Ferroelectric single crystal/epoxy 2-2 structure and 2-2 structure composite materials reinforced by stress plates

A composite material and ferroelectric single crystal technology, which is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problem of large equivalent noise and sound pressure , Instable performance, complex processing process and other problems, to achieve the effect of improving hydrostatic piezoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

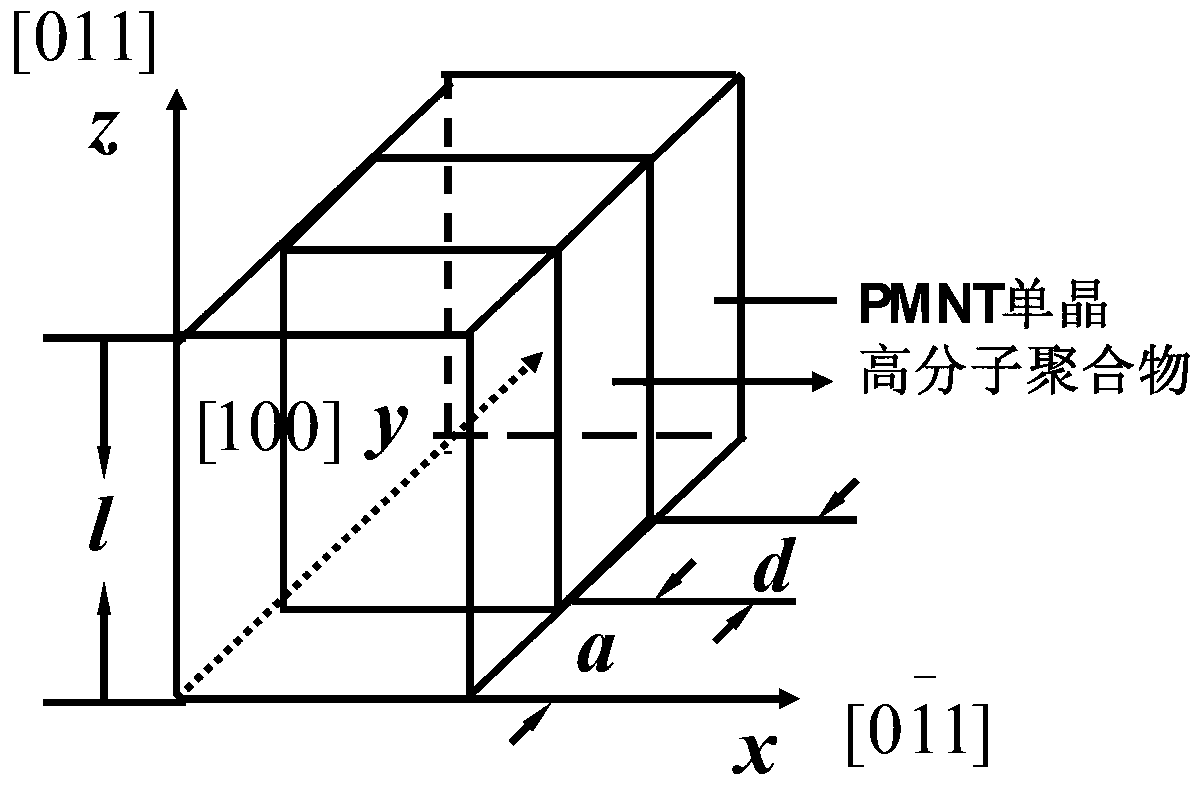

Embodiment 1

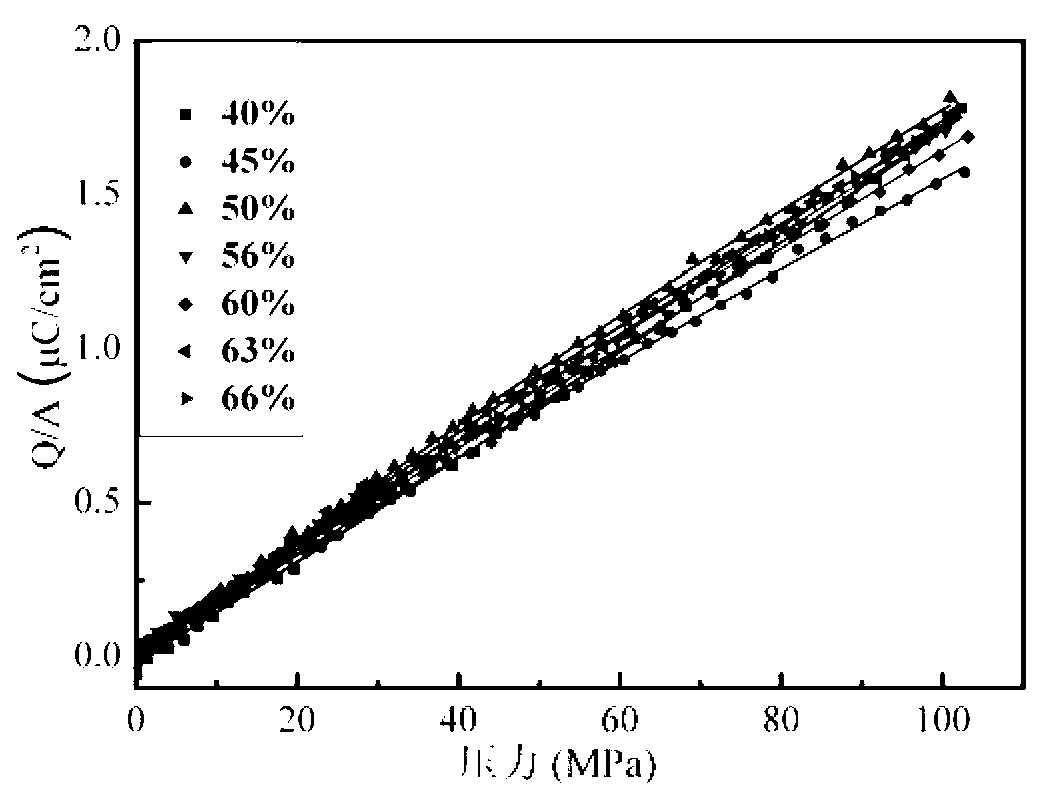

[0037] The single crystal material used in this embodiment is the trigonal phase Pb(Mg 1 / 3 Nb 2 / 3 )O 3 -PbTiO 3 Binary ferroelectric single crystal. The crystals were oriented by the Laue diffraction method, and [011], [100] and direction, and then cut into [011] oriented square pieces of 10×10×2mm for later use. Fix the sample on the sample stage of the diamond automatic dicing machine, and then use a 0.350mm diamond knife to cut the sample along the direction, the cutting depth is 2.5mm, by adjusting the cutting step to 0.58mm, 0.64mm, 0.70mm, 0.80mm, 0.87mm, 0.95mm and 1.03mm respectively, the single crystal integral number is 40% to 66%. 7 array samples. After the cutting is completed, the intact array sample is obtained, and then epoxy resin (EPO-TEK301 from Epoxy Technology Company of the United States, the mass ratio of resin / curing agent is 100:25) is poured into the sample, so that the resin is filled into the inside of the cut, at room temperature After curi...

Embodiment 2

