High-zinc deformation magnesium alloy and preparation and processing method thereof

A technology of wrought magnesium alloys and magnesium alloys, which is applied in the field of high-zinc wrought magnesium alloys and their preparation, and industrial wrought magnesium alloys, which can solve the problems of brittle fracture of alloys, decreased grain boundary mobility, and limited impact resistance of rare earth magnesium alloys. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

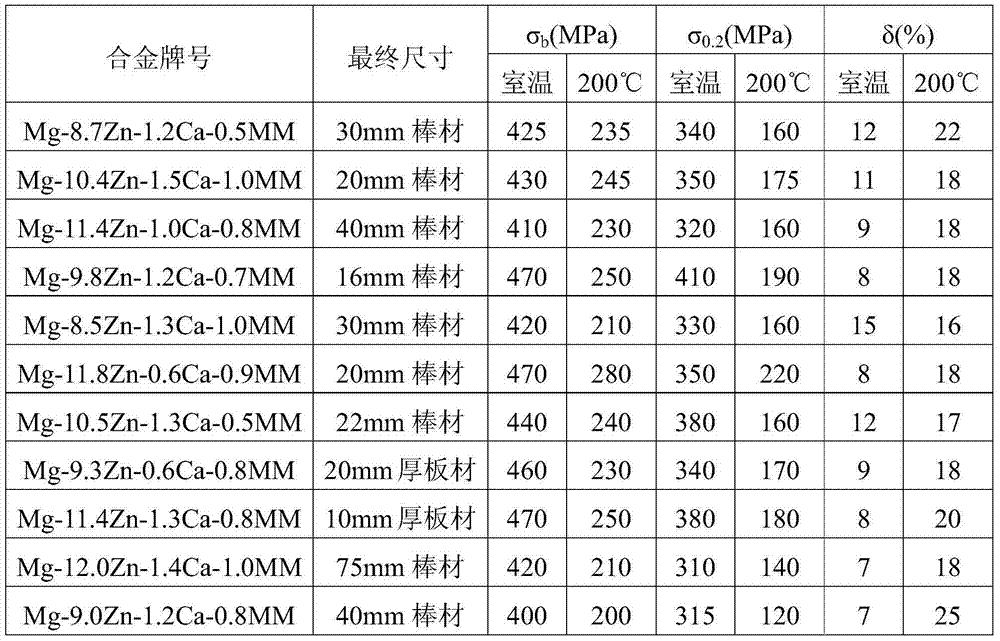

Examples

preparation example Construction

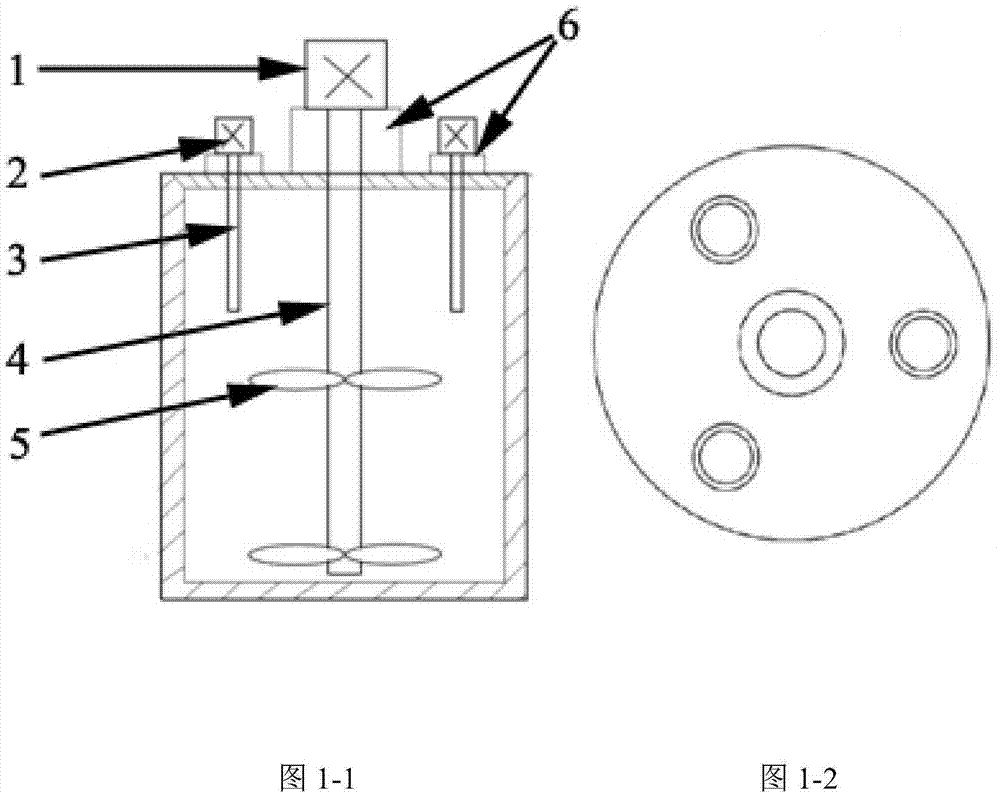

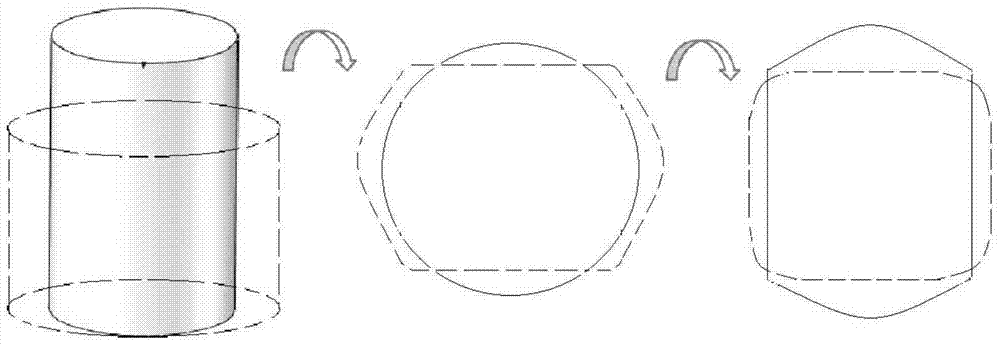

[0057] The preparation method of the high-zinc deformed magnesium alloy Mg-(8-12)Zn-(0.5-1.5)Ca-(0.5-1.0)MM of the present invention comprises:

[0058] 1 alloy melting

[0059] The materials are prepared according to the weight percentage of the magnesium alloy components described in the present invention, and each element is added in the form of pure metal. Raise the temperature of the preheating furnace to 300°C-400°C, and raise the temperature of the melting furnace to 600°C-850°C (the preheating furnace is a resistance furnace, and the melting furnace is a temperature-controllable medium-frequency electromagnetic induction heating furnace), and simultaneously A protective gas (a mixed gas of argon and 134a, the volume ratio of which is about 20:1, the same below) is introduced into the furnace;

[0060] In the preheating furnace, the pure magnesium ingot is preheated for more than 5 minutes (generally 10min to 20min), to ensure that there is no water vapor on the surfac...

Embodiment 1

