High-strength corrosion-resistant wrought magnesium alloy and preparing method thereof

A deformed magnesium alloy and corrosion-resistant technology, applied in the field of metal materials, can solve problems such as insufficient mechanical properties and corrosion resistance, achieve good low-temperature forming ability, improve corrosion resistance, and enhance the effect of solid solution strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

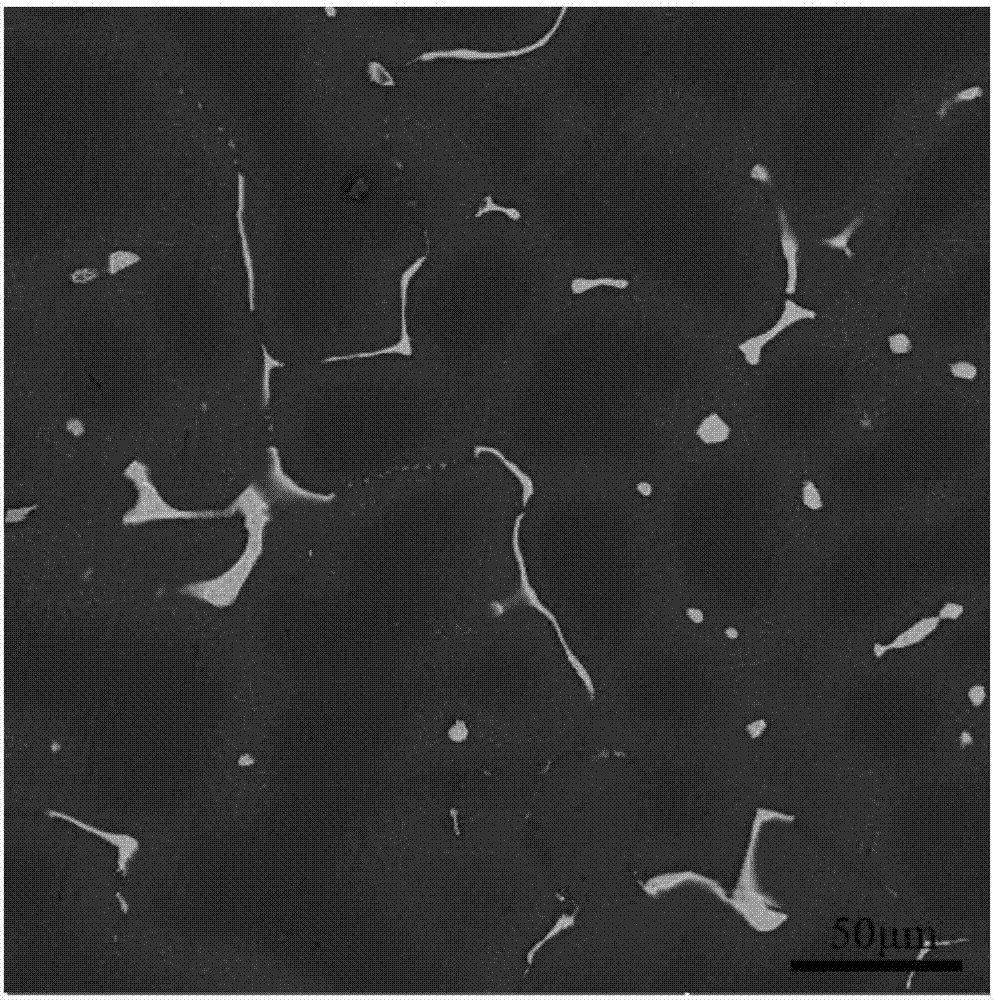

[0030] Preparation of a High-Strength Corrosion-Resistant Deformable Magnesium Alloy

[0031] (1) A high-strength corrosion-resistant deformation magnesium alloy, which comprises the following components by mass percentage: Sn: 7.9wt.%, Zn: 1.9wt.%, Mn: 0.4wt.%, Ca: 0wt.%, Na : 0.06wt.%, the total amount of unavoidable Fe, Ni, Si impurities is less than 0.03%, and the rest is Mg. Using pure magnesium ingots, pure tin ingots, pure zinc ingots, magnesium-manganese master alloys, magnesium-calcium master alloys and metal sodium as raw materials, after mechanical grinding to remove scale, the ingredients are calculated according to the mass percentage of the magnesium alloy components;

[0032](2) Put the pure magnesium ingot into the low-carbon steel melting crucible of the smelting furnace until the pure magnesium ingot is melted, and when the temperature of the magnesium melt rises to 720°C, the pure zinc ingot and the pure Tin ingots are added to the magnesium melt until the ...

