Electric arc additive manufacturing method for flange part

A technology of additive manufacturing and electric arc, applied in the direction of additive manufacturing, additive processing, process efficiency improvement, etc., can solve the problems of difficult mass production, no spare parts available, long production cycle, etc., to achieve organization and plastic toughness optimization, Improvement of anisotropy and simplification of processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

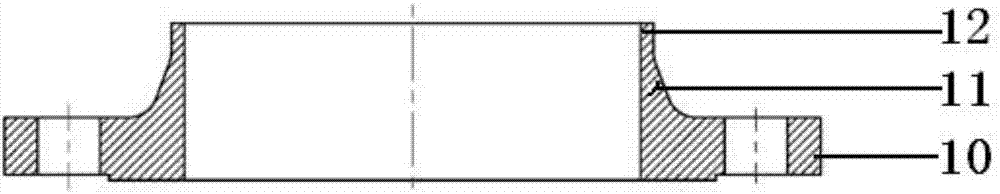

Embodiment 1

[0034] Now manufacturing DN65 stainless steel 316L flanges, offline programming to realize flange layered slicing and travel path, choose 316L substrate, argon + oxygen mixed gas protection, use 150-180A current for the bottom surface and lower neck, and the robot travel speed is 0.5-0.7m / min, overlap rate 40%-50% for spiral accumulation, the upper neck uses 120-150A current, the robot travel speed is 0.5-0.7m / min for accumulation, each layer is cleaned and polished, and the temperature between layers is monitored. Turn on the cooling device. As the printing progresses, the water level of the cooling device will gradually rise to keep the temperature below 120°C.

[0035] After the printing was completed, the excess substrate was cut off, polished for ultrasonic non-destructive testing, and no defects such as cracks, pores, and lack of fusion were found.

[0036] After the flange is dissected, the mechanical performance test is carried out. The tensile strength at room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com