Extra-coarse hard alloy parcel powder and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

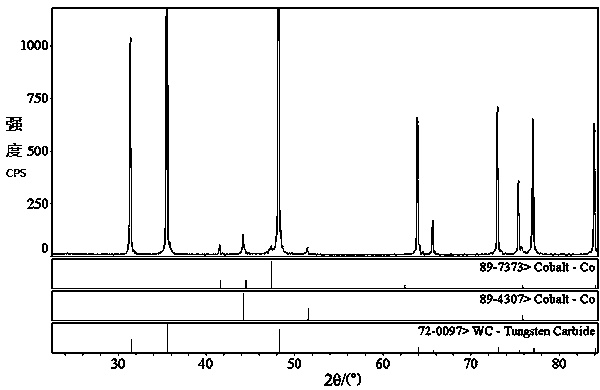

[0034] Tungsten carbide - 6wt% cobalt ultra-coarse cemented carbide coating powder.

[0035] As a nucleating agent, 94 g of tungsten carbide powder having an average Fischer particle size of 3 μm was used. 24.2g CoCl 2 ·6H 2 O dissolved in water, prepared to 65g L -1 CoCl 2 solution, heated to 50°C in a water bath. Pour tungsten carbide powder into CoCl 2 solution, constant temperature and mechanical stirring for 30min. Dissolve 15.9g ammonium oxalate in water to prepare 68.2g L -1 ammonium oxalate solution, heated to 50°C in a water bath. Then pour the ammonium oxalate solution as a precipitant into the mixed slurry, mechanically stir at a constant temperature for 30 minutes, then stop heating, and continue to mechanically stir for 60 minutes, so that the generated cobalt oxalate precipitates and wraps on the surface of the carbide particles, and the slurry is cooled to 25°C After filtering, wash once with clean water, and then dry in a constant temperature drying ove...

Embodiment 2

[0037] Tungsten carbide-0.5wt% vanadium carbide-8wt% cobalt ultra-coarse cemented carbide coating powder.

[0038] As the nucleating agent, tungsten carbide with an average Fischer particle size of 4 μm and vanadium carbide powder with an average Fischer particle size of 1.5 μm were used. Among them, the tungsten carbide powder is 91.5g, and the vanadium carbide powder is 0.5g. 32.3gCoCl 2 ·6H 2 O dissolved in water, prepared to 65g L -1 CoCl 2 solution, heated to 60°C in a water bath. Pour tungsten carbide powder and vanadium carbide powder into CoCl 2 solution, constant temperature and mechanical stirring for 40min. Dissolve 21.2g ammonium oxalate in water to prepare 34.1g L -1 ammonium oxalate solution, heated to 60°C in a water bath. Then pour the ammonium oxalate solution as a precipitant into the mixed slurry, mechanically stir at a constant temperature for 50 minutes, then stop heating, and continue mechanically stirring for 40 minutes, so that the generated cob...

Embodiment 3

[0040] Tungsten carbide-1.5wt% chromium carbide-9wt% cobalt ultra-coarse cemented carbide coating powder.

[0041]As the nucleating agent, tungsten carbide with an average Fischer particle size of 4.5 μm and chromium carbide powder with an average Fischer particle size of 1.6 μm were used. Among them, tungsten carbide powder is 89.5g, and chromium carbide powder is 1.5g. 43gCoSO 4 ·7H 2 O dissolved in water, prepared to 77.5g L -1 CoSO 4 solution, heated to 70°C in a water bath. Pour tungsten carbide powder and chromium carbide powder into CoSO 4 solution, constant temperature and mechanical stirring for 40min. Dissolve 23.9g ammonium oxalate in water to prepare 68.2g L -1 ammonium oxalate solution, heated to 70°C in a water bath. Then pour the ammonium oxalate solution as a precipitant into the mixed slurry, mechanically stir at a constant temperature for 40 minutes, then stop heating, and continue mechanically stirring for 60 minutes, so that the generated cobalt oxa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com