Embodiment 2

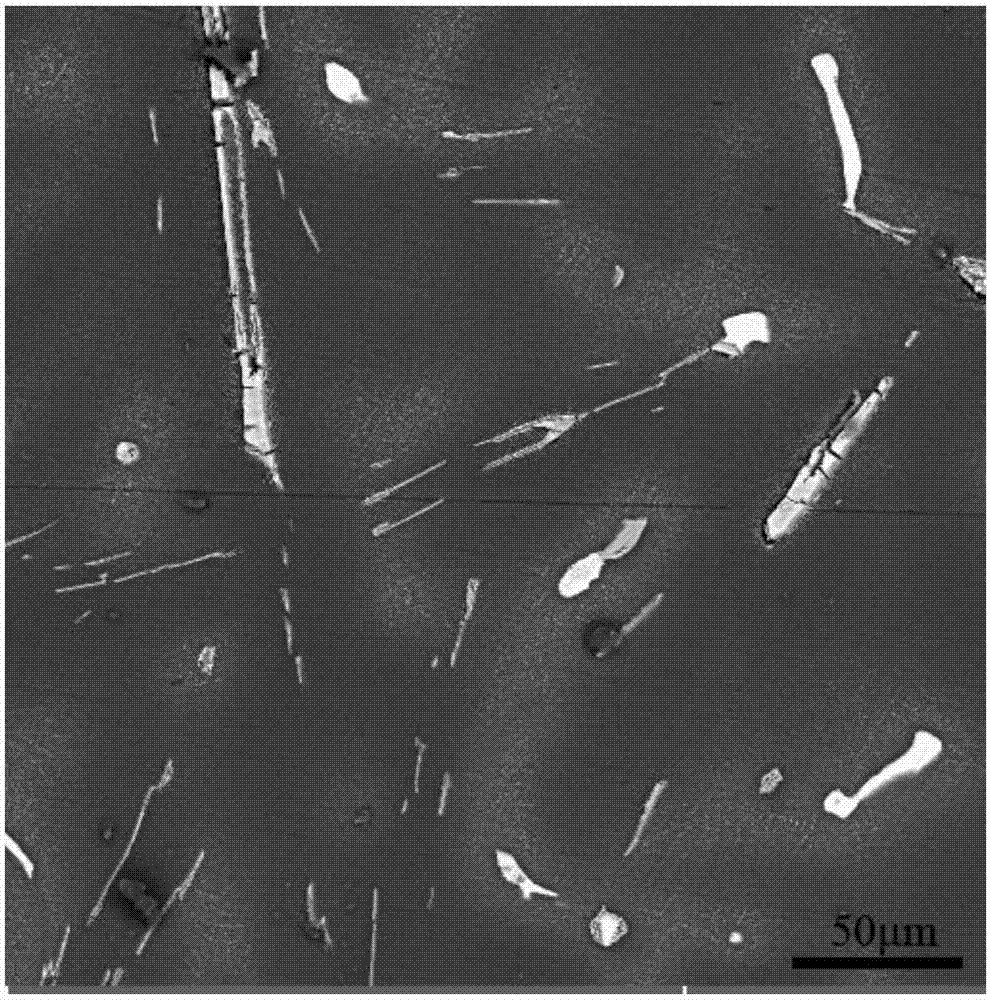

[0037] Preparation of a High-Strength Corrosion-Resistant Deformable Magnesium Alloy

[0038] (1) A high-strength, corrosion-resistant and deformable magnesium alloy, comprising the following components by mass percentage: Sn: 8.1wt.%, Zn: 2.4wt.%, Mn: 0.3wt.%, Ca: 0.2wt.%, Na: 0.08wt.%, the total amount of unavoidable Fe, Ni, Si impurities is less than 0.03%, and the rest is Mg. Using pure magnesium ingots, pure tin ingots, pure zinc ingots, magnesium-manganese master alloys, magnesium-calcium master alloys and metal sodium as raw materials, after mechanical grinding to remove scale, the ingredients are calculated according to the mass percentage of the magnesium alloy components;

[0039] Steps (2)-(4) are as in Example 1.

