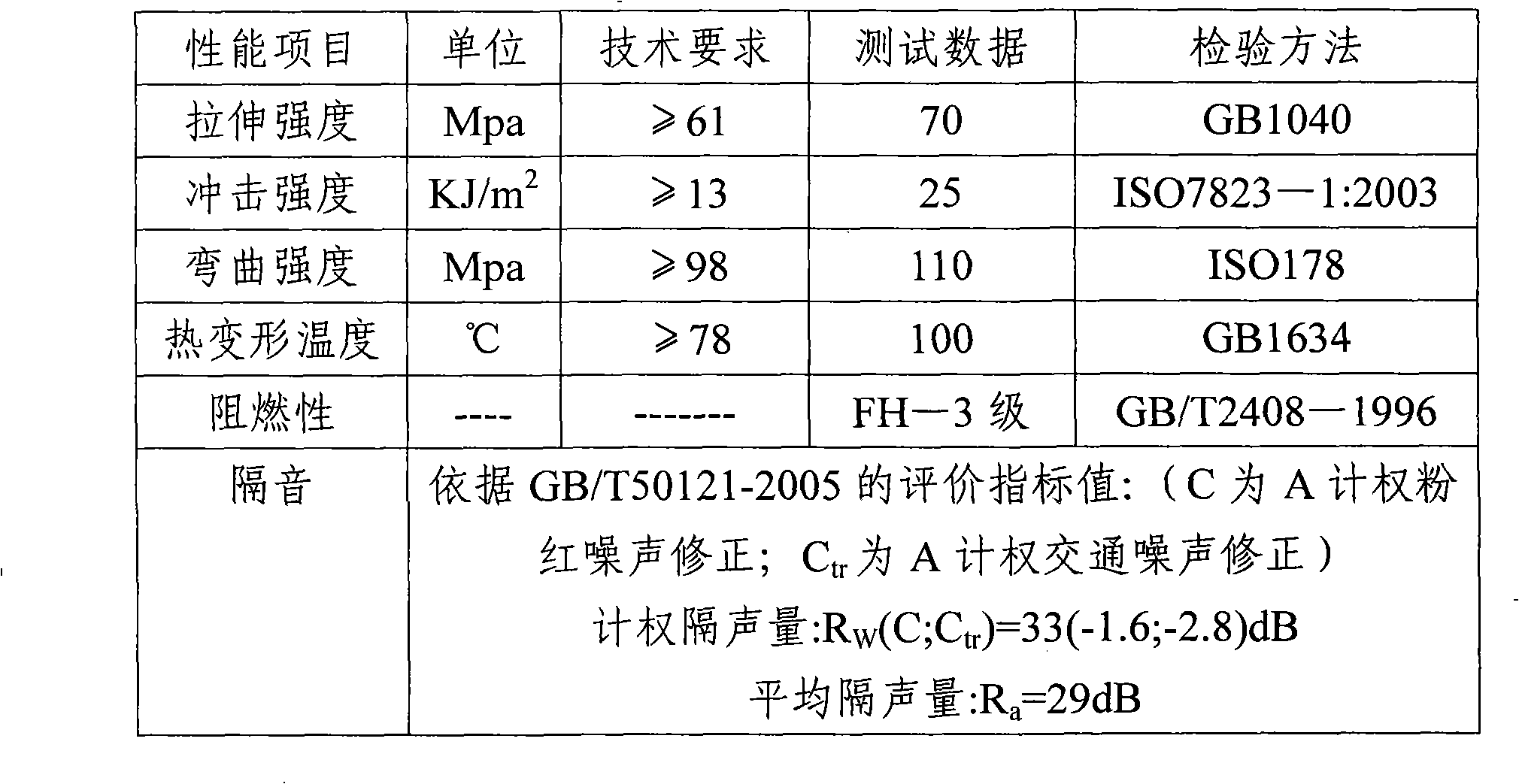

Embodiment 2

[0046] The composition and weight percentage of the flame-retardant polymer material of the present embodiment are:

[0047] Methyl methacrylate monomer 90.216%

[0048] Dimethyl Methyl Phosphate 9%

[0049] Azobisisobutyronitrile 0.24‰

[0050] 2-(2'-Hydroxy-5'-methylphenyl)benzotriazole 3.8‰

[0051] Bis(2,2,6,6-tetramethylpiperidinyl) sebacate 3.8‰

[0052] The preparation process of the flame-retardant polymer material of the present embodiment is:

[0053] Stabilize methyl methacrylate monomer, flame retardant - dimethyl methyl phosphate, UV absorber - 2-(2'-hydroxy-5'-methylphenyl) benzotriazole, hindered amines Agent-bis(2,2,6,6-tetramethylpiperidinyl) sebacate was weighed according to the above ratio, added to a closed container with stirring, then added 0.045‰ initiator, heated to 80°C ~105°C, keep warm for 0.5-2 hours, cool down quickly after the viscosity of the polymerization solution reaches 100 centipoise to 500 centipoise; wait for the temperature of the poly...

