A kind of high-strength silk protein nanofiber membrane and its preparation method

A nanofiber membrane and nanofiber technology, which is applied in the field of high-strength silk protein nanofiber membrane and its preparation, can solve the problems of measurement and regenerated silk nanofiber membrane fragility and fragility, and achieve the improvement of tensile mechanical properties and simple preparation method The effect of easy operation and high tensile mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a method for preparing a high-strength silk protein nanofiber membrane, comprising the following steps:

[0028] S1: Freeze-dry the aqueous solution of high-crystalline fibroin nanofibers to obtain freeze-dried powder of silk protein nanofibers; the crystallinity of silk protein fibers in the aqueous solution of high-crystalline fibroin nanofibers is ≥ 40%, the diameter is 10-30 nm, and the length is 200-200 nm. 2000nm;

[0029] S2: Dissolving the lyophilized powder of silk protein nanofibers in a formic acid solution to obtain a formic acid solution of silk protein nanofibers;

[0030] S3: volatilize formic acid in the formic acid solution of the silk protein nanofibers to form a film to obtain a silk protein nanofiber film.

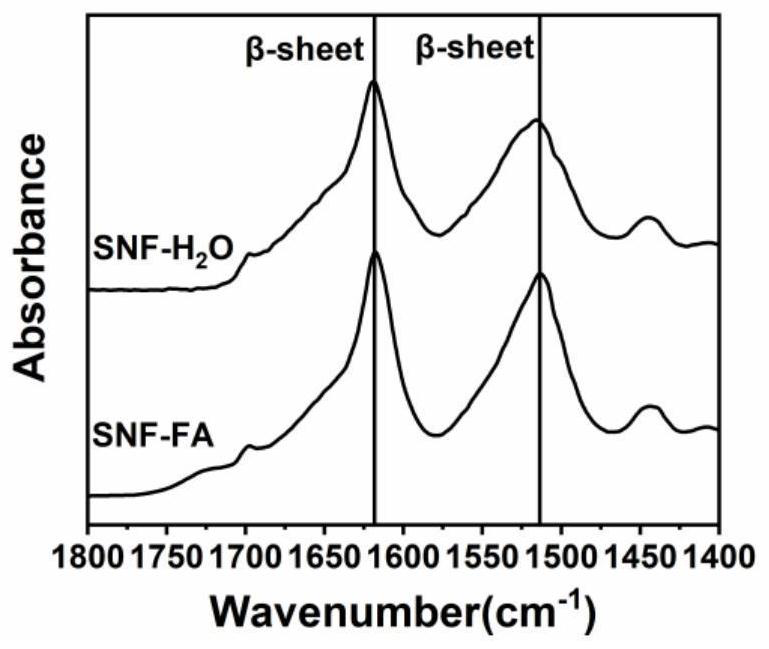

[0031] The high crystal fibroin nanofibers used in the method provided by the invention have a beta-sheet crystal structure and good stability, and can still maintain its original secondary structure and nanofiber morpholo...

Embodiment 1

[0047] (1) freeze-drying 0.5% silk protein nanofiber aqueous solution to obtain silk protein nanofiber freeze-dried powder;

[0048] (2) Dissolving the lyophilized powder of silk protein nanofibers in formic acid solution at 60° C. for 0.5 h to obtain a 10% formic acid solution of silk protein nanofibers;