Embodiment 3

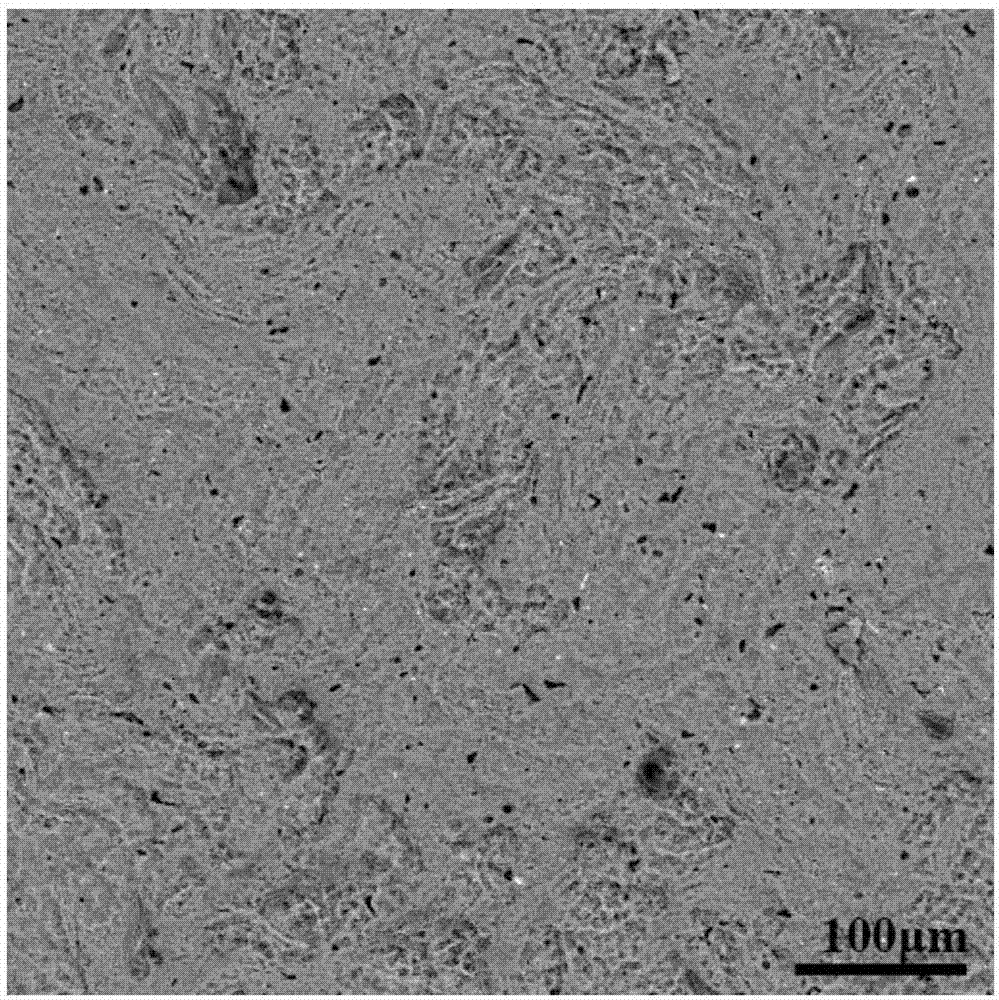

[0041] Preparation of a High-Strength Corrosion-Resistant Deformable Magnesium Alloy

[0042] (1) A high-strength corrosion-resistant deformation magnesium alloy, which comprises the following components by mass percentage: Sn: 7.6wt.%, Zn: 2.0wt.%, Mn: 0.6wt.%, Ca: 0.5wt.%, Na: 0.07wt.%, the total amount of unavoidable Fe, Ni, Si impurities is less than 0.03%, and the rest is Mg. Using pure magnesium ingots, pure tin ingots, pure zinc ingots, magnesium-manganese master alloys, magnesium-calcium master alloys and metal sodium as raw materials, after mechanical grinding to remove scale, the ingredients are calculated according to the mass percentage of the magnesium alloy components;

[0043] Steps (2)-(4) are as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com