High-temperature-boiling-resistant low-temperature-toughness polyolefin plastic as well as preparation method and application thereof

A low-temperature toughness and polyolefin technology, applied in the field of plastic packaging, can solve problems such as poor component compatibility, and achieve the effects of improving heat resistance, improving compatibility, and excellent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

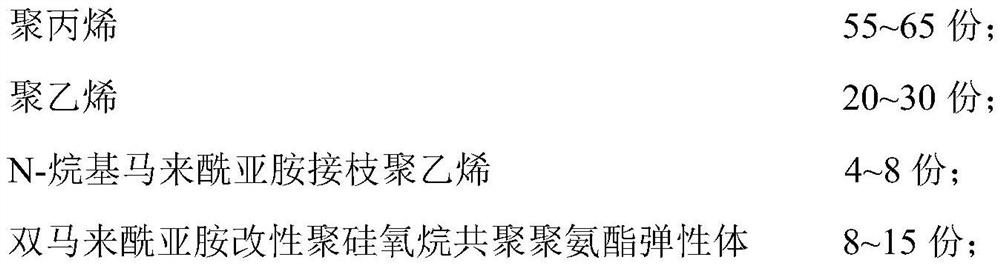

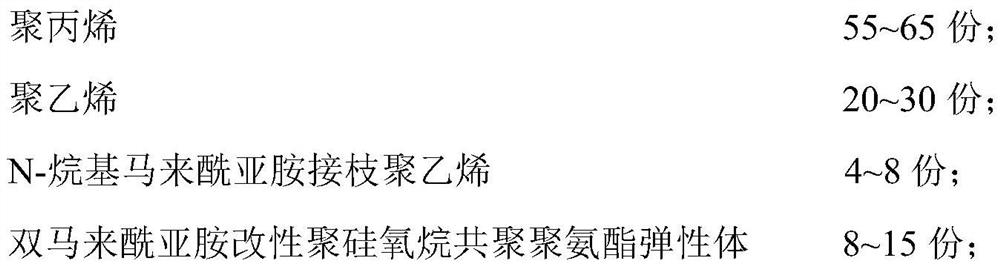

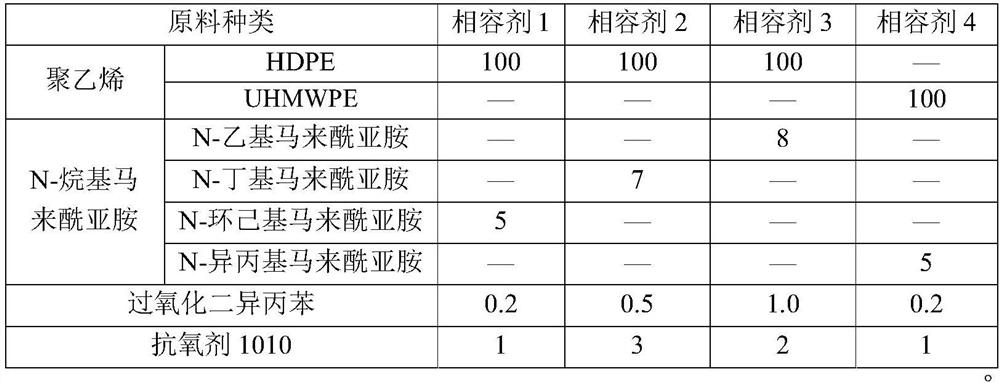

[0067] This embodiment provides a series of low temperature tough polyolefin plastics resistant to high temperature cooking.

[0068] According to the formula in Table 4, polypropylene, polyethylene, N-alkylmaleimide grafted polyethylene and bismaleimide modified polysiloxane copolymerized polyurethane elastomer were put into the mixer for Mix until uniform, then extrude and granulate through a twin-screw extruder at a temperature of 200-260° C. (see Table 3 for details) and a rotational speed of 100-150 rpm.

[0069] Table 3 Processing temperature (° C.) in each zone of the twin-screw extruder of Examples 1 to 8

[0070] District I Zone II Zone III District IV Temperature setting / ℃ 260 260 230 210

[0071] .

[0072] Table 4 Low temperature toughness polyolefin plastic raw materials and dosage (g) resistant to high temperature cooking

[0073]

[0074]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com