Alloy with excellent room-temperature soft magnetic property and mechanical property, and preparation method thereof

A soft magnetic alloy and alloy technology, applied in the direction of magnetic objects, magnetic materials, electrical components, etc., can solve the problem that the soft magnetic properties and mechanical properties of FeCoV-based soft magnetic alloys are not well compatible, so as to facilitate the preparation of larger sizes, Simple preparation process and excellent mechanical properties at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a kind of preparation method of described FeCoVCr soft magnetic alloy, concrete steps are:

[0029] The first step is to select raw materials for proportioning melting, and the melting method is vacuum electric arc furnace melting and argon protection. The raw material ratio is Fe-49Co-2V-xCr, 0<x≤1.0, and the above are atomic percentages.

[0030] The second step is to carry out vacuum diffusion annealing on the smelted alloy, the temperature is ≥900°C, the annealing time is 2-10 hours, and the molten ingot is cooled with the furnace.

[0031] The third step is high-temperature forging, which can eliminate defects such as looseness of the alloy during the smelting process and optimize the microstructure. High temperature forging temperature ≥ 800 ℃.

[0032] In the fourth step, the block material obtained after the high-temperature forging in the third step is subjected to hot rolling for more than three consecutive passes, and the...

Embodiment 1

[0037] Adopt preparation method provided by the invention to prepare Fe-49Co-2V-0.5Cr alloy, concrete steps are as follows:

[0038] The first step is the ratio of raw materials and smelting.

[0039] Take Fe with a purity of 99.99% and Co, V, and Cr with a purity of 99.9% according to the atomic percentage of Fe-49Co-2V-0.5Cr, and conduct arc melting under argon protection. To ensure homogenization, the raw material was remelted 5 times with negligible mass loss.

[0040] The second step is annealing.

[0041] After diffusion annealing at a temperature of 1200°C for 4 hours in vacuum, the alloy was cooled with the furnace.

[0042] The third step is high temperature forging.

[0043] The annealed molten ingot is forged, the forging temperature is 1150° C., and the thickness of the alloy block after forging is 6 mm.

[0044] The fourth step is hot rolling.

[0045] After the block material in the third step is kept at 1000° C. for 1 hour, it is hot-rolled to a thickness of ...

