Hard alloy using iron-aluminum intermetallic compound as bonding phase and preparation method thereof

A technology of cemented carbide and aluminum metal, applied in the field of cemented carbide materials and its preparation, can solve the problems of coarse powder, low mechanical properties of alloy at room temperature, and easy brittle fracture, etc., and achieve uniform composition, simple preparation method and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

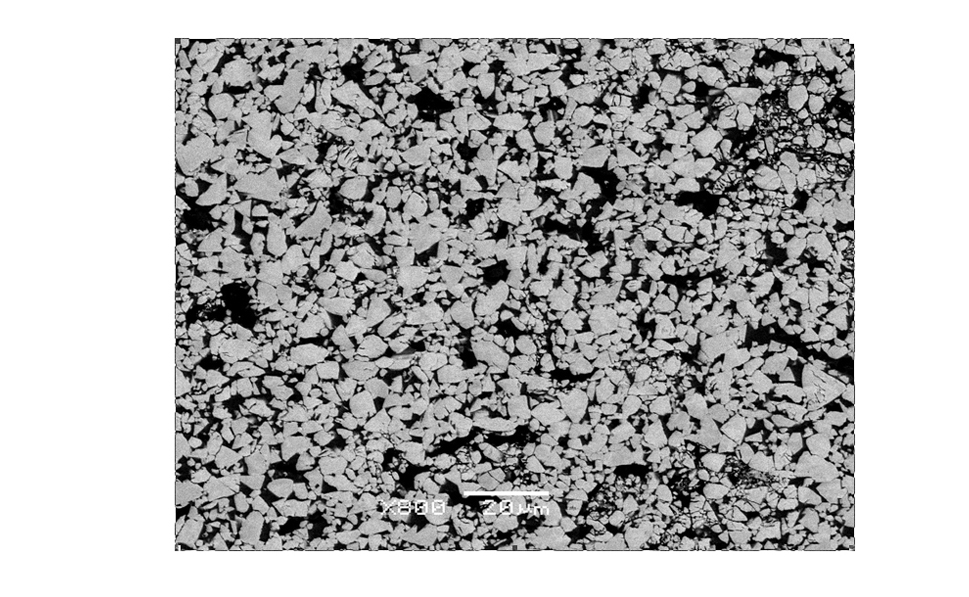

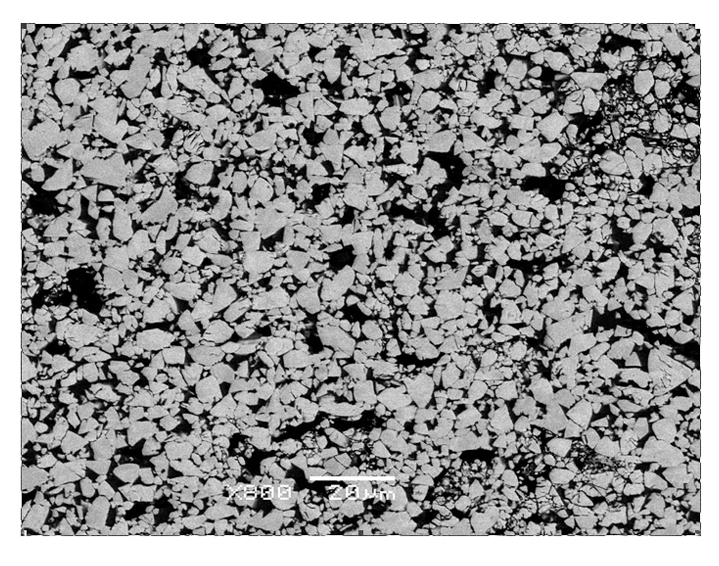

[0012] Embodiment 1: press the composition of iron-aluminum intermetallic compound FeAl, the iron-aluminum intermetallic compound Fe that mass percentage is 1.69% 2 al 5 The pre-alloyed powder and 2.10% iron powder are ball milled and mixed with the remaining tungsten carbide powder for 18 hours to obtain a ball-milled mixture; the ball-milled mixture is prepared into a uniform mixture powder by spray drying, and then pressed into shape; the compact is sintered During the process, heat preservation at 1200°C±20°C for 1 hour under vacuum conditions, and then sinter at 1350°C in a low-pressure liquid phase to obtain a cemented carbide with iron-aluminum intermetallic compound FeAl as the binder phase, in which FeAl The volume percentage is 10%. The scanning electron microscope photo of the cemented carbide is shown in figure 1 , see Table 1 for details.

