Method for preparing carbon-fiber-toughened alumina ceramic material

An alumina ceramic and carbon fiber technology, applied in the field of ceramic materials, can solve the problems of high brittleness and low toughness of pure alumina, and achieve the effects of high densification, improved strength and toughness, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

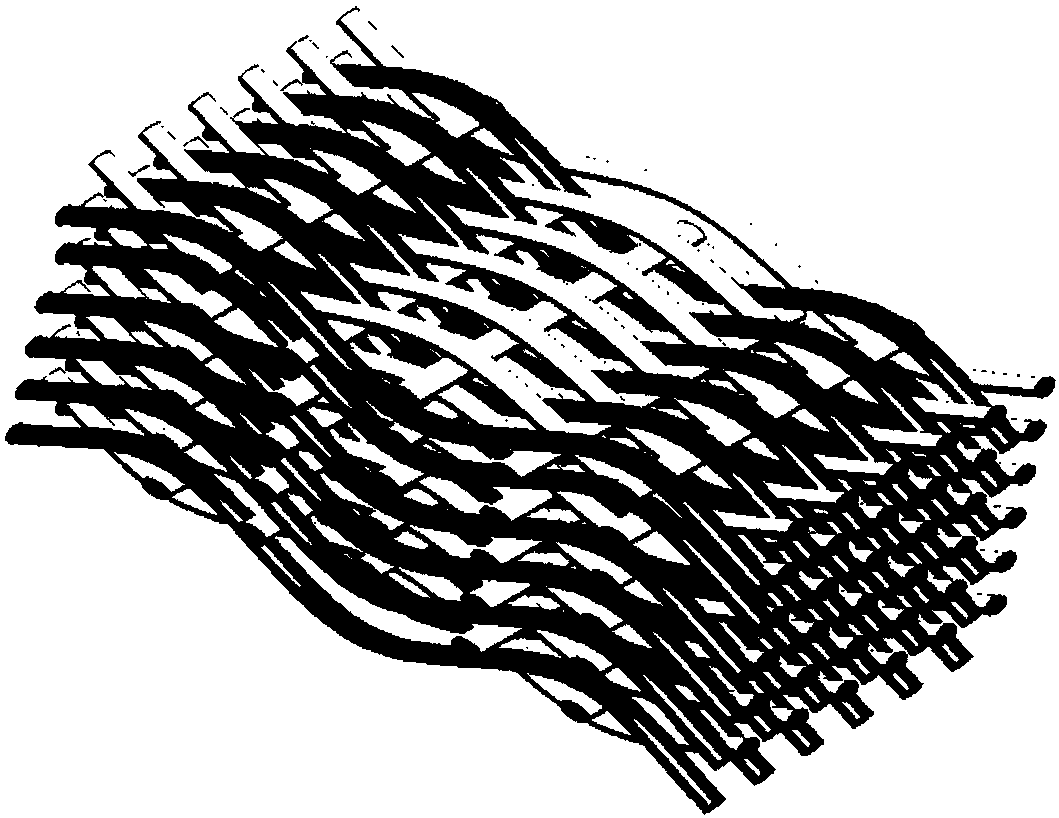

Image

Examples

Embodiment 1

[0015] Embodiment 1: The raw materials are prepared according to the volume percentage of 85% alumina and 15% 2.5D woven carbon fiber; the weighed alumina is planetary reinforced ball milled for 180 h with deionized water as the medium and alumina as the ball. The surface pretreatment of 2.5D woven carbon fiber is carried out by low-temperature surface oxidation process. The process is as follows: the spray pressure is 0.1MPa, the hot air temperature at the inlet of the dryer is 380±30°C, the outlet temperature is 100±5°C, and the feed rate is 12±2ml / min, the nozzle diameter is 1.0mm; 2.5D woven carbon fiber is fixed in the graphite mold at four points with a small amount of 502 binder, evenly sieved into the ball-milled alumina powder, pre-pressed, and hot-pressed and sintered in vacuum The sintering temperature is 1500°C, the sintering pressure is 30MPa, and the sintering holding time is 30min; the sintered alumina / 2.5D woven carbon fiber ceramic material has a Vickers hardn...

Embodiment 2

[0016] Embodiment 2: Others are the same as in Embodiment 1, except that the raw materials are prepared according to the volume percentage of 92% alumina and 8% 2.5D woven carbon fiber; the sintering temperature is 1550°C, the sintering pressure is 35MPa, and the sintering holding time is 35min; The alumina / 2.5D woven carbon fiber ceramic material has a Vickers hardness of 18.1~19.3GPa, a bending strength of 580~600MPa, and a fracture toughness of 5.0~5.8MPa m 1 / 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com