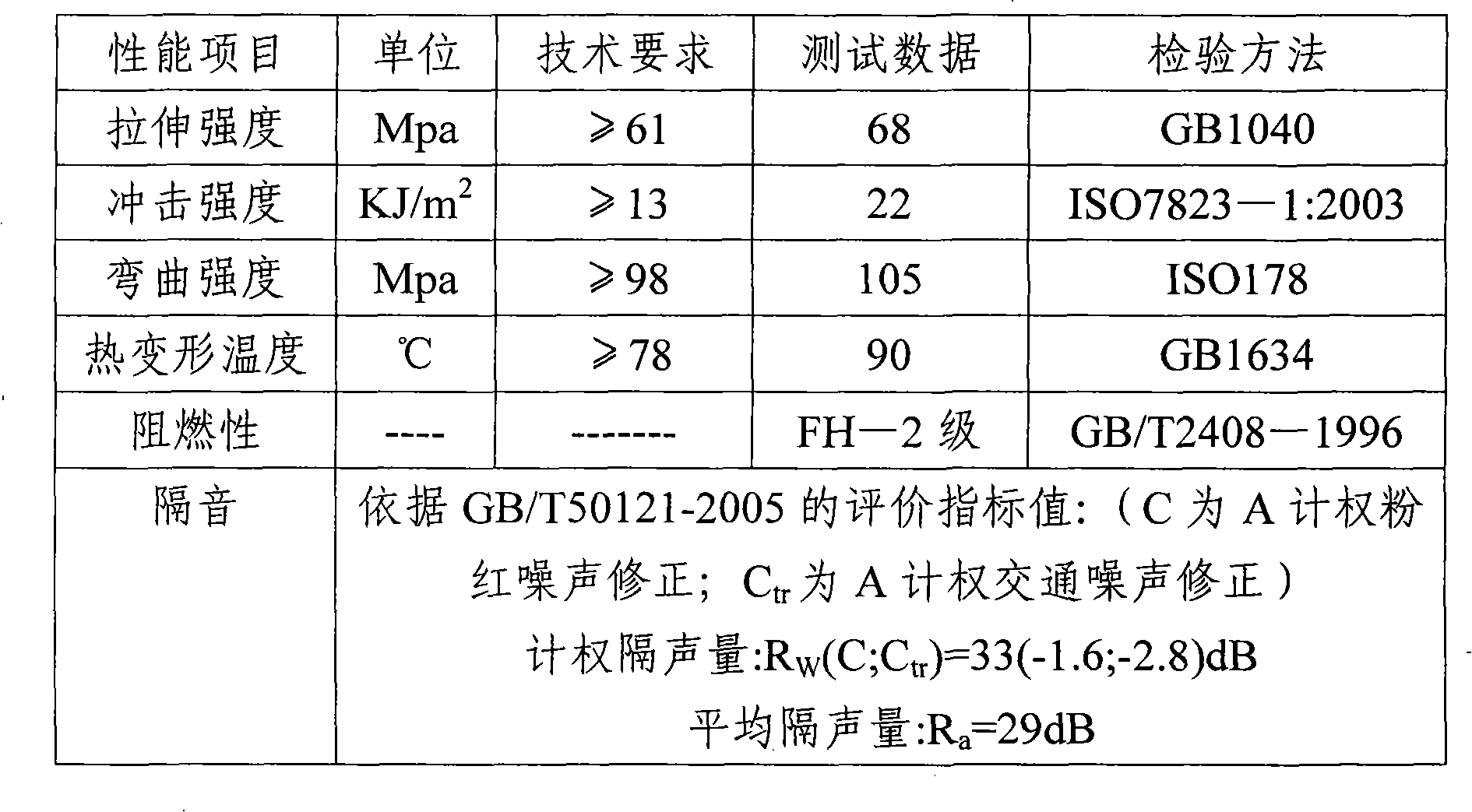

Embodiment 3

[0059] The composition and weight percentage of the flame-retardant polymer material of the present embodiment are:

[0060] Methyl methacrylate monomer 83.462%

[0061] Dimethyl Methyl Phosphate 16%

[0062] Azobisisobutyronitrile 0.18‰

[0063] 2-(2'-Hydroxy-5'-methylphenyl)benzotriazole 2.6‰

[0064] Bis(2,2,6,6-tetramethylpiperidinyl) sebacate 2.6‰

[0065] The preparation process of the flame-retardant polymer material of the present embodiment is:

[0066] Stabilize methyl methacrylate monomer, flame retardant - dimethyl methyl phosphate, UV absorber - 2-(2'-hydroxy-5'-methylphenyl) benzotriazole, hindered amines Agent-bis(2,2,6,6-tetramethylpiperidinyl) sebacate was weighed according to the above ratio, added into a closed container with stirring, then added 0.03‰ initiator, heated to 80°C ~105°C, keep warm for 0.5-2 hours, cool down quickly after the viscosity of the polymerization solution reaches 100 centipoise to 500 centipoise; wait for the temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com