Quick forming method for complex structure of shape memory alloy based on multi-field auxiliary adjusting control

A technology of memory alloy and complex structure, which is applied in the field of shape memory alloy, can solve the problems of low efficiency of material addition and complicated process, and achieve the effect of high material utilization rate, uniform structure and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

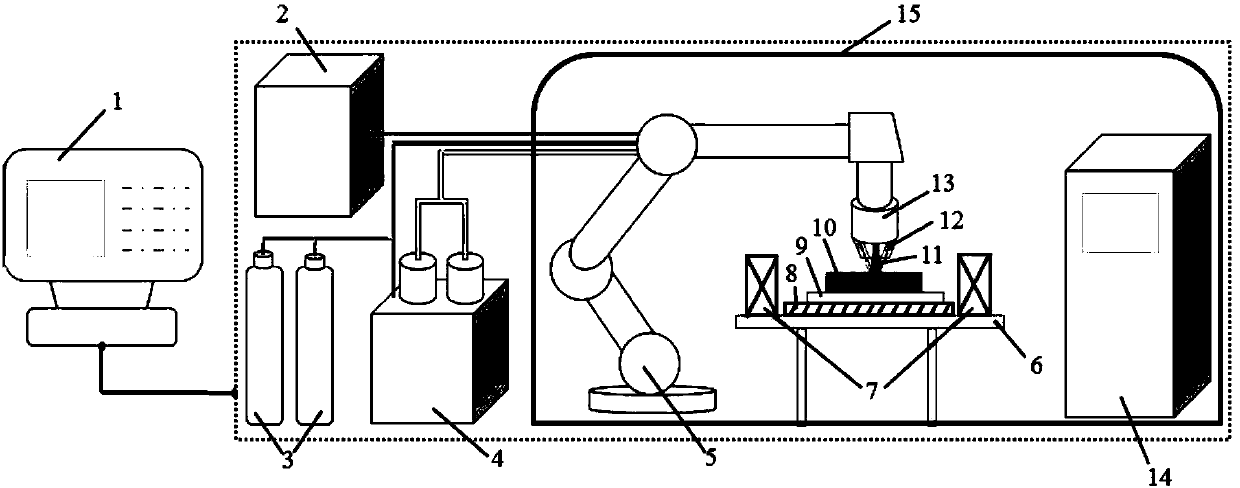

[0016] Specific implementation mode 1: In this implementation mode, the rapid prototyping method of the shape memory alloy complex structure based on multi-field assisted regulation is implemented according to the following steps:

[0017] 1. According to the atomic ratio of 1.2 to 1.5:1, the Ni powder and Ti powder are ball milled and mixed evenly, and the shape memory alloy powder material is obtained after drying;

[0018] 2. Use 3D drawing software to construct the structural part model, import the structural part model into the additive path planning software in STL format, and then plan the additive path of the entire structural part model, and output the additive path planning results in G code Format export to the additive control system;

[0019] 3. Put the shape memory alloy powder material obtained in step 1 into the powder feeder of the plasma arc additive manufacturing equipment, put the substrate, ultrasonic generator and magnetic field generator into the protect...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment is different from Embodiment 1 in that the particle size of Ni powder and Ti powder in Step 1 is 50-150 um.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that the ball milling and drying process in Step 1 is protected by argon.

[0024] In this embodiment, the powder is protected from oxidation by argon protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com