Embodiment 2

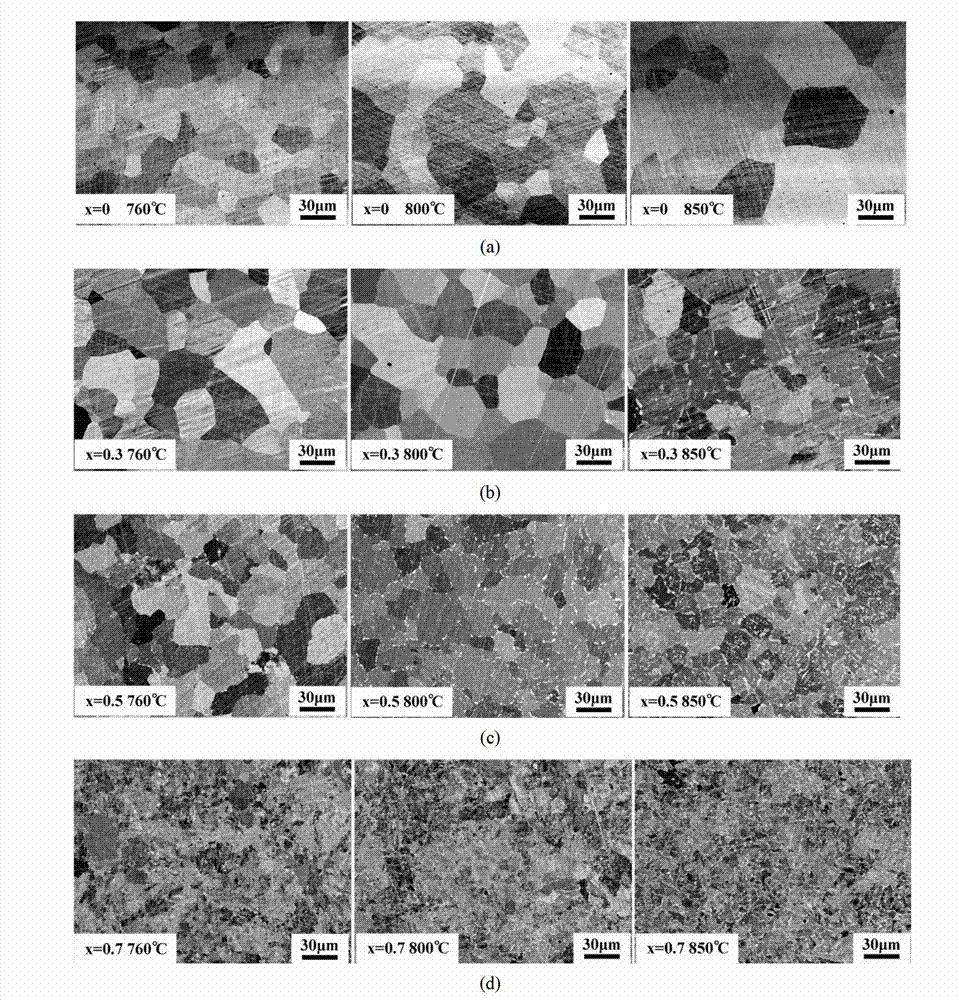

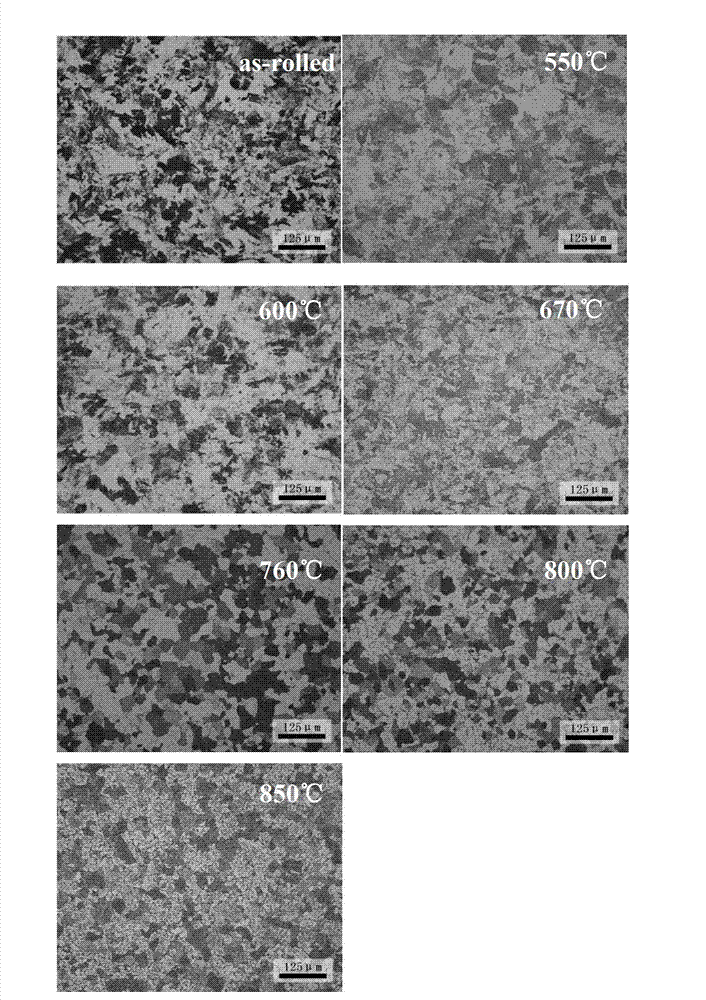

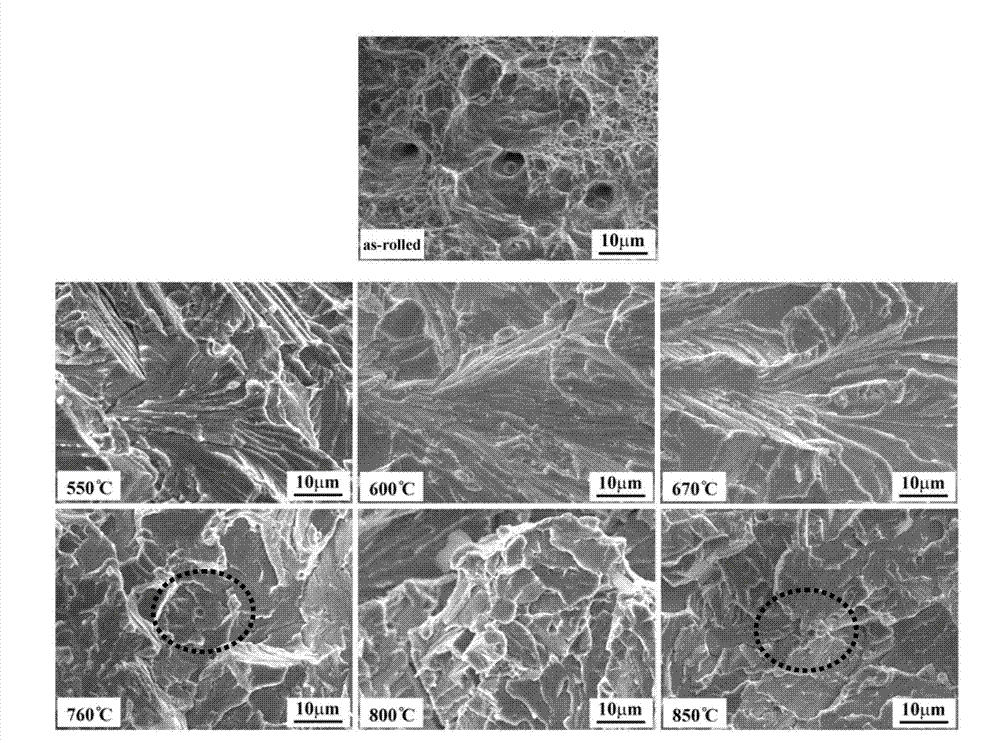

[0057] Adopting the method provided by the present invention to prepare Fe-49Co-2V-0.3Cr soft magnetic alloy material, the specific process steps are as follows:

[0058] Fe with a purity of 99.99% and Co, V, and Cr with a purity of 99.9% are proportioned according to the atomic percentage of Fe-49Co-2V-0.3Cr, and are arc smelted under argon protection. To ensure homogenization, the raw material was remelted 5 times with negligible mass loss. Next, after diffusion annealing in vacuum at 1200°C for 4h, the alloy is cooled with the furnace. After that, the molten ingot was forged, the forging temperature was 1150° C., and the thickness after forging was 10 mm. After that, heat-retain at 1000° C. for 1 hour and then hot-roll to 3 mm. After that, cold rolling processing with a deformation amount of 30% was performed. The cold-rolled alloy sheet was subjected to vacuum final heat treatment at different temperatures for 2 hours. The final heat treatment temperatures were 550°C, 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com