ZSA-3 titanium alloy pipe, and preparation method and application thereof

A titanium alloy tube, ZSA-3 technology, applied in the field of titanium alloy preparation, can solve the problems of difficult to meet the bottom hole temperature, pressure and corrosion working conditions, insufficient high temperature corrosion resistance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

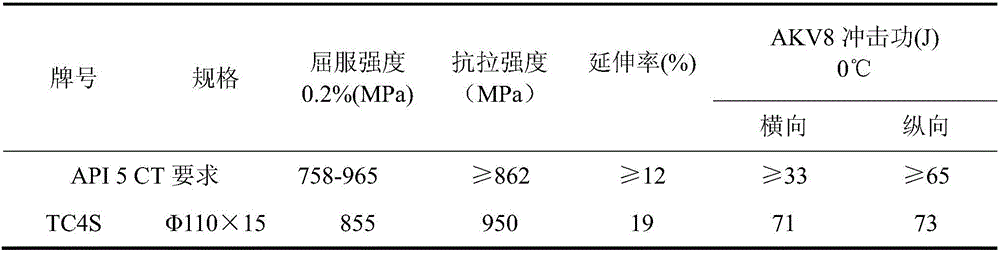

Examples

Embodiment 1

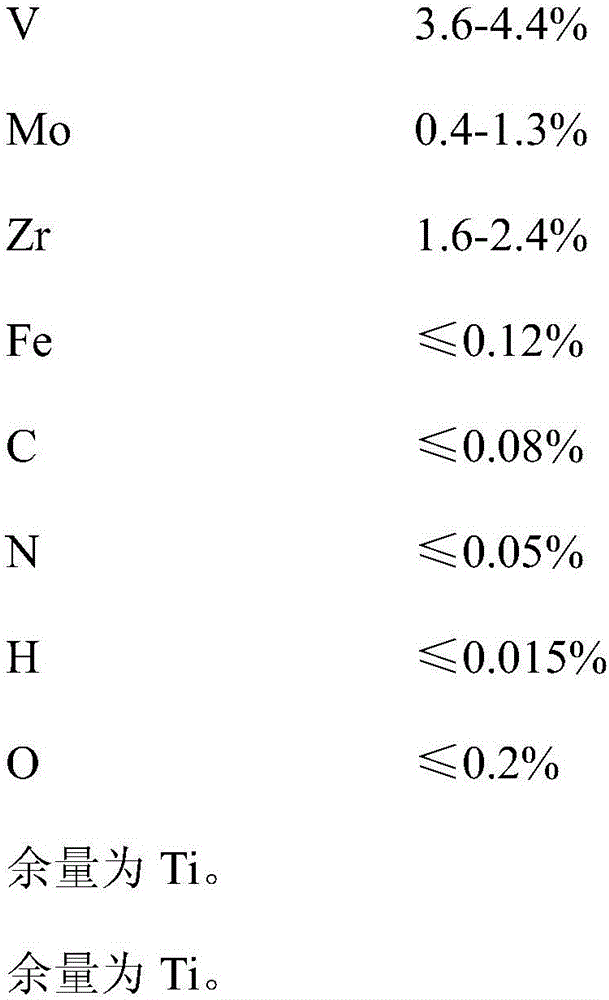

[0067] Dosing according to the following components: Al 4.6%, V 3.6%, Mo 0.4%, Zr 1.6%, Fe 0.05%, C0.03%, N 0.01%, H 0.008%, O 0.07%, and the balance is Ti; Then, it is smelted in a vacuum consumable electrode arc furnace. The smelting temperature is 1680 ° C. It is cooled by cooling circulating water while melting. After smelting, it is cooled for 90 minutes to obtain alloy ingots; the alloy ingots are forged into bars and then machined. After the bar is released from the furnace, it is pierced with a skew rolling piercer, and the piercing speed is 15mm per second; after the tube blank is repaired, it is rolled, The rolling speed is 20 times per minute, the feeding amount is 3 mm each time, and the rolling passes from the billet to the finished pipe are 5 passes to obtain the finished pipe; the finished pipe is normalized, and the normalizing temperature is 850 ℃ , the holding time is 90min, after air cooling, tempering treatment is carried out, the tempering temperature is 6...

Embodiment 2

[0069] The ingredients are as follows: Al 5.2%, V 4%, Mo 1%, Zr 2%, Fe 0.085%, C 0.055%, N 0.03%, H 0.011%, O 0.13%, and the balance is Ti; The smelting was carried out in a vacuum consumable electrode arc furnace at a smelting temperature of 2300°C, which was cooled by cooling circulating water while melting. After smelting, it was cooled for 135 minutes to obtain an alloy ingot; the alloy ingot was forged into a bar and machined into After the bar is released from the furnace, it is pierced with a skew rolling piercer, and the piercing speed is 40mm per second; after the tube blank is repaired, it is rolled and rolled. The manufacturing speed is 35 times per minute, the feeding amount is 4mm each time, and the rolling passes from the billet to the finished pipe are 3 passes to obtain the finished pipe; the finished pipe is normalized, and the normalizing temperature is 800 ℃, The holding time is 60 min, and after air cooling, tempering treatment is performed. The tempering t...

Embodiment 3

[0071]Dosing according to the following components: Al 5.4%, V 4.4%, Mo 1.3%, Zr 2.4%, Fe 0.12%, C0.08%, N 0.05%, H 0.015%, O 0.2%, and the balance is Ti; Then, it is smelted in a vacuum consumable electrode arc furnace. The smelting temperature is 3000 ℃, and it is cooled by cooling circulating water while melting. After smelting, it is cooled for 180 minutes to obtain an alloy ingot; the alloy ingot is forged and then machined. After the bar is released from the furnace, it is pierced with a skew rolling piercing machine, and the piercing speed is 60mm per second; after the tube blank is repaired, it is rolled, The rolling speed is 50 times per minute, the feeding amount is 6 mm each time, and the rolling passes from the billet to the finished pipe are 2 passes to obtain the finished pipe; the finished pipe is normalized, and the normalizing temperature is 750 ℃ , the holding time is 45min, after air cooling, tempering treatment is carried out, the tempering temperature is 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com