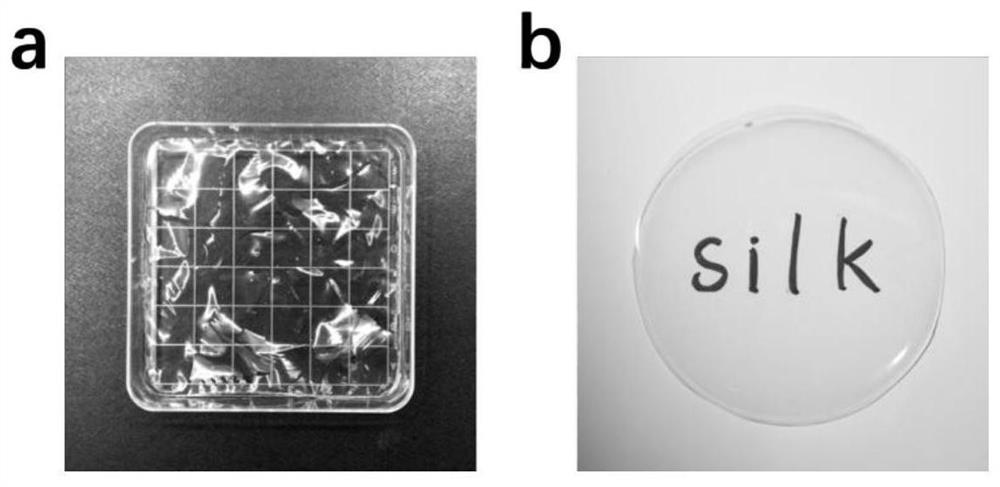

[0049] (3) A 10% formic acid solution of silk protein nanofibers was volatilized at 60° C. for 2 hours to prepare a silk protein nanofiber film with a thickness of 30 μm.

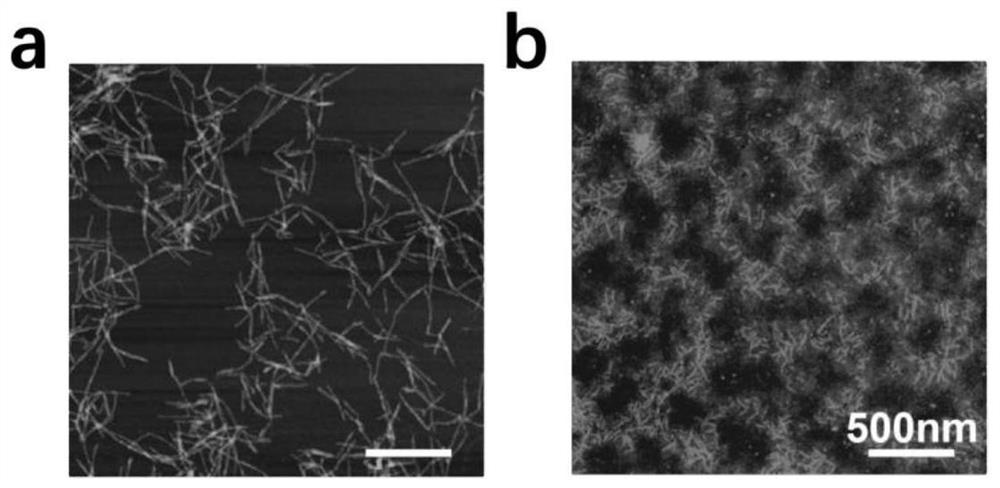

[0050] figure 1 Atomic force microscope pictures of silk protein nanofibers prepared in Example 1 of the present invention dissolved in water (a) and formic acid (b) respectively; from figure 1 It can be seen that: in the aqueous solution, the silk fibroin in the formic acid solution all presents the shape of nanofibers; the length of the nanofibers in the aqueous solution is distributed in 200-1000nm, while the length of the nanofibers in the formic acid is reduced to 50-200nm, and the shorter fibers ...

Embodiment 2

[0059] (1) freeze-drying 2% silk protein nanofiber aqueous solution to obtain silk protein nanofiber freeze-dried powder;

[0060] (2) Dissolving the lyophilized powder of silk protein nanofibers in formic acid solution at 20° C. for 1 hour to obtain a 2% formic acid solution of silk protein nanofibers;

[0061] (3) A 2% silk protein nanofiber formic acid solution was volatilized at 20° C. for 72 hours to prepare a silk protein nanofiber film with a thickness of 38 μm.

[0062] The tensile mechanical strength of the silk protein nanofiber membrane prepared in Example 2 is 69.2 MPa and 13.5 MPa in dry state and wet state, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com