Production method of sulfuric acid dew-point corrosion resistance hot rolled sheet

A production method and dew point corrosion technology, applied in the field of hot-rolled steel plate production, can solve the problems of insufficient passivation layer on the metal surface and unstable acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

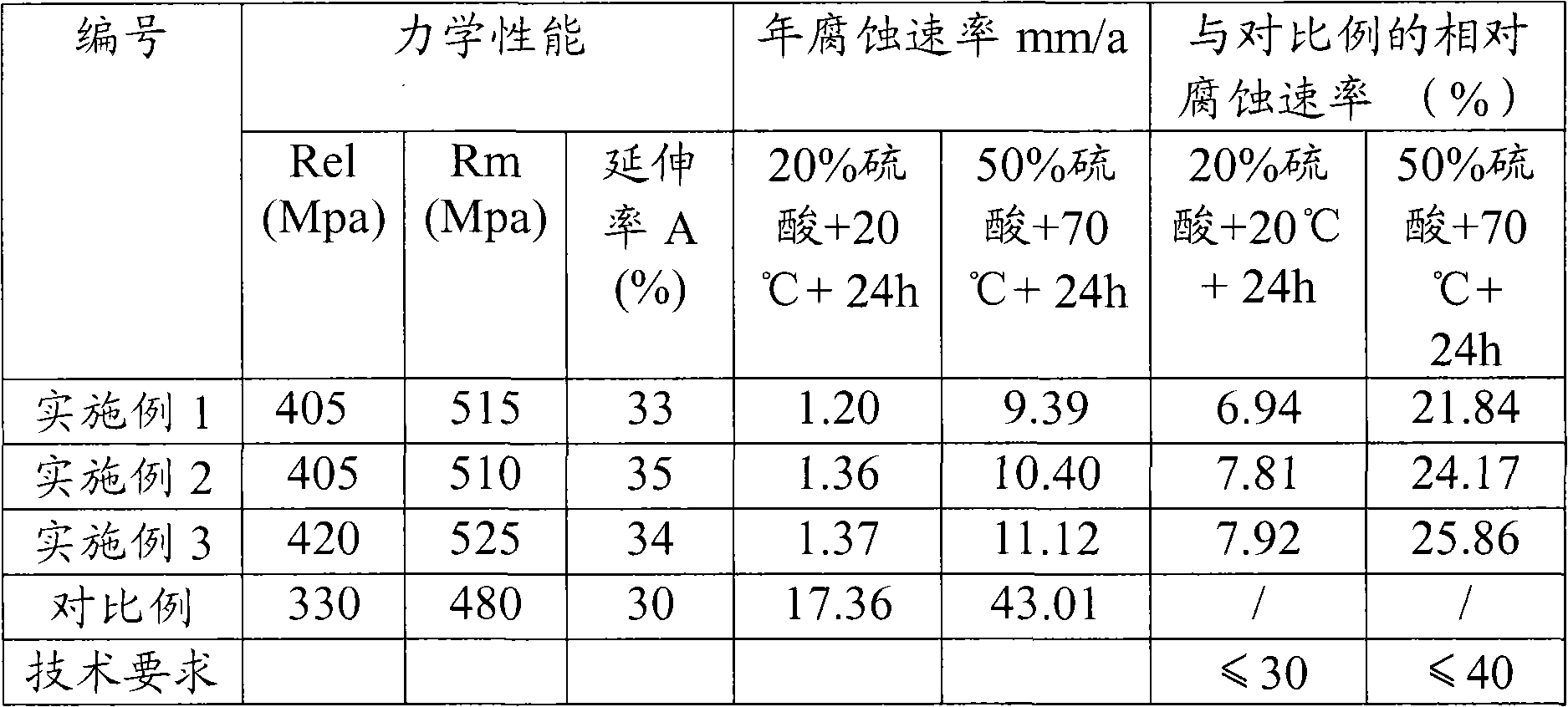

Embodiment 1

[0029] a. Smelting molten steel: The smelting equipment is a 120-ton top-blown converter, and the semi-steel molten steel in the blast furnace is used as a raw material. For molten steel tanks, add 0.5 tons of aluminum-iron alloy (Anyang Jiaxin Refractories Co., Ltd.) for pre-deoxidation when 1 / 3 of the steel is tapped, and then add 50kg of pitch coke (Panzhihua Yangcheng Metallurgical Accessories Co., Ltd.) and 900Kg of silicon to the deoxidized molten steel. Manganese alloy (Dechang Ferroalloy Co., Ltd.), 130kg Fe-Ti40 alloy (the weight ratio of Fe and Ti is 3: 2) (Panzhihua Yangcheng Ferroalloy Branch), 120kg antimony beads (Changsha Antimony Products Factory), thereby producing a product containing Molten steel with the following composition (based on the total weight of molten steel): 0.09% of C, 0.29% of Si, 0.75% of Mn, 0.013% of P, 0.004% of S, 0.60% of Cr, 0.21% of Ni, 0.018% Ti, 0.32% Cu, 0.08% Sb, 0.034% Al, 0.0044% N, and the rest is Fe. Subsequently, the molten s...

Embodiment 2

[0037] The preparation mode of molten steel and process are similar to embodiment 1, and molten steel charge is 137 tons, and the molten steel composition of making is: the C of 0.08%, the Si of 0.32%, the Mn of 0.73%, the P of 0.015%, the P of 0.005% S, 0.58% Cr, 0.20% Ni, 0.02% Ti, 0.28% Cu, 0.08% Sb, 0.048% Al, 0.0046% N, and the rest is iron. Use this molten steel to produce acid-resistant steel. The heating temperature (that is, the rolling temperature of the slab) is 1225°C, the rolling start temperature (that is, the rough rolling temperature) is 1139°C, and the number of rough rolling is 6 times, and the thickness is reduced by 27.8mm each time. , the rough rolling outlet thickness is 33mm, the reduction distribution in the finishing rolling process is 33mm→26mm→20mm→15mm→10mm→7mm→4mm, the final rolling temperature is 885°C, the coiling temperature is 700°C, the finished product room temperature Rel is 405MPa, Rm is 510MPa, elongation 35%, excellent cold bending perfor...

Embodiment 3

[0039] The preparation mode of molten steel and process are similar to embodiment 1, and molten steel charge is 140 tons, and the molten steel composition of making is: the C of 0.07%, the Si of 0.30%, the Mn of 0.74%, the P of 0.013%, the P of 0.007% S, 0.60% Cr, 0.22% Ni, 0.021% Ti, 0.27% Cu, 0.08% Sb, 0.044% Al, 0.0040% N, and the rest is iron. Use this molten steel to produce acid-resistant steel, the heating temperature is 1240°C, the rolling start temperature is 1138°C, the number of rough rolling is 6 times, the thickness is reduced by 27.8mm each time, the rough rolling exit thickness is 33mm, and the reduction distribution in the finishing rolling process is 33mm→24mm →16mm→10mm→7mm→4mm, the final rolling temperature is 890°C, the coiling temperature is 660°C, the finished product room temperature Rel is 420MPa, Rm is 525MPa, the elongation is 34%, and the cold bending performance is excellent, at 20% sulfuric acid + 20°C + Under the test condition of constant tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rm | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com