[0073] According to the content of the invention, the alloy Mg-8.7Zn-1.2Ca-0.5MM (wt%, all hereinafter are mass percentages) is prepared, wherein MM represents Ce-rich mixed rare earth (its mass content is 48 parts of Ce, 30 parts of La, 18 parts of Nd , 3 parts of Pr, the content of impurities in MM is about 1%, mainly Fe, Mn), and the content of other impurities in alloy ingots does not exceed 0.1%. The recovery rate of each element is calculated according to 100%.

[0074] 1 alloy melting

[0075] The materials are prepared according to the weight percentage of the magnesium alloy composition of the present invention, wherein Mg89.6kg, Zn8.7kg, Ca1.2kg, MM0.5kg, each element is added in the form of pure metal. Raise the temperature of the preheating furnace to 300°C, and raise the temperature of the melting furnace to 700°C (the preheating furnace is a resistance furnace, and the melting furnace is a temperature-controllable medium-frequency electromagnetic induction heati...

Embodiment 2

[0087] According to the content of the invention, the alloy Mg-10.4Zn-1.5Ca-1.0MM (wt%, all hereinafter are mass percentages) is prepared, wherein MM represents Ce-rich mixed rare earth (its mass content is 48 parts of Ce, 30 parts of La, 18 parts of Nd , 3 parts of Pr, the content of impurities in MM is about 1%, mainly Fe, Mn), and the content of other impurities in alloy ingots does not exceed 0.1%. The recovery rate of each element is calculated according to 100%.

[0088] 1 alloy melting

[0089] The materials are prepared according to the weight percent of the magnesium alloy components of the present invention, wherein Mg87.1kg, Zn10.4kg, Ca1.5kg, MM1.0kg, each element is added in the form of pure metal. Raise the temperature of the preheating furnace to 350°C, and raise the temperature of the melting furnace to 750°C (the preheating furnace is a resistance furnace, and the melting furnace is a temperature-controllable intermediate frequency electromagnetic induction h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com