High-strength heat-resistant casting aluminum-silicon alloy for engine piston

A heat-resistant aluminum and engine technology, used in engine components, machines/engines, pistons, etc., can solve the problems of difficult mass production of materials, and achieve the effect of improving creep resistance, good mechanical properties at room temperature, and meeting the requirements of high temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Aluminum silicon alloy composition: Si 15.0%, Cu 4.5%, Mg 1.2%, Mn 0.2%, Ni 3%, Zr 0.3%, Ti0.2%, Hf 0.5%, Sc 0.2%, the balance is Al and unavoidable Impurities.

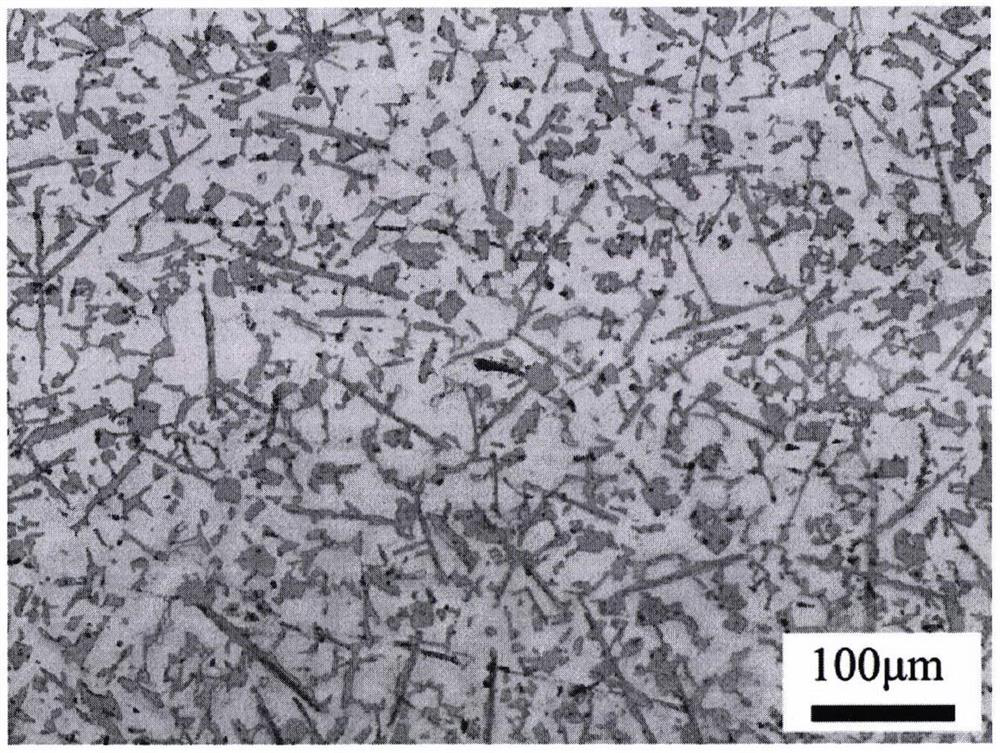

[0028] microstructure: figure 1 For the microstructure of the aluminum alloy piston material in this embodiment, the particle size and distribution of the primary silicon are uniform, and the particle size is generally between 30-60 μm; the length of the needle-shaped heat-resistant phase is between 60-150 μm.