Embodiment 2

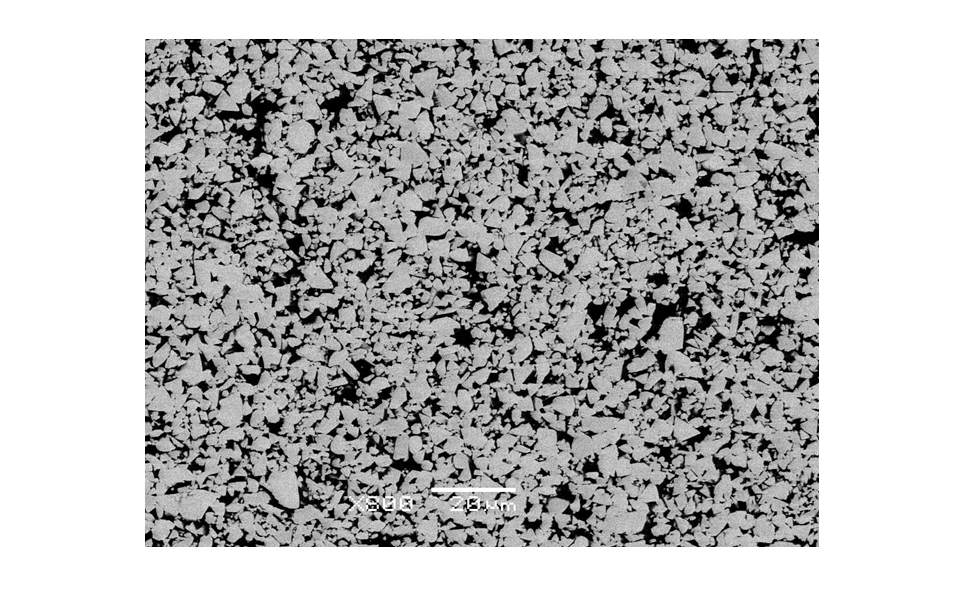

[0013] Embodiment 2: Press iron-aluminum intermetallic compound Fe 3 The composition of Al, the mass percentage is 1.31% iron-aluminum intermetallic compound Fe 2 al 5 The pre-alloyed powder and 3.23% iron powder are ball milled and mixed with the remaining tungsten carbide powder. Except that the low-pressure liquid phase sintering temperature is 1550 ° C, the rest of the process steps, conditions and parameters are the same as in Example 1. The obtained iron- — Aluminum intermetallic compound Fe 3 Al is the cemented carbide of the binder phase, where Fe 3 The volume percentage of Al is 10%. The scanning electron microscope photo of the cemented carbide is shown in figure 2 , see Table 1 for details.

Embodiment 3

[0014] Embodiment 3: press the composition of iron-aluminum intermetallic compound FeAl, the iron-aluminum intermetallic compound Fe that mass percent is 3.62% 2 al 5 The pre-alloyed powder and 4.51% iron powder are ball milled and mixed with the remaining tungsten carbide powder for 24 hours to obtain a ball-milled mixture; the ball-milled mixture is spray-dried to prepare a uniform mixture powder, and then pressed into shape; the compact is sintered During the process, heat preservation at 1200°C±20°C and vacuum for 1 hour, and then sinter at 1320°C in a low-pressure liquid phase to obtain a cemented carbide with iron-aluminum intermetallic compound FeAl as the binder phase, of which FeAl The volume percentage is 20%. The scanning electron microscope photo of the cemented carbide is shown in figure 1 , see Table 1 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com