Titanium alloy irregular wire material straightening device and straightening method thereof

A technology of straightening device and titanium alloy, applied in the field of titanium alloy special-shaped wire straightening device, can solve the problems that the straightening device cannot meet the surface quality of titanium alloy special-shaped material, the requirements of mass production, etc., and can meet the requirements of surface quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

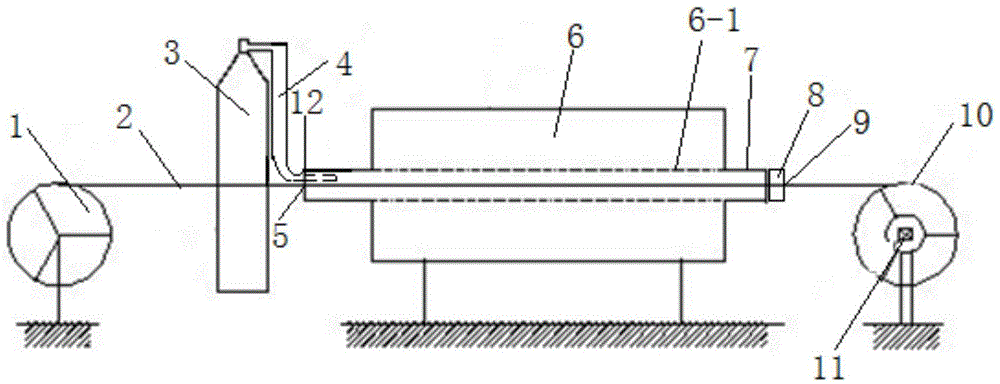

Embodiment 1

[0048] Use a titanium alloy special-shaped wire straightening device of the present invention to carry out online thermal tension straightening of the rolled δ1.04*2.8mm titanium alloy special-shaped wire 2: pretreat the special-shaped material to be straightened, and use The ratio is: HF: HNO 3 :H 2 O=1:3:20 weak acid for pickling, cleaning and drying, and then rewinding on the pay-off wheel with a diameter of 600mm to prepare for alignment; turn on the power supply of the tubular heating furnace 6, and set the furnace temperature to 850°C ;After reaching the temperature, open the 3 valves of the inert gas tank filled with argon, adjust the argon delivery rate to 12L / min, wait for 5 minutes after the argon delivery, and straighten the coil to be δ1.04*2.8mm TC4 titanium alloy The special-shaped wire 2 is drawn out from the pay-off reel 1, passes through the tubular heating furnace 6, and is fixed on the active take-up reel 10; the motor 11 is switched on, and the motor speed...

Embodiment 2

[0050] Use a titanium alloy special-shaped wire straightening device of the present invention to carry out online thermal tension straightening of the rolled δ0.8*2.2mm titanium alloy special-shaped wire 2: pretreat the special-shaped material to be straightened, and use The ratio is: HF: HNO 3 :H 2 O=1:3:20 weak acid for pickling, cleaning and drying, and then rewinding on the pay-off wheel with a diameter of 800mm to prepare for alignment; turn on the power supply of the tubular heating furnace 6, and set the furnace temperature to 950°C ;After reaching the temperature, open the 3 valves of the inert gas tank with argon gas, adjust the argon gas delivery rate to 15L / min, wait for 3 minutes after the argon gas delivery, and straighten the coil to be δ0.8*2.2mm titanium alloy special-shaped The wire material 2 is drawn out by the pay-off reel 1, passes through the tubular heating furnace 6, and is fixed on the active take-up reel 10; connects the motor 11, and sets the motor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com