Zirconium boride based composite ceramic material thermocouple and preparation method thereof

A complex-phase ceramic and zirconium boride-based technology is applied in the field of ceramic material thermocouples and their preparation, which can solve the problems of difficult application of thermocouples, and achieve the effects of improved temperature measurement range, good electrical conductivity and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

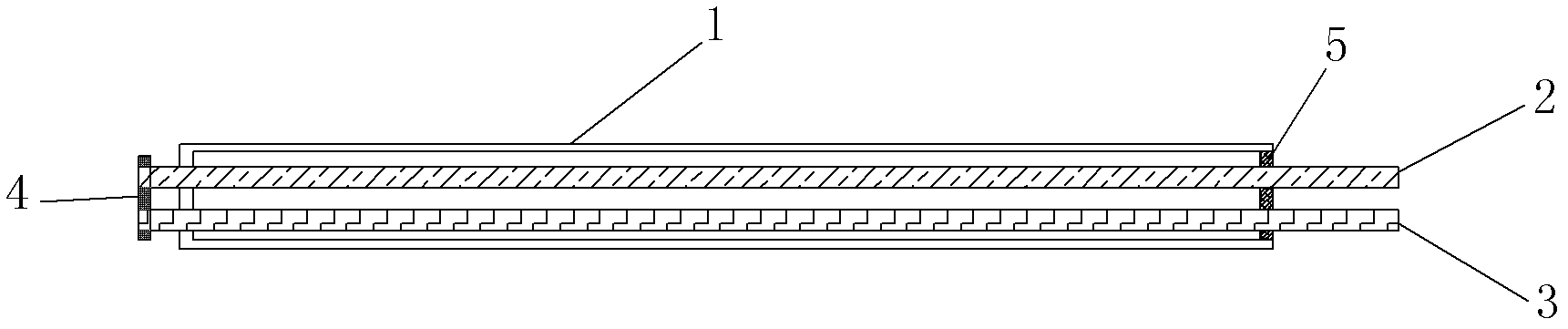

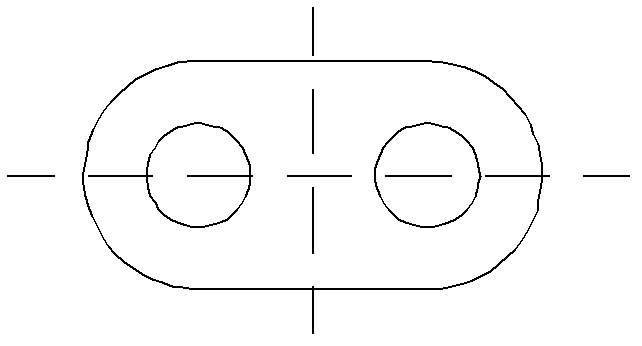

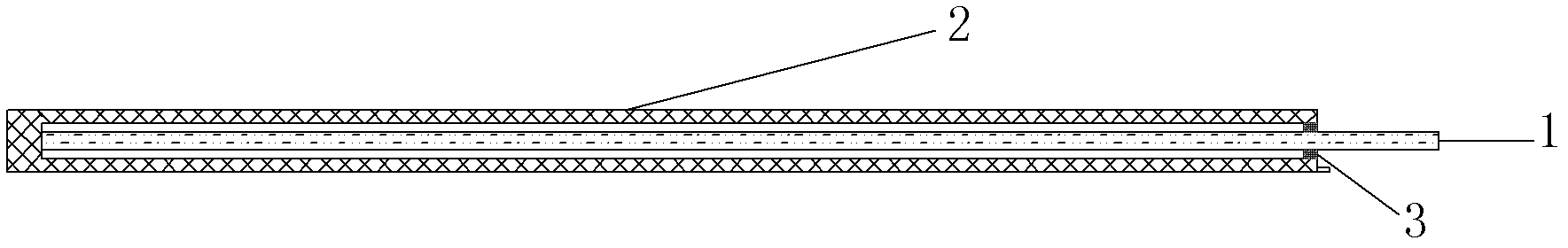

[0018] Specific Embodiment 1: A zirconium boride-based composite ceramic material thermocouple of this embodiment includes a positive electrode and a negative electrode; wherein, the positive electrode is composed of 30% to 95% ZrB by volume percentage 2 , 5% to 40% of SiC and 0 to 30% of additives, and the negative electrode is made of 60% to 95% of ZrB by volume 2 And 5%~40% SiC and 0~30% additives.

[0019] The advantages of this embodiment are: this embodiment adopts hot pressing sintering to reduce the voids in the material, and improve the material density, mechanical properties and oxidation resistance. At the same time, the reduction of the sintering temperature can also improve the production efficiency and reduce the cost. The material system of zirconium boride-silicon carbide and other additives used in this embodiment has good mechanical properties, oxidation resistance and corrosion resistance at high temperatures. At the same time, because the material system ...

specific Embodiment approach 2

[0021] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the additives are AlN, Si 3 N 4 , C, MoSi 2 , B 4 C, BN, Al 2 o 3 One or several of them are mixed in any ratio. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiments one to two is: ZrB 2 The average particle size is 0.1-10 μm. Others are the same as the specific embodiment 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com