Ultrahigh-damping and high-strength metal-based composite material and preparation method thereof

A composite material and high-strength technology, applied in the direction of chemical instruments and methods, metal layered products, lamination devices, etc., can solve the problems of long production cycle, low success rate, complex process, etc., and achieve improved damping performance and high mechanical strength. The effect of damping and increasing energy dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This example is a comparative example.

[0041] CuAlMn shape memory alloy without any reinforcement phase prepared by casting process:

[0042] According to the CuAlMn shape memory alloy, Al accounts for 11.9% of the total mass of CuAlMn, Mn accounts for 2.5% of the total mass of CuAlMn, and the rest is composed of Cu. Weigh the required amount of raw material pure Cu, pure Al and electrolytic Mn, after that, the Pure Cu is placed in a graphite crucible in an intermediate frequency induction heating furnace. After heating up to Cu melting, add electrolytic Mn and pure Al in turn, and stir counterclockwise. After all the raw materials are melted evenly and kept warm for 3 minutes, quickly skim off the surface scum. Then pour it into a steel mold. After the CuAlMn shape memory alloy is solidified, put it into the resistance furnace again, and raise the temperature to 900 ° C. After keeping it for 10 minutes, put it into water at room temperature and quench it. CuAlMn sha...

Embodiment 2

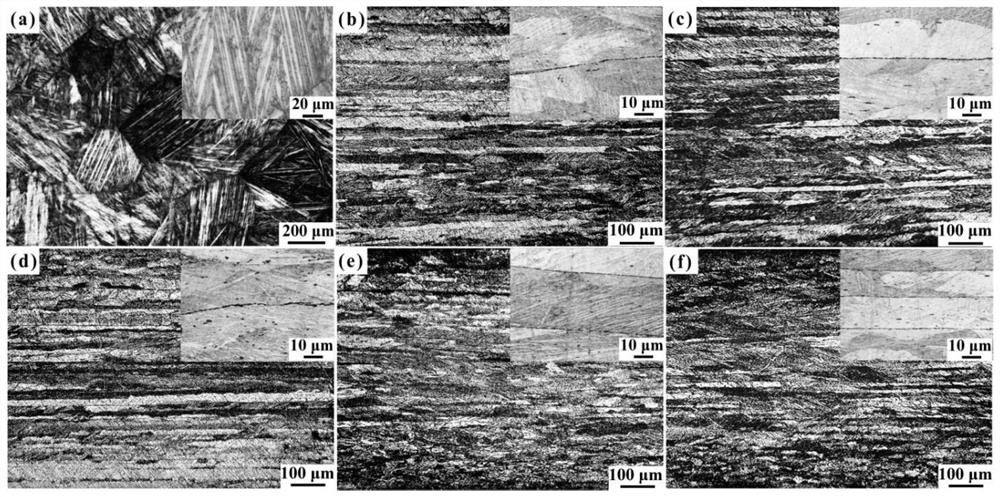

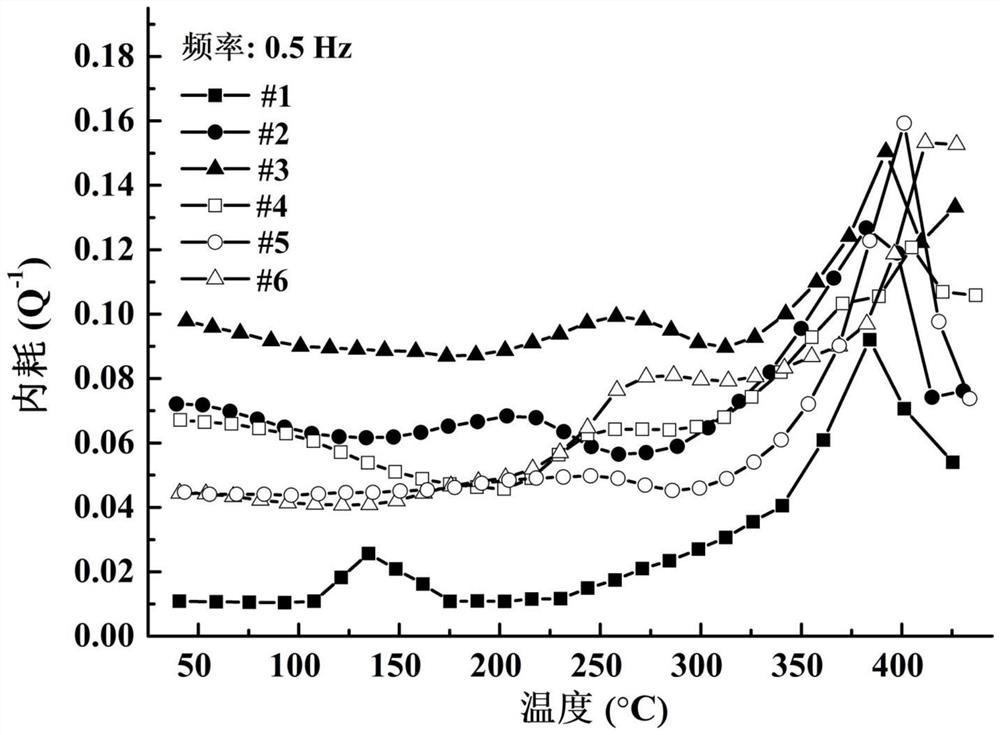

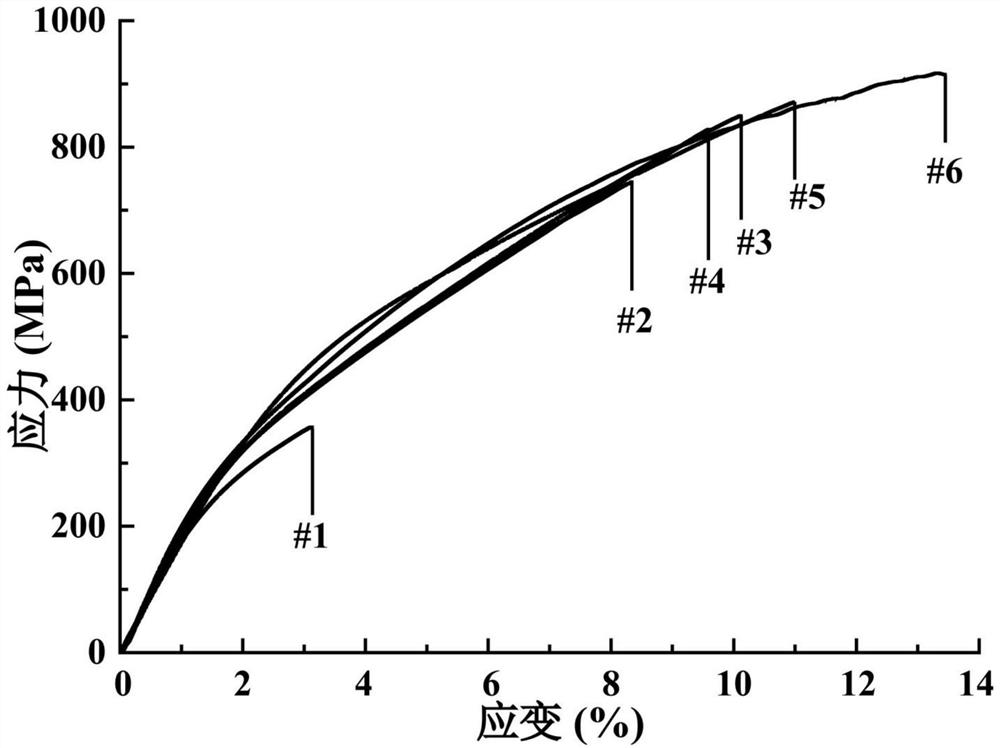

