Vacuum high-pressure diffusion bonding superplastic forming gas path system and control method

A diffusion joining and superplastic forming technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve problems such as product performance degradation, improve production efficiency, avoid product performance degradation, and shorten processing cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

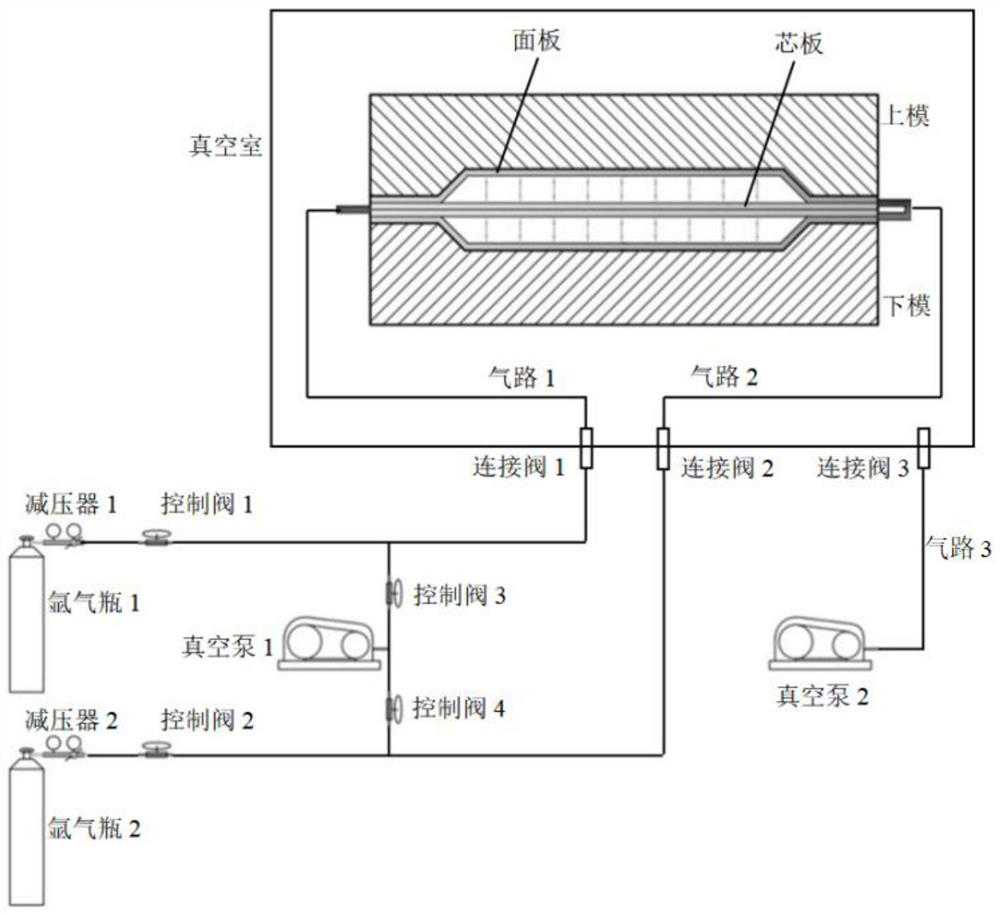

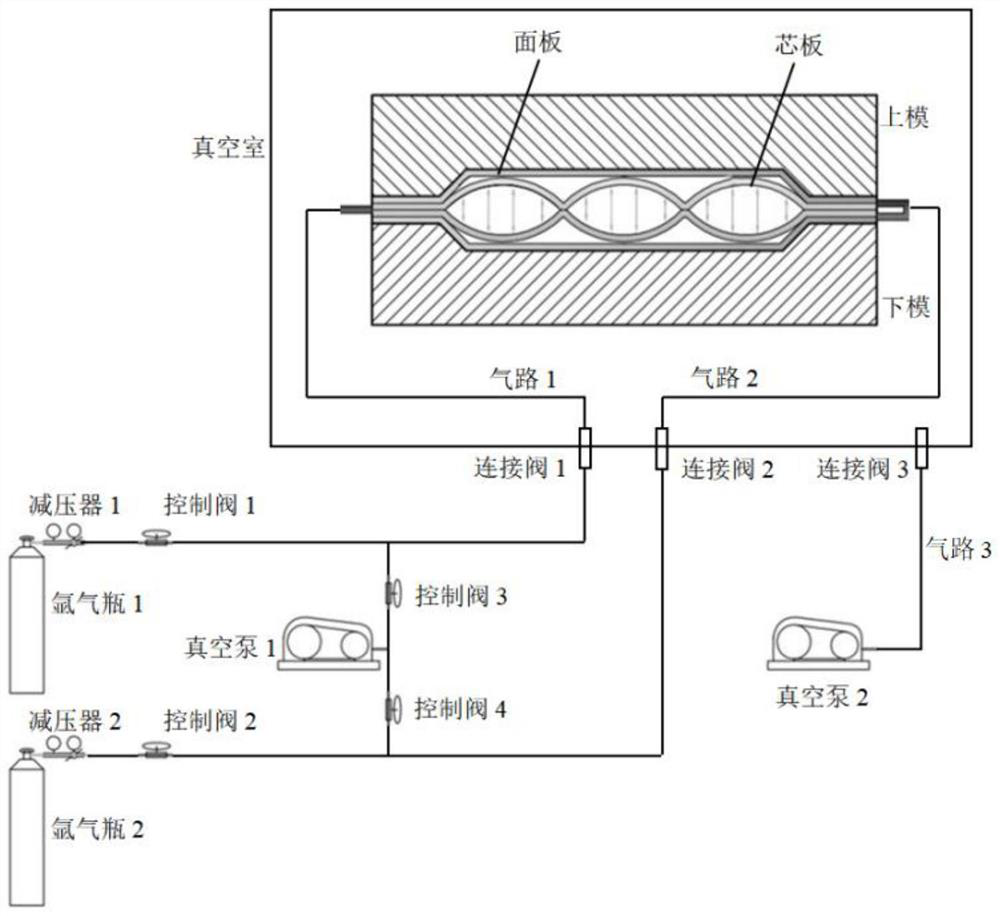

[0030] This embodiment provides a vacuum high-pressure diffusion connection / superplastic forming gas path system and control method. This method uses a titanium alloy four-layer structure as an example to introduce the vacuum high-pressure diffusion connection / superplastic forming method.

