Production method of aluminium foil for electrode of electrolytic capacitor

A technology of electrolytic capacitor and production method, applied to belt and foil smelting and casting, can solve the problems of uneven surface of ingot, large energy consumption and high energy consumption, and achieve the effects of shortening production process, improving yield and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

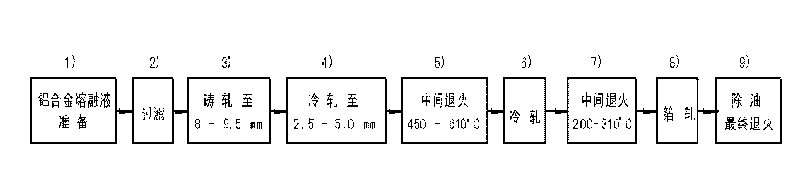

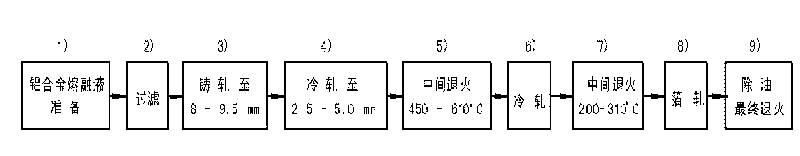

Method used

Image

Examples

Embodiment 1

[0021] For example: the product is an aluminum foil for the anode of a high-voltage electrolytic capacitor, the thickness of the finished aluminum foil is 0.11mm, and the chemical composition range of the aluminum foil is: Al purity > 99.99%, Fe < 14ppm, Si < 14ppm, Cu: 30-50ppm;

[0022] According to the production method of the present invention, the high-purity aluminum ingot (the aluminum purity is 99.995%) produced by the three-fine electrolysis method is melted to 730-750°C, and then copper, silicon, iron elements and Refining, slag removal and gas removal, detection and control of each component of aluminum water in the above target composition, and control of the gas content in aluminum water below 0.12 ml / 100 g of aluminum water; after testing, the chemical composition of the melted aluminum alloy melt The composition is Al with a purity of 99.992%, Cu: 41ppm, Si: 11ppm, Fe: 9ppm, and the rest are unavoidable impurities; and other methods to adjust the component conte...

Embodiment 2

[0026] For example, the product is an aluminum foil material for electrolytic capacitor electrodes, with a thickness of 0.12mm, a chemical composition of Al purity: 99.9% or above, and containing Si: 2-50ppm, Fe: 2-50ppm, Cu: 15-150ppm, Zn: 1- 80ppm and Pb: 0.1-3ppm, containing at least one of Zr and V at 11ppm or more and a total of 11-100ppm, further containing Ti: 1-30ppm, and at least one of Mn, Ga, Mg, and Ca 1ppm or more and a total of 1-50ppm, and at least one of In, Sn, and Sb at 1ppm or more and a total of 1-30ppm, B content is limited to 2ppm or less, and the rest is composed of aluminum and impurities;

[0027] According to the production method of the present invention, the high-purity aluminum ingot (aluminum purity is 99.995%) produced by the three-fine electrolysis method is melted to 730-750 ° C, and then the listed elements are added according to the above range, refining, deslagging and degassing, detection and Control the components of the aluminum water in ...

Embodiment 3

[0030]For example, the product is an aluminum foil material for electrolytic capacitor electrodes, with a thickness of 0.08mm, and contains Si: 0.01-0.30%, Fe: 0.01-0.30%, Ni: 0.0021-0.05%, Cu: more than 0.01%-less At 0.10%, it also contains at least one of Sn, Ga, and In in a total of 0.003-0.10%, and the rest contains aluminum and unavoidable impurities.

[0031] According to the production method of the present invention, the high-purity aluminum ingot (the purity of aluminum is 99.95%) produced by the three-fine electrolysis method is melted to 730-750 ° C, and then the listed elements are added according to the above range, refining, deslagging and degassing, detection and Control the components of the aluminum water in the above-mentioned target composition, and control the gas content in the aluminum water below 0.12 ml / 100 grams of aluminum water; after testing, the chemical composition of the melted aluminum alloy melt is Al with a purity of 99.873%, Cu: 0.017%, Si: 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com