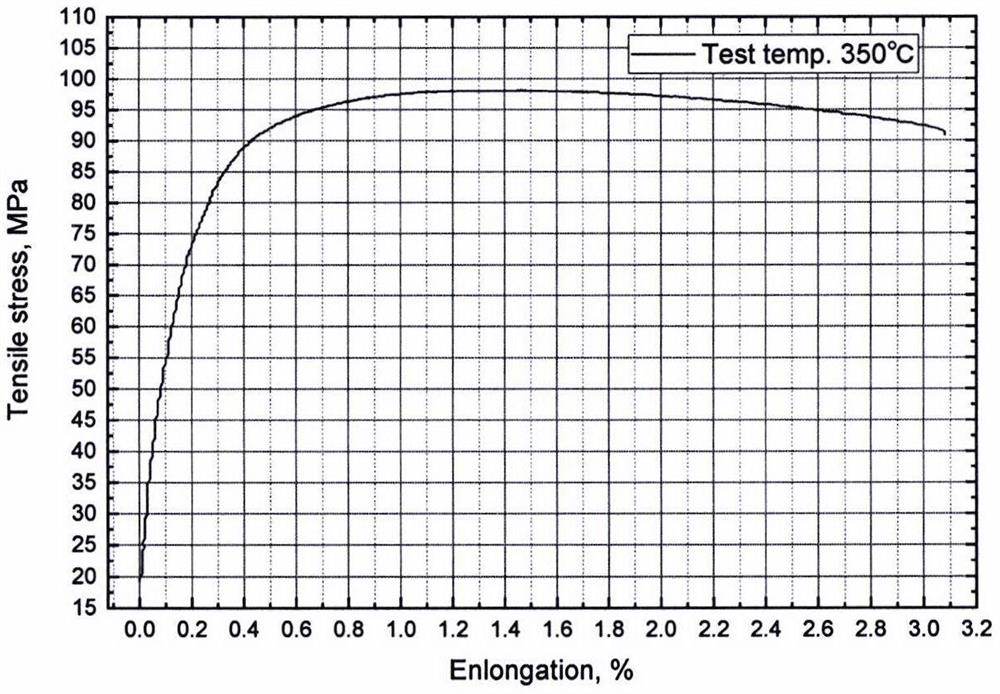

[0029]Mechanical properties: the tensile strength at room temperature is 320MPa, the elongation after fracture is about 2.0%, and the tensile strength and elongation after fracture at 350°C are 98MPa and 2.9% respectively (see figure 2 )

Embodiment 2

[0031] Aluminum silicon alloy composition: Si 13.5%, Cu 4.0%, Mg 1.2%, Mn 0.2%, Ni 4%, Zr 0.40%, Ti0.30%, Er 0.2%, Nd 0.3%, the balance is Al and unavoidable Impurities.

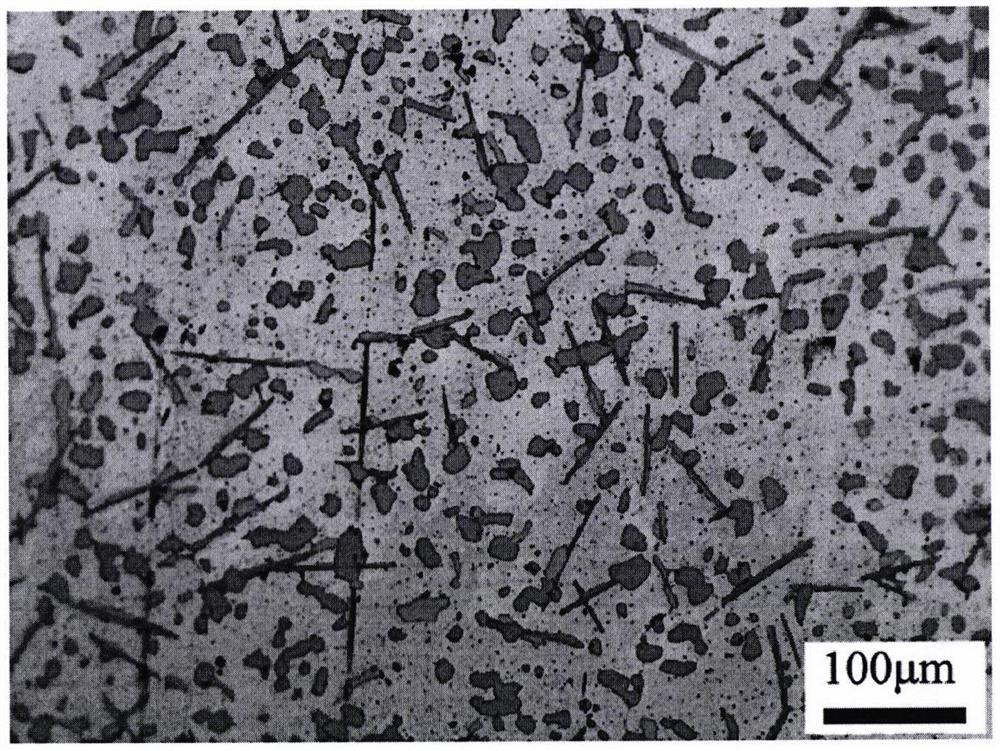

[0032] microstructure: image 3 It is the microstructure after solution aging of the aluminum alloy piston material of this embodiment. Compared with the as-cast aluminum-silicon alloy, the primary silicon is slightly refined and the corners are spheroidized, the needle-shaped heat-resistant phase does not change significantly, and the eutectic silicon appears as tiny particles due to back-dissolving precipitation.

[0033] Mechanical properties: the tensile strength at room temperature is 295MPa, the elongation after fracture is about 1.5%, and the tensile strength and elongation after fracture at 350°C are 93MPa and 2.1% respectively

Embodiment 3

[0035] Aluminum silicon alloy composition: Si 13.5%, Cu 3.5%, Mg 1.0%, Mn 0.2%, Ni 3.8%, Zr 0.33%, Ti 0.2%, Hf0.4%, Nb 0.3%, the balance is Al and unavoidable Impurities.

[0036] microstructure: Figure 4 It is the scanning electron microscope structure of the aluminum alloy piston material of this embodiment. After high-temperature solution treatment, evenly distributed spherical nanoscale Al 3 Zr-type precipitated particles, the size of which is generally 50nm.

[0037] Mechanical properties: 425°C high temperature tensile strength and elongation after fracture are 59MPa and 27% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com