[0046] It is a multilayer graphene / CuAlMn shape memory alloy layered composite material with ultra-high damping and high strength, and its composition is Cu-11.9Al-2.5Mn+1.0wt.%Cu 51 Zr 14 Inoculant plus 0.05wt.% multilayer graphene, the room temperature damping of the composite material is 0.0721, the tensile strength is 750.36MPa, and the elongation after fracture is 8.34%. The number of layers of the CuAlMn shape memory alloy laminated sheet is 17 layers .

[0047] The preparation method of the above-mentioned multilayer graphene / CuAlMn shape memory alloy layered composite material with ultra-high damping and high strength, the specific steps are as follows:

[0048] The first step is to prepare CuAlMn shape memory alloy laminated sheet:

[0049] Using the CuAlMn shape memory alloy ingot made by a refinement method of CuAlMn shape memory alloy grains disclosed in CN105568019B, the CuAlMn shape memory alloy ingot is sliced using a wire cutting machine to obtain a single ...

Embodiment 3

[0057] It is a multilayer graphene / CuAlMn shape memory alloy layered composite material with ultra-high damping and high strength, and its composition is Cu-11.9Al-2.5Mn+1.0wt.%Cu 51 Zr 14 Inoculant plus 0.1wt.% multilayer graphene, the room temperature damping of the composite material is 0.0979, the tensile strength is 844.89MPa, and the elongation after fracture is 10.2%. The number of layers of the CuAlMn shape memory alloy laminated sheet is 17 layers .

[0058] In the preparation method of the multilayer graphene / CuAlMn shape memory alloy layered composite material with both ultra-high damping and high strength in this embodiment, except in the second step "take the above first step to prepare the CuAlMn shape memory alloy laminated plate 17 layers, use a scraper to evenly scrape the graphene on the surface of each layer of the plate, the amount of graphene is 0.05% of the mass fraction of the plate, in ", modify the amount of graphene to be 0.05% of the mass fraction o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com