Method for improving tensile strength of silica ceramic based composite material

A technology of composite materials and silica, which is applied in the field of improving the tensile strength of silica ceramic matrix composite materials, can solve the problems of reduced reliability of weapon systems, decreased impact resistance of radome/antenna window products, etc., and achieves improved tensile strength. Lower tensile strength, improved tensile mechanical properties, and the effect of increased tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

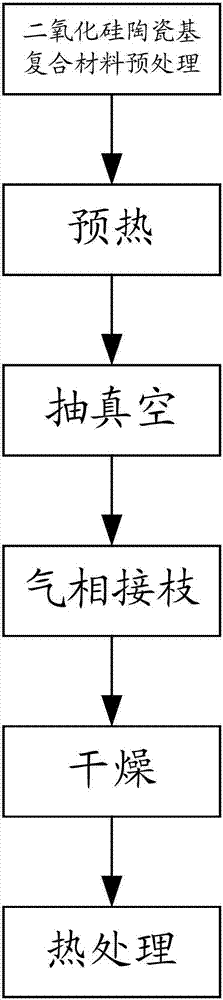

Method used

Image

Examples

Embodiment 1

[0035]Using trimethylmethoxysilane with a weight of M*7.5% (concentration: 1.25g / L) as a reagent, preheat the dried parent direction tensile specimen together with an airtight container, and then vacuumize and connect with the gas phase. Branches were dried in an oven and heat-treated at 600°C. Compared with the ungrafted samples, the average weight gain of the treated samples was 0.95%, and the average tensile strength changed from 48.578MPa to 57.653MPa, an average increase of 18.68%.

Embodiment 2

[0037] Use trimethylmethoxysilane with a weight of M*7.5% (concentration: 2.3g / L) as a reagent, preheat the dried hoop stretched sample together with a closed container, and then vacuumize and connect with the gas phase. Branches were dried in an oven and heat-treated at 600°C. Compared with the ungrafted samples, the average weight gain of the treated samples was 1.04%, and the average tensile strength changed from 27.647MPa to 34.380MPa, an average increase of 24.35%.

Embodiment 3

[0039] Using trimethylmethoxysilane with a weight of M*7.5% (concentration: 3.0g / L) as a reagent, preheat the dried hoop stretched sample together with an airtight container, then vacuumize and connect with the gas phase Branches were dried in an oven and heat-treated at 600°C. Compared with the ungrafted samples, the average weight gain of the treated samples was 0.97%, and the average tensile strength changed from 28.860MPa to 37.813MPa, an average increase of 31.02%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com