Corrosion-resistant super austenitic stainless steel and manufacturing technique thereof

A technology of austenitic stainless steel and manufacturing process, applied in the field of corrosion-resistant super austenitic stainless steel and its manufacturing process, can solve problems such as low strength, and achieve the effects of improving alloy life, excellent corrosion resistance, and good mechanical properties at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

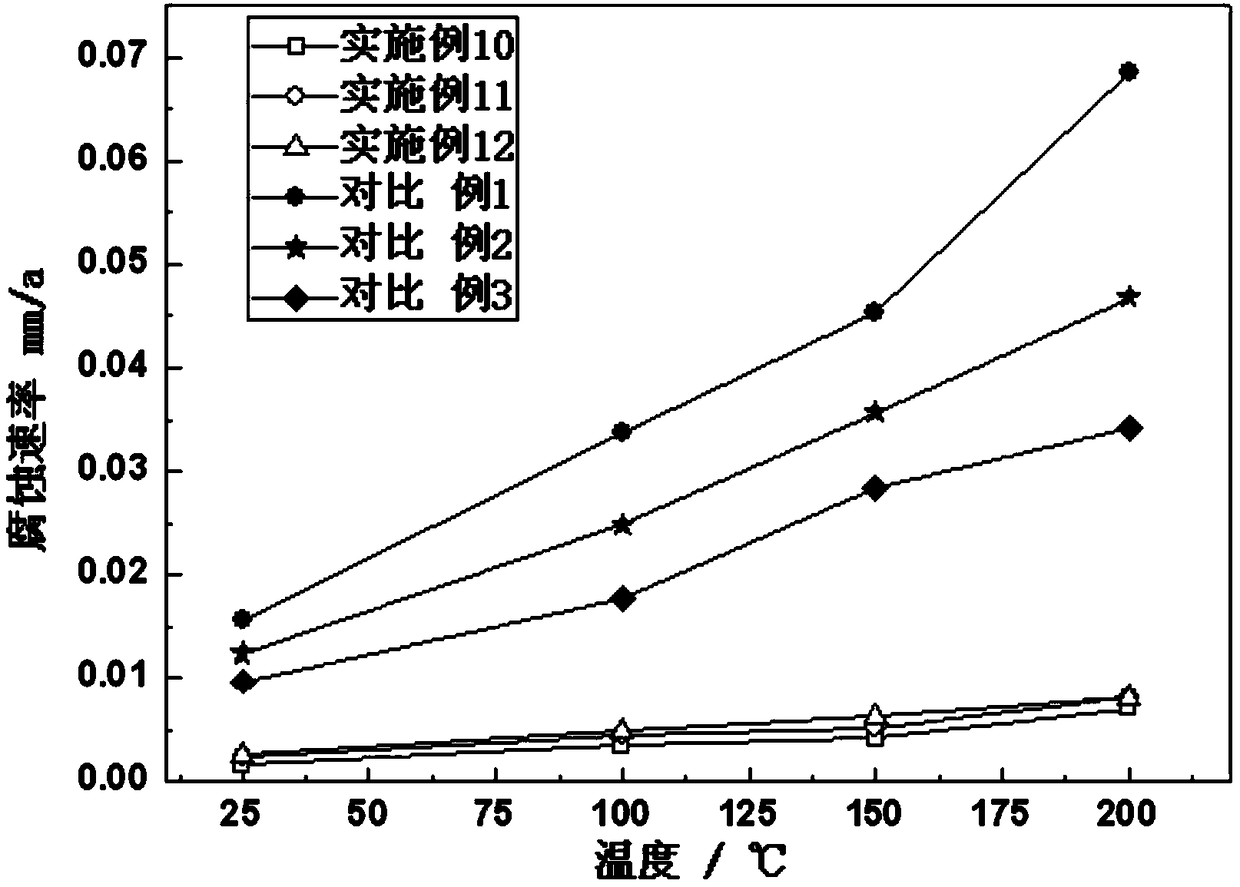

Examples

Embodiment 1-14

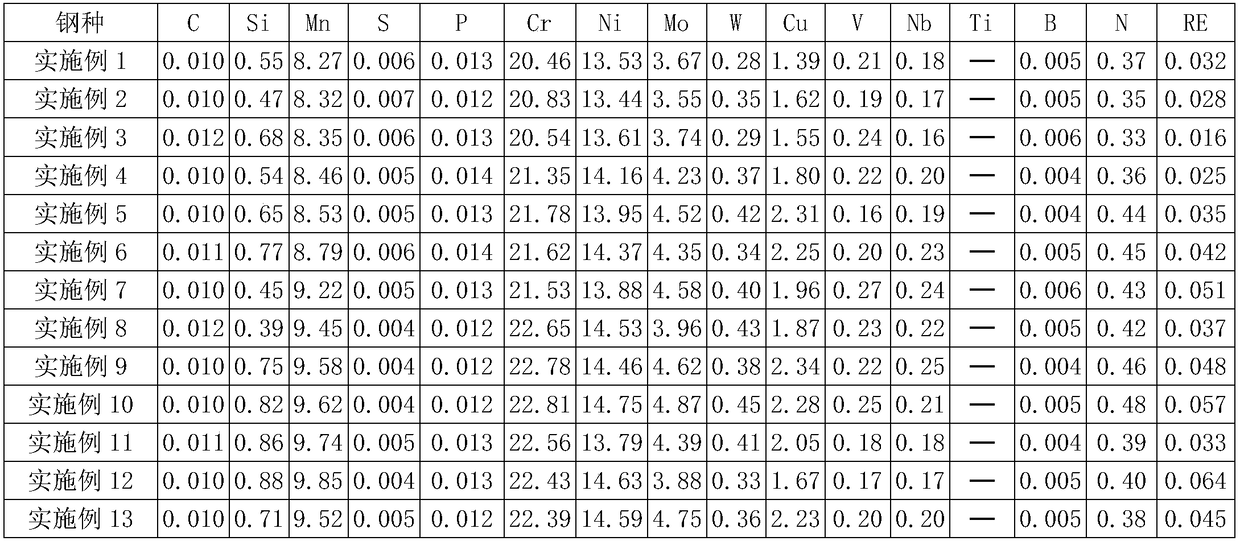

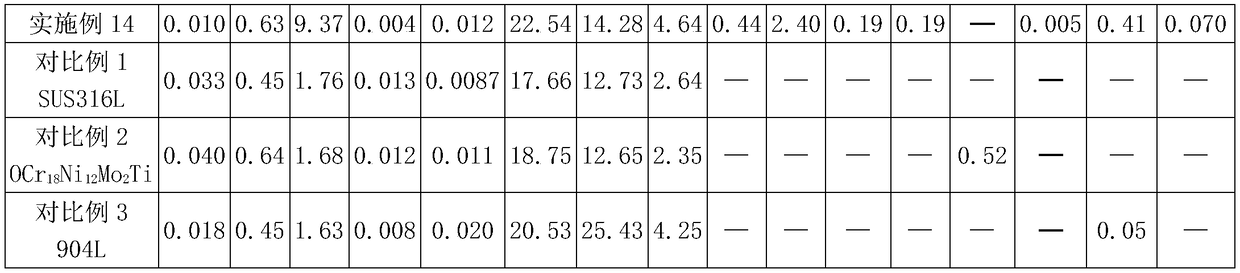

[0030] The composition of the super austenitic stainless steel in Examples 1-14 is shown in Table 1. The specific processing technology of stainless steel is as follows:

[0031] (1) Smelting: use any one of vacuum induction furnace, electric furnace and out-of-furnace refining, converter and out-of-furnace refining to smelt other components except rare earth elements, add rare earth elements before tapping and casting, and control the casting temperature at 1500 -1650°C;

[0032] (2) Ingot casting or ingot billet opening: Forging billet opening or continuous casting and rolling is adopted, the heating temperature is 1100-1250 °C, the initial forging temperature of billet opening is controlled at 1050-1150 °C, and the final forging temperature is controlled at 950-1050 °C ;

[0033] (3) Hot rolling: the billet heating temperature is 1100-1250°C, the starting rolling temperature is controlled at 1050-1150°C, and the final rolling temperature is controlled at 950-1050°C;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pitting potential | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com