[0044] This embodiment uses the Pb(Mg 1 / 3 Nb 2 / 3 )O 3 -PbTiO 3 Ferroelectric single crystals were fabricated into 2-2 composites. The orientation method of the single crystal and the processing technology of the 2-2 composite material are the same as in Example 1, the volume fraction of the single crystal is set to 50%, and the polymer filled in the composite material is also the same as in Example 1. Table 3 shows the basic performance test results of single crystal 2-2 composite materials with different components, and compares them with the performance of pure PMN-PT single crystal. It can be seen from Table 3 that compared with pure single crystal, the single crystal 2-2 composite materials of each component have higher electromechanical coupling coefficient and lower acoustic impedance. Figure 4 That is to say, the designer of the present invention uses the isostatic pressure test system of Xi'an Jiaotong University to measure the variation of the charge released per...

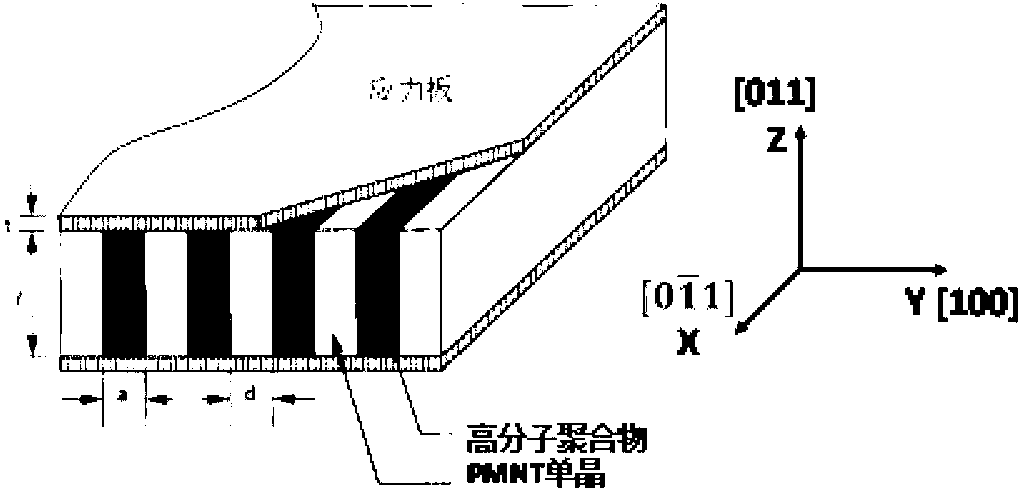

Embodiment 3

[0050] From the 2-2 composite material of the monoclinic phase and the 2-2 composite material of the trigonal phase away from the phase boundary in Example 2, lead the wires out from the upper and lower electrode surfaces, and then add a 0.3mm thick epoxy-based copper-clad laminate for each. Reinforcement yields panel-reinforced 2-2 structure single crystal composites. The epoxy conductive adhesive is used to bond the 2-2 composite material and the stress plate, and the sample can be tested after curing at room temperature for 24 hours. The method for testing and analyzing the hydrostatic piezoelectric performance of the 2-2 structure single crystal composite material strengthened by the stress plate is the same as that in Example 1. Figure 5 with Image 6 The graphs of the release charge per unit area of the monoclinic phase and the stress plate-strengthened 2-2 structure far away from the phase boundary trigonal phase as a function of pressure are given respectively. Ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com