[0031] The specific method steps of the present embodiment are as follows:

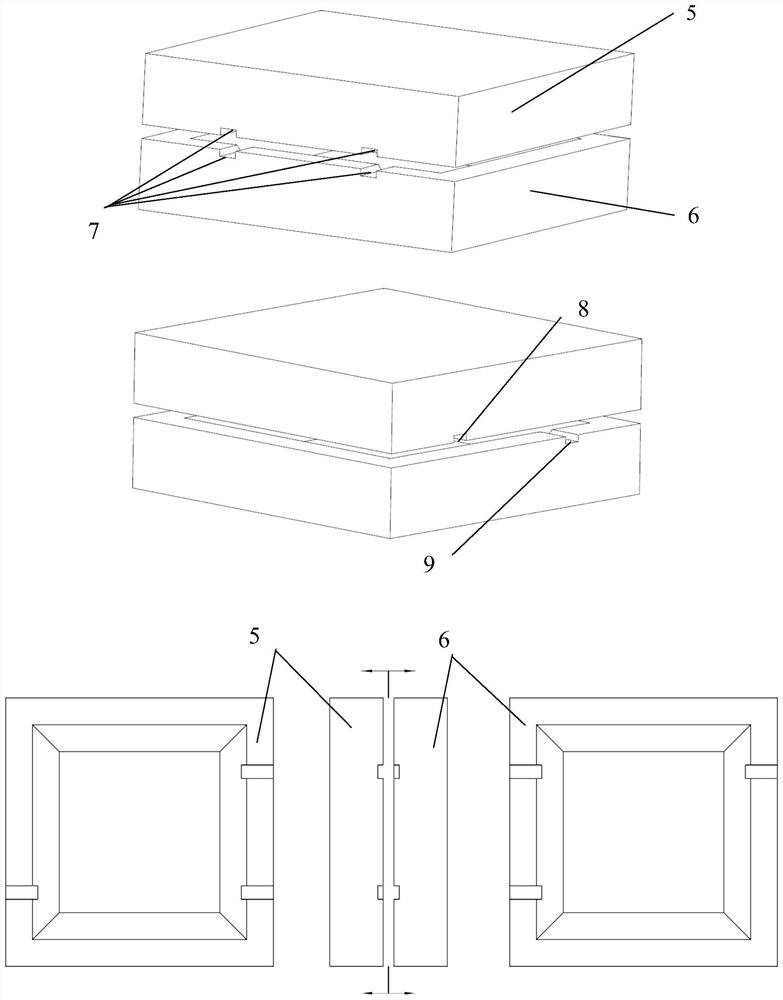

[0032]Install titanium alloy four-layer structure vacuum high pressure diffusion bonding / superplastic forming mold. Open the vacuum chamber of the equipment, place and fix the four-layer structure vacuum high-pressure diffusion connection / superplastic forming mold on the platform of the vacuum chamber; open the upper mold of the mold, put the four-layer structure blank in the cavity of the lower mold and prepare Position, then close the upper mold.

[0033] Connect the diffusion connection / superplastic forming air line and check for air tightness. Connect the core cavity of the four-layer structure with the gas p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com