A kind of preparation method of high-strength, high-modulus, high-elasticity polyurethane film

A polyurethane film, high-strength and high-modulus technology, which is applied in the field of film materials, can solve the problems of difficult polyurethane film and elastic decline, and achieve the effect of low cost, high controllability and widening application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of high-strength, high-modulus and high-elasticity polyurethane film, described preparation method is carried out according to the following steps:

[0033] a Polyurethane solution preparation

[0034] Put one of polyether polyurethane or polyester polyurethane or polyester-polyether polyurethane into N,N-dimethylformamide with a mass fraction of 98% to 99%, and the room temperature is 8-38 Stir mechanically for 0.5-1 h at ℃ and then vacuum defoam to obtain a polyether-based polyurethane solution or a polyester-based polyurethane solution or a polyester-polyurethane solution with a solid content of 10-25% and a dynamic viscosity of One of the ether type polyurethane solutions, wherein the stirring rate is 800-3000r / min.

[0035] b coagulation bath preparation

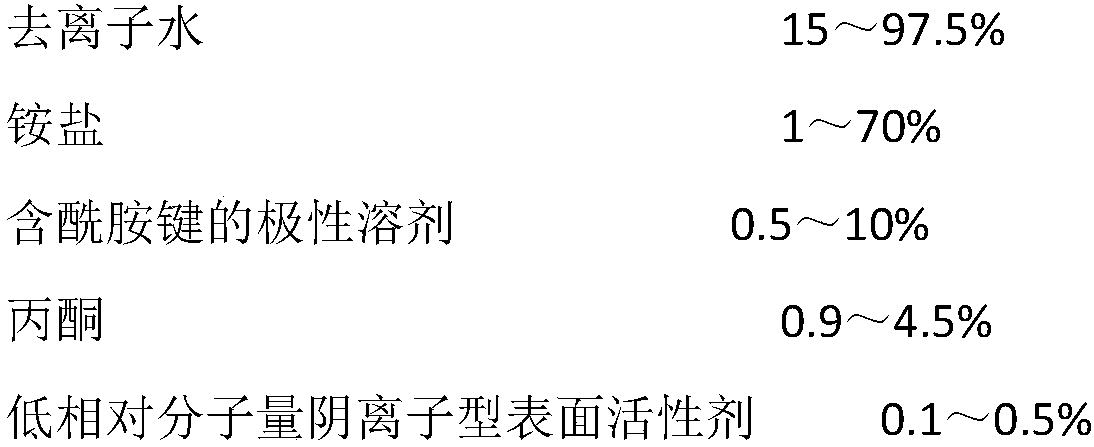

[0036] According to the following mass percentage:

[0037] Deionized water 15~97.5%

[0038] Ammonium salt 1~70%

[0039]Polar solvent containing amide bond 0.5~10%

[0040] Acetone 0....

Embodiment 1

[0050] a Polyurethane solution preparation

[0051] Put polyether polyurethane into N,N-dimethylformamide with a mass fraction of 98%, mechanically stir it at room temperature for 0.5 h, and then vacuum defoam to obtain solid content of 15%, dynamic viscosity It is a polyether polyurethane solution at 200mPa·s, and the stirring speed is 800r / min.

[0052] b coagulation bath preparation

[0053] 70g ammonium nitrate, 10g formamide, 4.5g acetone and 0.5g relative molecular weight are put into 15g deionized water with conductivity 16MΩ·cm to obtain mixed solution, then the temperature of mixed solution is raised After heating to 25°C and stirring mechanically for 3 hours, a coagulation bath was obtained, wherein the stirring rate was 800 r / min.

[0054] c Polyurethane solution scraping

[0055] Pour the polyether polyurethane solution prepared in step a into a clean polytetrafluoroethylene board with a thickness of 0.5mm, a length of 1.5m and a width of 0.7m, and scrape it wit...

Embodiment 2

[0061] aPolyurethane solution preparation

[0062] Put the polyester polyurethane into N,N-dimethylformamide with a mass fraction of 99%, mechanically stir it for 1 h at room temperature at 18°C, and then vacuum defoam to obtain a solid content of 20% and a dynamic viscosity It is a polyester polyurethane solution of 3000mPa·s, and the stirring rate is 1200r / min.

[0063] b coagulation bath preparation

[0064] Put 60g of ammonium chloride, 8gN, N-dimethylformamide, 1.5g of acetone and 0.5g of sulfonate surfactant with a relative molecular weight of 400 into 30g of deionized water with a conductivity of 15MΩ cm to obtain a mixed solution, Then the temperature of the mixed solution was increased to 50° C. and mechanically stirred for 4 hours to obtain a coagulation bath, wherein the stirring rate was 1100 r / min.

[0065] c Polyurethane solution scraping

[0066] Pour the polyester polyurethane solution prepared in step a into a clean polytetrafluoroethylene plate with a thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com